Abstract

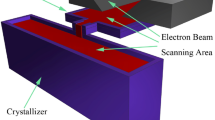

In the present paper, a three-dimensional thermal-fluid multi-physical model has been established to investigate the effect of energy consumption operations on the evolutionary tendency of the solid–liquid interface for large-scale Ti-6 wt.%Al-4 wt.%V (TC4) round (Φ260 mm and Φ620 mm)/slab (1050 mm × 220 mm) ingots produced by electron beam cold hearth melting. The results qualitatively revealed the evolutionary tendency of the solid–liquid interface in different casting conditions, indicating that the solid–liquid interface with a gentle casting speed at a low pouring temperature will generate symmetric solid–liquid interfaces which were slightly affected by the modification of the pouring temperature. With an increasing energy input resulting from the rising casting speed, the deformation of the solid–liquid interface near the inlet was increased. As a result, the risk of breaking out and the formation of a non-uniform microstructure in the Φ620-mm round ingots and slab ingots was greatly increased.

Similar content being viewed by others

Abbreviations

- \( A_{\text{mush}} \) :

-

Mushy zone constant

- \( \beta \) :

-

Liquid fraction

- \( c_{p} \) :

-

Specific heat (J/kg K)

- \( g \) :

-

Acceleration due to gravity (m/s2)

- \( H \) :

-

Enthalpy (J/kg)

- \( h \) :

-

Sensible enthalpy (J/kg)

- \( h_{\text{ref}} \) :

-

Reference enthalpy (J/kg)

- \( \Delta H_{f} \) :

-

Pure solvent melting heat (J/kg)

- \( k \) :

-

Thermal conductivity (K/m K)

- L :

-

Characteristic length (m)

- P :

-

Pressure (Pa)

- \( \rho \) :

-

Density (kg/m3)

- \( \overline{\overline{\tau }} \) :

-

Stress tensor (N/m2)

- \( T_{\text{ref}} \) :

-

Reference temperature (K)

- \( T \) :

-

Temperature (K)

- t :

-

Time (s)

- \( \vec{v} \) :

-

Cell velocity (m/s)

- \( \vec{v}_{\text{p}} \) :

-

Pull velocity (m/s)

References

G. Itoh, R. Kaibyshev, E.M. Taleff, M. Tikhonova, and E. Sato, Defect Diffus. Forum 385, 419 (2018).

S. Ji, J. Duan, L. Yao, D.M. Maijer, S.L. Cockcroft, D. Fiore, and D.W. Tripp, Int. J. Heat Mass Transf. 119, 271 (2018).

J.R. Wood, JOM 54, 56 (2002).

Q. Liu, X. Li, and Y. Jiang, Mater. Sci. Technol. 34, 1649 (2018).

L. Gao, H. Huang, Y. Zhang, H. Zhang, Z. Shi, Y. Jiang, and R. Zhou, JOM 70, 2934 (2018).

L. Gao, X. Li, H. Huang, Y. Sui, H. Zhang, Z. Shi, K. Chattopadhyay, Y. Jiang, and R. Zhou, Int. J. Heat Mass Transf. 139, 764 (2019).

L. Gao, H. Huang, C. Kratzsch, H. Zhang, K. Chattopadhyay, Y. Jiang, and R. Zhou, Int. J. Heat Mass Transf. 147, 118976 (2020).

Z. Nie, R.A. Palghat, and Y. Hou, Int. J. Heat Mass Transf. 117, 1083 (2018).

Z. Nie, J. Deng, Y. Zhou, S. Wen, and Y. Hou, Int. Commun. Heat Mass Transf. 80, 148 (2017).

Z. Nie, Y. Hou, J. Deng, R.A. Palghat, S. Wen, and W. Ma, Appl. Therm. Eng. 125, 856 (2017).

Z. Nie, Y. Zhou, J. Deng, S. Wen, and Y. Hou, Int. J. Heat Mass Transf. 1142, 111 (2017).

A.C. Powell, Transport phenomena in electron beam melting and evaporation. PhD thesis, Massachusetts Institute of Technology, Boston, MA (1997).

L. Yao, D.M. Maijer, S.L. Cockcroft, D. Fiore, and D.W. Tripp, Int. J. Heat. Mass Transf. 126, 1123 (2018).

J. Ou, S.L. Cockcroft, D.M. Maijer, L. Yao, C. Reilly, and A. Akhtar, Int. J. Heat Mass Transf. 86, 221 (2015).

Q. Liu, X. Li, and Y. Jiang, Vacuum 141, 1 (2017).

Q. Liu, X. Li, and Y. Jiang, J. Mater. Res. 32, 3175 (2017).

X. Zhao, C. Reilly, L. Yao, D.M. Maijer, S.L. Cockcroft, and J. Zhu, Appl. Math. Model. 38, 3607 (2014).

A.D. Brent, V.R. Voller, and K.J. Reid, Numer. Heat Transf. 13, 297 (1988).

ANSYS Inc, ANSYS Fluent Theory Guide (Release 15.0, 2013). Accessed Nov 2013.

J. Li, M. Wu, A. Ludwig, and A. Kharicha, Int. J. Heat Mass Transf. 72, 668 (2014).

Z. Zhang, Modeling of al evaporation and Marangoni flow in electron beam button melting of Ti-6Al-4V. Masters thesis, The University of British Columbia (2013).

S. Ghosh, K. McReynolds, J.E. Guyer, and D. Banerjee, Model. Simul. Mater. Sci. Eng. 26, 075001 (2018).

Acknowledgements

This work was supported by China Postdoctoral Science Foundation No. 2018M633421, National Natural Science Foundation of China (Grant No. 51764052) and Innovative Research Team (in Science and Technology) in University of Yunnan Province.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, L., Huang, H., Jiang, Y. et al. Numerical Study on the Solid–Liquid Interface Evolution of Large-Scale Titanium Alloy Ingots During High Energy Consumption Electron Beam Cold Hearth Melting. JOM 72, 1953–1960 (2020). https://doi.org/10.1007/s11837-020-04089-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04089-5