Abstract

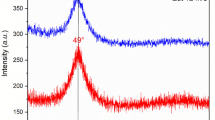

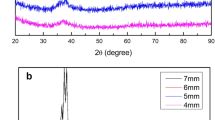

For the balanced consumption of pricey rare-earth element yttrium (Y) and improved pitting corrosion resistance of alloys, Y was partially substituted by cerium (Ce) in a novel kind of quinary AlNiCoYCex high-entropy metallic glass (HE-MG) via vacuum arc melting and rapid solidification. The microstructure, thermal stability and micro-hardness of Al30Ni30Co8Y32-xCex (x = 1, 2, 3, 4, 5, and 8 at%) high-entropy metallic glass ribbons (hereafter referred to as HE-MG ribbons) have been systematically investigated. In addition, the electrochemical corrosion properties of these amorphous ribbons with different Ce content in 3.5 wt.% NaCl solution have been determined by potentiodynamic polarization and electrochemical impedance spectroscopy. After 100 h immersion in corrosive media, scanning electron microscope images of the corroded ribbons were also characterized. The results indicated that these ribbon samples could remain in an amorphous state, and the that micro-hardness was more than 495 HV0.1. With increasing Ce content, the thermal stability started to gradually increase and then decrease. Furthermore, Ce is responsible for an improvement in anticorrosion performance compared with the Ce-free alloys. Ce-containing HE-MG ribbons showed a passive region in the electrochemical reaction, and ribbons with 3 at% Ce exhibited the most corrosion resistance by virtue of the smallest Icorr and Ipass.

Similar content being viewed by others

References

S.H. Chen, X.J. Mi, G.J. Huang, and Y.F. Li, Mater. Res. Express 6, 016518. https://doi.org/10.1088/2053-1591/aae1e6 (2019).

S. Chi, J. Park, and M. Shon, J. Ind. Eng. Chem. 26, 384. https://doi.org/10.1016/j.jiec.2014.12.013 (2015).

T.Y. Zhang, W. Liu, B.J. Dong, R. Mao, Y.P. Sun, and L.J. Chen, J. Phys. Chem. Solids. 163, 110584. https://doi.org/10.1016/j.jpcs.2022.110584 (2022).

F.J. Antunes, V.R.D.S. de Sá Brito, I.N. Bastos, and H.R.M. Costa, Appl. Adhes. Sci. 1, 3. https://doi.org/10.1186/2196-4351-1-3 (2013).

J. Gao, W. Hu, R. Wang, and X. Li, Polym. Test. 100, 107259. https://doi.org/10.1016/j.polymertesting.2021.107259 (2021).

S.Y. Zhang, Y.Y. Gao, Z.B. Zhang, T. Gu, X.B. Liang, and L. Wang, Chin. J. Rare Met. 45, 717. (2021).

S.Y. Zhang, Z.B. Zhang, Y.Y. Gao, X.B. Liang, and L.Z. Wang, Rare Met. Mater. Eng. 50, 2215. (2021).

C. Zhang, D. Ouyang, S. Pauly, and L. Liu, Mater. Sci. Eng. R. 145, 100625. https://doi.org/10.1016/j.mser.2021.100625 (2021).

Y. Qiu, M.A. Gibson, H.L. Fraser, and N. Birbilis, Mater. Sci. Technol. 31, 1235. https://doi.org/10.1179/1743284715Y.0000000026 (2015).

H. Sahin, and H. Zengin, Int. J. Metalcast. https://doi.org/10.1007/s40962-021-00744-y (2022).

J. Cheng, Y. Feng, C. Yan, X. Hu, R. Li, and X. Liang, JOM. 72, 745. https://doi.org/10.1007/s11837-019-03966-y (2020).

A. Aditya, H. Felix Wu, H. Arora, and S. Mukherjee, JOM 69, 2150. https://doi.org/10.1007/s11837-017-2384-9 (2017).

S.Y. Zhang, Z.B. Zhang, P.F. He, Z.F. Hu, Z.Y. Jing, Y.Y. Gao, and X.B. Liang, J. Non-Cryst. Solids. 576, 121268. https://doi.org/10.1016/j.jnoncrysol.2021.121268 (2022).

S.Y. Zhang, Z.B. Zhang, X. Wang, Y.Y. Gao, X.B. Liang, and L. Wang, Rare Met. Mater. Eng. 50, 4587. (2021).

Q. Ren, and L.F. Zhang, Metall. Mater. Trans. B. 51, 589. https://doi.org/10.1007/s11663-020-01779-y (2020).

L. Yang, M. Bi, J. Jiang, X. Ding, M. Zhu, W. Li, Z. Lv, and Z. Song, J. Magn. Magn. Mater. 432, 181. https://doi.org/10.1016/j.jmmm.2017.01.094 (2017).

L.M. Zhang, S.D. Zhang, A.L. Ma, A.J. Umoh, H.X. Hu, Y.G. Zheng, B.J. Yang, and J.Q. Wang, J. Mater. Sci. Technol. 35, 1378. https://doi.org/10.1016/j.jmst.2019.03.014 (2019).

