Abstract

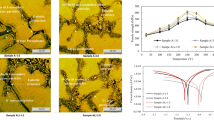

Cast Al-Cu-Mg-Mn alloy, prepared by differential pressure casting method, was quenched at 530 °C and aged at 170 °C. The effect of aging time on the corrosion resistance of the Al alloy was investigated in 3.5 wt.% NaCl solution by potentiodynamic polarization and electrochemical impedance spectroscopy tests. The results indicated that the aging time had great influence on the distribution of the Al2Cu phase. A small amount of fine second phase had precipitated along grain boundaries to strengthen the alloy when the aging time was 6 h. Extended aging time led to the rapid growth of the second phase. Pitting corrosion occurred at the interface between the Al2Cu phase and α-Al matrix in 3.5wt.% NaCl solution. The Al2Cu phase with a small size easily fell off to form corrosion pits during the corrosion process, leading to more serious pitting corrosion. However, a network-like Al2Cu phase prevented its falling off, improving pitting corrosion resistance.

Similar content being viewed by others

References

T. Dursun and C. Soutis, Mater. Des. https://doi.org/10.1016/j.matdes.2013.12.002 (2014).

S.G. Pantelakis, A.N. Chamos, and A.T. Kermanidis, Theor. Appl. Fract. Mech. https://doi.org/10.1016/j.tafmec.2011.12.006 (2012).

J. Liu and M. Kulak, Mater. Sci. Forum. https://doi.org/10.4028/www.scientific.net/MSF.331-337.127 (2000).

Q. Zheng, C. Yang, S. Wang, A. Yu, H. Chen, and Y. He, Mater. Res. Innovations. https://doi.org/10.1179/1432891714z.000000000377 (2014).

J.B. Zhang, Y.A. Zhang, B.H. Zhu, R.Q. Liu, F. Wang, and Q.M. Liang, Mater. Des. https://doi.org/10.1016/j.matdes.2013.01.044 (2013).

Y. Meng, Z. Zhao, and J. Cui, Trans. Nonferrous Met. Soc. China. https://doi.org/10.1016/s1003-6326(13)62673-4 (2013).

X.Y. Liu, Q.L. Pan, X.L. Zhang, S.X. Liang, F. Gao, L.Y. Zheng, and M.X. Li, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2014.01.090 (2014).

S. Bai, X. Zhou, Z. Liu, P. Xia, M. Liu, and S. Zeng, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2014.05.065 (2014).

Y.C. Lin, Y. Ding, M.S. Chen, and J. Deng, Mater. Des. https://doi.org/10.1016/j.matdes.2013.05.036 (2013).

Z. Szklarska-Smialowska, Corros. Sci. https://doi.org/10.1016/s0010-938x(99)00012-8 (1999).

J. Geng, Y. Li, G. Liu, H. Xiao, T. Hong, J. Huang, M. Wang, D. Chen, and H. Wang, Mater. Charact. https://doi.org/10.1016/j.matchar.2020.110571 (2020).

S. Gollapudi, Corros. Sci. https://doi.org/10.1016/j.corsci.2012.04.040 (2012).

X. Zhang, X. Zhou, T. Hashimoto, J. Lindsay, O. Ciuca, C. Luo, Z. Sun, X. Zhang, and Z. Tang, Corros. Sci. https://doi.org/10.1016/j.corsci.2016.12.005 (2017).

J.F. Li, Z.Q. Zheng, S.C. Li, W.J. Chen, W.D. Ren, and X.S. Zhao, Corros. Sci. https://doi.org/10.1016/j.corsci.2006.12.002 (2007).

A.S. Román, C.M. Méndez, C.A. Gervasi, R.B. Rebak, and A.E. Ares, J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-020-05344-1 (2020).

W.R. Osório, J.E. Spinelli, I.L. Ferreira, and A. Garcia, Electrochim. Acta. https://doi.org/10.1016/j.electacta.2006.10.004 (2007).

J. Wang, Z. Liu, S. Bai, J. Cao, J. Zhao, and D. Zeng, J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-020-05072-6 (2020).

D.Y. Liu, J.F. Li, Y.C. Lin, P.C. Ma, Y.L. Chen, X.H. Zhang and R.F. Zhang, Acta Metall. Sin. (Engl. Lett.). (2020). https://doi.org/10.1007/s40195-020-01023-1

J. Huang, S. Feng, S. Li, C. Wu, and J. Chen, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.158588 (2021).

J.V.D. Araujo, M.X. Milagre, R.O. Ferreira, C.D.C. Machado, A.D.S. Bugarin, I.F. Machado, and I. Costa, Mater. Corros. https://doi.org/10.1002/maco.202011839 (2020).

J. Xu, Y. Deng, and J. Chen, Materials. https://doi.org/10.3390/ma13112628 (2020).

X.Y. Liu, Z.P. Wang, B.G. Fu, L. Long, X.L. Zhang, and H.X. Cui, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2016.05.247 (2016).

S.K. Kairy, B. Rouxel, J. Dumbre, J. Lamb, T.J. Langan, T. Dorin, and N. Birbilis, Corros. Sci. https://doi.org/10.1016/j.corsci.2019.108095 (2019).

