Abstract

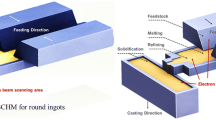

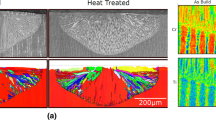

A multi-physics model has been developed to investigate the molybdenum and nickel distribution in large-scale Ti-0.3 wt.% Mo-0.8 wt.% Ni slab ingots obtained by electron beam cold hearth melting. Numerical methods are pivotal in revealing the distribution trends of molybdenum and nickel in slab ingot in different casting conditions. The distribution of molybdenum slightly changed between 0.28 and 0.32 wt.% in the solidified ingot. However, the sharp change in the nickel distribution (between 0.73 and 1.53 wt.%) was caused by the fluid velocity decrease along the flow direction, resulting from a weakened vortexing effect. Additionally, the increase of the casting speed or pouring temperature led to a deeper molten pool and evident vortexing effect. A potential relationship indicates the decrease of nickel segregation degree at higher pouring temperatures, or the casting speed decrease within the research scope.

Similar content being viewed by others

Abbreviations

- \(A_{{{\text{mushy}}}}\) :

-

Mushy zone constant

- \(A_{r}\) :

-

Pre-exponential factor (consistent units)

- \(a_{p}\) :

-

Cell matrix coefficient

- \(p\) :

-

Statics pressure, Pascal

- \(B_{T}\) :

-

Thermal expansion coefficient, 1/K

- \(C_{c,i}\) :

-

Solutal expansion coefficient, 1/wt.%

- \(\beta\) :

-

Liquid fraction

- \(C_{p}\) :

-

Specific heat, J/kg K

- \(D_{i,m,liq}\) :

-

Mass diffusion coefficient for species in the mixture, m2/s

- \(T\) :

-

Temperature, K

- \(\vec{Q}_{r}\) :

-

Source term

- \(\vec{g}\) :

-

Acceleration due to gravity, m/s2

- \(H\) :

-

Enthalpy, J/kg

- \(h\) :

-

Sensible enthalpy, J/kg

- \(h_{{{\text{ref}}}}\) :

-

Reference enthalpy, J/kg

- \({\Delta }H_{f}\) :

-

Pure solvent melting heat, J/kg

- \(k\) :

-

Thermal conductivity, K/m K

- \(K_{i}\) :

-

The partition coefficient of solute i

- \(K_{f,i}\) :

-

Forward rate constant for reaction

- \(L_{C}\) :

-

Latent heat of the material, J/kg

- \(Y_{{i,{\text{sol}}}}\) :

-

Locally averaged concentration of solute element i in solid phase, wt%

- \(m_{i}\) :

-

The slope of the liquidus surface with respect to Yi

- \(n\) :

-

Iteration number

- \(N_{t}\) :

-

Number of species

- \(\overline{{\overline{\tau }}}\) :

-

Stress tensor, N/m2

- \(\rho\) :

-

Density, kg/m3

- \(\sum\nolimits_{i} {}\) :

-

Sum based on solute element i

- \(T_{{{\text{ref}}}}\) :

-

Reference temperature, K

- \(T_{c}\) :

-

Cell temperature, K

- \(T^{*}\) :

-

Interface temperature, K

- \(T_{{{\text{melt}}}}\) :

-

Melting temperature, K

- \(R_{i}\) :

-

Reaction rate, kg/m2 s

- \(Y_{i}\) :

-

The mass fraction of solute i

- \(\Delta t\) :

-

Time step

- \( \overrightarrow {v} \) :

-

Cell velocity, m/s

- \( \overrightarrow {v}_{p}\) :

-

Pull velocity, m/s

- \(\vec{v}_{{{\text{liq}}}}\) :

-

Velocity of the liquid, m/s

- \(Y_{0}\) :

-

The initial mass fraction of solute i, wt%

- \(\lambda\) :

-

Relaxation factor with a default value, 0.9

- \(L\) :

-

Characteristic length, m

- \(V_{c}\) :

-

Cell volume, m3

- \(Y_{{i,{\text{liq}}}}\) :

-

Locally averaged concentration of solute element i in liquid phase, wt

References

S.W. Ji, J.L. Duan, L. Yao, M.M. Daan, L.C. Steve, and F. Dan, INT J. Heat Mass Trans. 119, 271. (2018).

G. Ares, M. Paranjayee, G. Diego, Z. Nicola, and B. Paul, Defect and Diffus. Forum 395, 419. (2018).

H.R. Harker, Vacuum 41, 2154. (1990).

A. Mitchell, Mater. Sci. Eng. A 263, 217. (1999).

Q.L. Liu, Y.H. Jiang, and X.M. Li, Mater. Sci. Eng. 34, 1649. (2018).

M. Reza Aboutalebi, M. Hasan, and R.I.L. Guthrie, Metal Mater. Trans. B. 26, 731. (1995).

X. Zhao, C. Reilly, L. Yao, D.M. Maijer, S.L. Cockcroft, and J. Zhu, Appl. Math. Model. 38, 3607. (2014).

Q.L. Liu, Y.H. Jiang, and X.M. Li, J. Mater. Res. 32, 1. (2017).

Q.L. Liu, Y.H. Jiang, and X.M. Li, Vacuum 141, 1. (2017).

L. Gao, X.M. Li, and H.G. Huang, INT J. Heat Mass Trans. 139, 1. (2019).

X. L. Yuan, Editorial board of China aeronautical materials manual, China, pp. 498 (2002).

H.G. Huang, Z.Y. Cao, Z.M. Li, Y.Q. Zhang, Y.M. Shi, and G.H. Bao, Spec. Cast. Nonferrous Alloys. 36, 90. (2016).

J. Zhang, Y.Q. Wang, R.Y. Hu, R. Cao, and N. Li, World Nonferrous Met. 23, 127. (2020).

H.F. Shen, and C. Beckermann, Metal. Mater. Trans. B. 33, 69. (2002).

K.Z. Vutova and E.G. Koleva, Int. Rev. Mech. Eng. 5, 257. (2009).

L. Gao, H.G. Huang, Y.Q. Zhang, H.M. Zhang, Z. Shi, and Y.H. Jiang, JOM 70, 2934. (2018).

H. Chen, M. Long, D. Chen, T. Liu, and H. Duan, INT J. Heat Mass Trans. 126, 843. (2018).

W.D. Bennon, and F.P. Incropera, INT J Heat Mass Trans. 30, 2161. (1987).

A.D. Brent, V.R. Voller, and K.J. Reid, Numer. Heat Trans. 13, 297. (1988).

J. Li, M. Wu, A. Ludwig, and A. Kharicha, INT J Heat Mass Trans. 72, 668. (2014).

B.B. Peng, Numerical simulation of solidification process during electron beam cold hearth melting for TA10 alloy ingot, Masters thesis, Kunming University of Science and Technology (2018).

Acknowledgements

This work was supported by Major Science and Technology Projects of Yunnan Science and Technology Plan (No. 202002AB080001) and Science and Technology Major Project of Yunnan Province (No. 202202AG50007).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Z., Li, X., Zhou, R. et al. Numerical Simulation of Molybdenum and Nickel Distribution in Large-Scale Slab Ingots of Ti-0.3 wt.% Mo-0.8 wt.% Ni Alloys During Electron Beam Cold Hearth Melting. JOM 74, 3811–3820 (2022). https://doi.org/10.1007/s11837-022-05396-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05396-9