X. Li, W. Xia, H. Yan, J. Chen, and X. Li, Corros. Eng. Sci. Technol. 55, 381. https://doi.org/10.1080/1478422X.2020.1735716 (2020).

K. Liu, C. Chen, J. He, B. Liu, B. Ma, H. Xue, B. Yang, S. Wang, and H. Liu, Mater. Res. Exp. 8, 096518. https://doi.org/10.1088/2053-1591/ac19e7 (2021).

L.F.S. Baroni, R. Silva, G.S. Vacchi, V.L. Sordi, and C.A.D. Rovere, Mater. Today Commun. 25, 101649. https://doi.org/10.1016/j.mtcomm.2020.101649 (2020).

W. Tian, M. Hu, X. Chen, H. Zhou, Y. Sun, Q. Lu, and M. Wan, Mater. Res. Exp. 7, 036532. https://doi.org/10.1088/2053-1591/ab80aa (2020).

L.C. Xie, C.Q. Peng, R.C. Wang, Z.Y. Cai, W.S. Liu, and R.L. Ma, Rare Met. Mater. Eng. 44, 1006. (2015).

X. Yang, and Y. Zhang, Mater. Chem. Phys. 132, 233. https://doi.org/10.1016/j.matchemphys.2011.11.021 (2012).

S. Guo, Mater. Sci. Technol. 31, 1223. https://doi.org/10.1179/1743284715Y.000000001 (2015).

T. Yu, H. Wang, K. Han, and B. Zhang, Vacuum 199, 110928. https://doi.org/10.1016/j.vacuum.2022.110928 (2022).

S. Guo, and C.T. Liu, Prog. Nat. Sci.: Mater. Int. 21, 433. https://doi.org/10.1016/S1002-0071(12)60080-X (2011).

P.K. Rai, B. Satapathy, K. Sarkar, P. Bijalwan, M. Dutta, A. Banerjee, and K. Mondal, J. Non-Cryst. Solids 532, 119883. https://doi.org/10.1016/j.jnoncrysol.2019.119883 (2020).

M. Malekan, R. Rashidi, and S.G. Shabestari, Vacuum 174, 109223. https://doi.org/10.1016/j.vacuum.2020.109223 (2020).

M. Mansouri, A. Simchi, N. Varahram, and E.S. Park, Mater. Sci. Eng. A 604, 92. https://doi.org/10.1016/j.msea.2014.03.012 (2014).

S.A. Uporov, N.S. Uporova, V.A. Bykov, T.V. Kulikova, and S.V. Pryanichnikov, J. Alloys Compd. 586, S310. https://doi.org/10.1016/j.jallcom.2012.09.093 (2014).

B. Rusanov, V. Sidorov, P. Svec, P. Svec, D. Janickovic, A. Moroz, L. Son, and O. Ushakova, J. Alloys Compd. 787, 448. https://doi.org/10.1016/j.jallcom.2019.02.058 (2019).

J. Guo, X. Hu, J. Liu, T. Feng, E.Y. Yoon, and H.S. Kim, Arch. Metall. Mater. 60, 1543. https://doi.org/10.1515/amm-2015-0169 (2015).

M. Yang, X.J. Liu, Y. Wu, H. Wang, S.H. Jiang, X.Z. Wang, and Z.P. Lu, SCI SIN-PHYS MECH AS. 50, 21. (2020).

P. Gong, K.R. Li, D.L. Wang, M. Zhang, L. Deng, J.S. Jin, and X.Y. Wang, Chin. Sci. Bull. 67, 1103. https://doi.org/10.1360/TB-2021-1124 (2022).

K. Chong, Z.B. Zhang, Y. Zou, and X.B. Liang, Mater. Rep. 35, 17019. https://doi.org/10.11896/cldb.20120197 (2021).

Z.B. Zhang, S.Y. Zhang, Y.X. Chen, Y.Y. Gao, and X.B. Liang, China Surf. Eng. 34, 76. https://doi.org/10.11933/j.issn.1007-9289.20210512001 (2021).

W. Dong, X. Wu, and M. Yan, Met. Mater. Int. 27, 4286. https://doi.org/10.1007/s12540-020-00720-x (2021).

D.B. Miracle, and O.N. Senkov, Acta Mater. 122, 448. https://doi.org/10.1016/j.actamat.2016.08.081 (2017).

C. Chattopadhyay, and B.S. Murty, Scr. Mater. 116, 7. https://doi.org/10.1016/j.scriptamat.2016.01.022 (2016).

J. Cheng, B. Sun, Y. Ge, X. Hu, L. Zhang, X. Liang, and X. Zhang, Surf. Coat. Technol. 402, 126321. https://doi.org/10.1016/j.surfcoat.2020.126321 (2020).

E. Karakose, A.M. Ibrahim, and M. Keskin, J. Inorg. Organomet. Polym. Mater. 28, 2645. https://doi.org/10.1007/s10904-018-0929-1 (2018).