J. Fu and K. Cui, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2021.162903 (2022).

G. Chen, T. Zhou, B. Wang, H. Liu, and F. Han, Trans. Nonferrous Met. Soc. China. https://doi.org/10.1016/S1003-6326(16)64086-4 (2016).

Y. Li, Z. Liu, S. Bai, L. Lin, and L. Gao, J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-011-0040-z (2012).

Y.C. Lin, G. Liu, M.S. Chen, J.L. Zhang, Z.G. Chen, Y.Q. Jiang, and J. Li, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2015.11.173 (2016).

X.Y. Liu, M.J. Li, F. Gao, S.X. Liang, X.L. Zhang, and H.X. Cui, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2015.03.174 (2015).

K.S. Ghosh, M. Hilal, and S. Bose, Trans. Nonferrous Met. Soc. China. https://doi.org/10.1016/s1003-6326(13)62856-3 (2013).

Z. Wang, P. Chen, H. Li, B. Fang, R. Song, and Z. Zheng, Corros. Sci. https://doi.org/10.1016/j.corsci.2016.11.013 (2017).

W.N. Shi, H.F. Zhou and X.F. Zhang, Acta Metall. Sin. (Engl. Lett.). (2020). https://doi.org/10.1007/s40195-020-01060-w

V. Guillaumin and G. Mankowski, Corros. Sci. https://doi.org/10.1016/j.corsci.2014.03.001 (1998).

J.A. Moreto, C.E.B. Marino, W.W. Bose Filho, L.A. Rocha and J.C.S. Fernandes, Corros. Sci. (2014). https://doi.org/10.1016/j.corsci.2014.03.001

F. Mansfeld, S. Lin, S. Kim, and H. Shih, J. Electrochem. Soc. https://doi.org/10.1149/1.2086442 (1990).

S. Sivakumar, S.K. Thimmappa, and B.R. Golla, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2018.07.117 (2018).

W.G. Zhao, J.G. Wang, H.L. Zhao, J.Q. Hou, and Q.C. Jiang, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2008.12.095 (2009).

X. Lei, V.L. Nuam, Y. Yuan, Y. Bai, W. Yao, and N. Wang, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2021.159765 (2021).

S.C. Ferreira, L.A. Rocha, E. Ariza, P.D. Sequeira, Y. Watanabe, and J.C.S. Fernandes, Corros. Sci. https://doi.org/10.1016/j.corsci.2011.02.010 (2011).

H. Shi, E.H. Han, and F. Liu, Corros. Sci. https://doi.org/10.1016/j.corsci.2011.03.012 (2011).

R. Arrabal, B. Mingo, A. Pardo, M. Mohedano, E. Matykina, and I. Rodríguez, Corros. Sci. https://doi.org/10.1016/j.corsci.2013.04.023 (2013).

B. Wang, J. Liu, M. Yin, Y. Xiao, X.H. Wang, and J.X. He, Mater. Corros. https://doi.org/10.1002/maco.201408211 (2016).

W. Tian, M. Hu, X. Chen, H. Zhou, Y. Sun, Q. Lu, and M. Wan, Mater. Res. Express. https://doi.org/10.1088/2053-1591/ab80aa (2020).

C. Li, Q. Pan, Y. Shi, Y. Wang, and B. Li, Mater. Des. https://doi.org/10.1016/j.matdes.2013.10.018 (2014).

W.R. Osório, L.C. Peixoto, L.R. Garcia and A. Garcia, Acta Metall. Sin. (Engl. Lett.). (2009). https://doi.org/10.1016/s1006-7191(08)60095-2

Z. Liu, P.H. Chong, P. Skeldon, P.A. Hilton, J.T. Spencer, and B. Quayle, Surf. Coat. Technol. https://doi.org/10.1016/j.surfcoat.2005.07.108 (2006).

H. Zhou, Int. J. Electrochem. Sci. (2017). https://doi.org/10.20964/2017.10.32

Y.A. Meyer, R.S. Bonatti, A.D. Bortolozo, and W.R. Osório, J. Solid State Electrochem. https://doi.org/10.1007/s10008-020-04890-x (2021).

M.F. Wang, D.H. Xiao, B.R. Sun, and W.S. Liu, J. Alloys Compd. https://doi.org/10.1016/j.jallcom.2018.10.290 (2019).

J.V.D. Araujo, R.M.P. da Silva, U. Donatus, C.D.C. Machado and I. Costa, Mater. Res. (Sao Carlos, Braz.). (2020). https://doi.org/10.1590/1980-5373-mr-2020-0161

J. Araujo, R. Silva, M. Milagre, C. Machado and I. Costa, Quim. Nova. (2020). https://doi.org/10.21577/0100-4042.20170598

J.L. Lv and H.Y. Luo, Surf. Coat. Technol. https://doi.org/10.1016/j.surfcoat.2013.07.071 (2013).

Acknowledgements

The authors gratefully acknowledge financial support from the Education Department of Yunnan Province Fund, China (grant no. KKPS201951007).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Luo, B., Lu, K., Zhang, F. et al. Effect of Aging Time on the Corrosion Resistance of the As-cast Al-Cu-Mg-Mn Alloy. JOM 74, 3616–3624 (2022). https://doi.org/10.1007/s11837-022-05399-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05399-6