Abstract

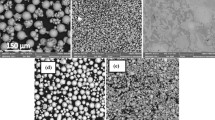

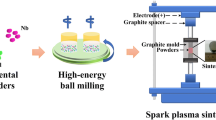

The material design concept of high-entropy alloy (HEA) is proposed for Tribaloy alloys. In this research, three HEAs are created by mixing Co-based T-800 and Ni-based T-700 Tribaloy alloys in different ratios and fabricated via spark plasma sintering (SPS) process. The phase transformation behavior of the mixed powders of T-800 and T-700 is investigated with differential scanning calorimetry (DSC) analysis. The microstructures of the SPS specimens and solidified DSC samples of the created HEAs are studied using SEM and XRD, showing that they consist of fcc Co, Mo, and Ni solid solution with minor hcp Co solid solution, various Laves phase, mainly Co3Mo2Si, CoMoSi, Ni3Mo2Si, Mo2Si, and CrSi2, and complex intermetallic compounds. The hardness and dry-sliding wear resistance of the created SPS HEAs are evaluated and compared with the initial alloys (T-800 and T-700). It is shown that the hardness and wear resistance of T-800 are much higher than that of T-700, which is attributed to the excellent properties of element Co; the created HEAs exhibit better hardness and wear performance than T-700 but worse than T-800. The HEA having an equal mixture ratio of T-800 and T-700, with the largest configurational entropy of 1.58R, performs the best in wear resistance among the HEAs.

Similar content being viewed by others

References

J.R. Davis, Introduction to Cobalt and Cobalt Alloys, Nickel, Cobalt, and Their Alloys. ASM International, Materials Park, 2000, p 343–370

R. Liu and M.X. Yao, High-Temperature Wear/Corrosion Resistant Stellite Alloys and Tribaloy Alloys, CRC Handbook on Aerospace and Aeronautical Materials. CRC Press Taylor & Francis, 2012, p 151–235

D. Raghu and J.B. Wu, Recent Development in Wear and Corrosion-Resistant Alloys, Mater. Perform., 1997, 36(11), p 27–36.

C.B. Cameron, R.A. Hoffman, and R.W. Poskitt, Tribaloy Intermetallic Alloy Compositions—New Materials or Additives for Wear Resistant Applications, Prog. Powd. Metall., 1975, 31, p 41–51.

W. Xu, R. Liu, P.C. Patnaik, M.X. Yao, and X.J. Wu, Mechanical and Tribological Properties of Newly Developed Tribaloy Alloys, Mater. Sci. Eng. A, 2007, 452–453, p 427–436.

C.B. Cameron and D.P. Ferriss, Tribaloy Intermetallic Materials: New Wear- and Corrosion-Resistant Alloys, Anti-Corr. Methods Mater., 1975, 22(4), p 5–8.

S.E. Mason and R.D. Rawlings, Structure and Hardness of Ni-Mo-Cr-Si Wear and Corrosion Resistant Alloys, Mater. Sci. Technol., 1989, 5(2), p 180–185.

C.J. Chen, M. Zhang, and S.Q. Wang, The Effects of Heat Treatment on Microstructure and Mechanical Properties of Tribaloy 400 Coatings Deposited by Laser Cladding, J. Mater. Eng. Perform., 2018, 27(12), p 6339–6348.

X.Y. Wu, X.Z. Zhang, R. Liu, and M.X. Yao, Microstructure and Performance Characterization of a Novel Cobalt High-Entropy Alloy, Metall. Mater. Trans. A, 2021, 52, p 4066–4089.

M.C. Gao, P.K. Liaw, J.W. Yeh, and Y. Zhang, Phase Formation Rules, High-Entropy Alloys: Fundamentals and Applications. Springer, Heidelberg, 2016, p 21–49

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218.

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46(12), p 2817–2829.

A.W. Weeber, Application of the Miedema Model to Formation Enthalpies and crystallization Temperatures of Amorphous Alloys, J. Phys. F: Met. Phys., 1987, 17(4), p 809–813.

F. Stein and A. Leineweber, Laves Phases: A Review of Their Functional and Structural Applications and an Improved Fundamental Understanding of Stability and Properties, J. Mater. Sci., 2021, 56, p 5321–5427.

W. Betteridge, Constitution and Metallography of Cobalt Alloys, Cobalt and Its Alloys. Halsted Press, Chichester, 1982, p 41–59

Acknowledgment

The authors are grateful for financial support from the Natural Science & Engineering Research Council of Canada (NSERC), in-kind support from National Research Council Canada (NRC), and both financial and in-kind support of Kennametal Stellite Inc.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, X., Liu, R., Zhang, X. et al. Microstructure and Wear Performance of High-Entropy Tribaloy Alloys. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08349-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08349-8