S. Zhao, H. Wang, L. Xiao, N. Guo, D. Zhao, K. Yao, and N. Chen, Phy. E. 94, 100. https://doi.org/10.1016/j.physe.2017.07.021 (2017).

R.K. Mishra, and R.R. Shahi, J. Magn. Magn. Mater. 516, 167342. https://doi.org/10.1016/j.jmmm.2020.167342 (2020).

M. Wu, R.C. Setiawan, and D.Y. Li, Wear 492–493, 204231. https://doi.org/10.1016/j.wear.2021.204231 (2022).

P. Cheng, Y. Chen, and W. Ding, Mater. Sci. Forum. 904, 80. https://doi.org/10.4028/www.scientific.net/MSF.904.80 (2017).

J. Henao, A. Concustell, I.G. Cano, S. Dosta, N. Cinca, J.M. Guilemany, and T. Suhonen, Mater. Des. 94, 253. https://doi.org/10.1016/j.matdes.2016.01.040 (2016).

O. Mohamed, M. Hassan, M. Egilmez, W. Abuzaid, T. Ibrahim, and M. Khamis, Mater. Today Commun. 30, 103015. https://doi.org/10.1016/j.mtcomm.2021.103015 (2022).

W. Li, and D.J. Kong, Anti-Corros. Methods Mater. 69, 171. https://doi.org/10.1108/ACMM-11-2021-2568 (2022).

X.B. Liang, J.W. Fan, Z.B. Zhang, and Y.X. Chen, Acta. Metall. Sinica. 54, 1193. https://doi.org/10.11900/0412.1961.2017.00491 (2018).

X. Qi, B. Sun, X.M. Chen, and R.G. Song, J. Wuhan Univ. Technol. Mater. Sci. 35, 986. https://doi.org/10.1007/s11595-020-2346-x (2020).

P.C. Cui, Z.J. Bao, Y. Liu, F. Zhou, Z.H. Lai, Y. Zhou, and J.C. Zhu, Corros. Sci. 201, 110276. https://doi.org/10.1016/j.corsci.2022.110276 (2022).

X.Y. Gu, Y.X. Zhuang, and D. Huang, Intermetallics 147, 107600. https://doi.org/10.1016/j.intermet.2022.107600 (2022).

P. Li, X. Huang, and D. Kong, Anti-Corros. Methods Mater. 68, 95. https://doi.org/10.1108/ACMM-08-2020-2357 (2021).

Z. Dan, K. Takenaka, Y. Zhang, S. Unami, A. Takeuchi, N. Hara, A. Makino, and J. Non-Cryst, Solids 402, 36. https://doi.org/10.1016/j.jnoncrysol.2014.05.007 (2014).

Y. Ge, J. Cheng, C. Yan, B. Zhang, S. Zhu, L. Xue, S. Hong, Y. Wu, Z. Zhang, X. Liang, and X. Zhang, Intermetallics 143, 107473. https://doi.org/10.1016/j.intermet.2022.107473 (2022).

Z. Xu, H. Zhang, X. Du, Y. He, H. Luo, G. Song, L. Mao, T. Zhou, and L. Wang, Corros. Sci. 177, 108954. https://doi.org/10.1016/j.corsci.2020.108954 (2020).

Y. Wang, J.S. Jin, M. Zhang, F.M. Liu, X.Y. Wang, P. Gong, and X.F. Tang, J. Alloys Compd. 891, 161822. https://doi.org/10.1016/j.jallcom.2021.161822 (2022).

Y. Liu, K. Zhang, J. Zou, P. Yan, X. Zhang, and L. Song, J. Magnes. Alloys 9, 216. https://doi.org/10.1016/j.jma.2020.02.019 (2021).

Y. Tang, X. Shen, Y. Qiao, L. Yang, J. Chen, D. Lu, and Z. Zhang, J. Mater. Eng. Perform. 30, 5506. https://doi.org/10.1007/s11665-021-05909-8 (2021).

Acknowledgements

The authors are sincerely grateful to eceshi (www.eceshi.com) for the TEM analysis and characterization, and to Shiyanjia Lab (www.shiyanjia.com) for the XRD and SEM characterization. The authors also gratefully appreciate that Prof. Shen Baolong from Southeast University and Dr. Chen Changjiu from China University of Mining and Technology have provided help on using the experiment facilities and the alloy ribbon preparation site for our study. Specifically, the first author, Zhang Shuyan, appreciates the scientific insight and help from Dr. He Pengfei from the Defense Innovation Institute and Dr. Xue Lin from Hohai University during the revision process of our manuscript.

Funding

This project was supported by the National Key Research and Development Program of China (Grant No. 2018YFC1902400) and National Natural Science Foundation of China (Grant No. 51975582).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, S., Zhang, Z., Li, X. et al. An Experimental Study on the Role of Partial Replacement of Y with Ce in a Novel Quinary AlNiCoYCex High Entropy Metallic Glasses. JOM 74, 4215–4225 (2022). https://doi.org/10.1007/s11837-022-05426-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05426-6