Abstract

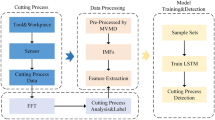

The use of chemical analysis to detect the carbon content of praseodymium–neodymium (Pr-Nd) alloys in industrial production has several disadvantages. To overcome those shortcomings, this article proposes a method for recognizing the carbon content of Pr-Nd alloys based on the Mel-frequency cepstrum coefficient (MFCC) of force signals and verifies the method through a self-developed microhole drilling experimental device. The reliability of the hardware and the rationality of the signal data are verified through the dynamic drilling force model and the cantilever beam structure equation. The model solution results show that the combination of MFCC and long short-term memory network can effectively recognize force signals, with an improved accuracy of 97.26%. Thus, the requirements of industrial production quality inspection are confirmed to be met. The model evaluation results show high performance indicators of the model; thus, the model is sufficiently robust. The method effectively controls the sampling time between 5 and 10 s, and the model substantially shortens the detection time for the carbon content of the Pr-Nd alloy to only 0.024–0.059 s. Thus, the requirements of an online real-time detection system are satisfied.

Similar content being viewed by others

References

Y. Wang, and M. Yue, Research progresses in preparation of 2:17 type Sm(CoCuFeZr)z permanent magnets with high magnetic properties. Chin. J. Rare Met. 43(11), 1210 (2019).

A. Hu, Q. Guo, S. Wang, L. Huang, Z. Wu, and J. Zhou, Theoretical investigation of 2.79 μm Er, Yb:GSGG mid-infrared laser. Infrared Laser Eng. 41(05), 1168 (2012).

H. Fang, G. Zhang, and L. Xia, Effects of rare earth on boriding strengthening property of iron-based powder metallurgy materials. China Surf. Eng. 33(05), 56 (2020).

T. Wu, L. Wang, H. He, H. Wang, H. Shen, Q. Liu, and Y. Shi, Research progress of Lu3Al5O12-based scintillation ceramics. Chin. J. Lumin. 42(07), 917 (2021).

W. Liu and Z. Lu, Application of pinacolborane in catalytic enantioselective hydroboration of ketones and imines. Chin. J. Org. Chem. 40(11), 3596 (2020).

M. Sun, J. Zhuang, H. Deng, Z. Chen, S. Si, and R. Zhang, Reviews on the study of aluminum alloys and aluminum matrix composites with high-temperature anti-creep behavior. Mater. Rep. 35(11), 11138 (2021).

Y. Yu, S. Wang, and W. Li, Effect of Ce solid solution doping on work function of LaB6 cathode material. Rare Met. Mater. Eng. 50(06), 2201 (2021).

L. Sun, L. Chen, Y. Wang, X. Zhang, and D. Xu, Research progress on mechanical and corrosion properties of Zn-Cu-Ti alloys. Mater. Rep. 35(03), 3152 (2021).

K. Mu, F. Zhang, C. Wang, W. Zhang, and L. Hu, Advance in studies on rare earth against plant disease. J. Chin. Rare Earth Soc. 01, 1 (2003).

Y. Wang, S. Liu, Q. Qin, H. Liu, L. Zhang, T. Wei, H. Li, and X. Liu, Praseodymium iridium oxide as a competitive electrocatalyst for oxygen evolution reaction in acid media. Sci. China (Materials) 64(09), 2193 (2021).

C. Chen, Y. Cao, S. Liu, J. Chen, and W. Jia, Review on the latest developments in modified vanadium-titanium-based SCR catalysts. Chin. J. Catal. 39(08), 1347. (2018).

A. Trench and J.P. Sykes, Rare earth permanent magnets and their place in the future economy. Engineering 6(02), 34 (2020).

Y. Chen, Research progress of preparation of rare earth metals by electrolysis in fluoride salt system. Chin. Rare Earths 35(02), 99 (2014).

L. Cheng, C. Chen, Y. Wen, Y. Peng, and G. Zheng, Determination of 17 rare earth impurities in high purity copper sulfate by ICP-MS. Chem. Reag. 42(10), 1196 (2020).

N. Yao, J. Chen, J. Li, and K. Hu, HCS-040 tube furnace infrared carbon and sulfur analyzer for determination of carbon and sulfur in rare earth metals. PTCA (Part B: Chemical Analysis) 38(05), 251 (2002).

F. Liu, B. Zeng, X. Wu, X. Chen, Y. Tu, and L. Cao, Research on drilling method for carbon content of PrNd alloy based on cutting force model. Chin. Rare Earths 43(02), 53 (2022).

J. Lin, Y. Chen, and Z. Xia, Electrical conductivity of fluoride melts in La-Nd cell electrolytes. Chin. Rare Earths 01, 27 (1998).

H.K. Lee, S.I. Chang, and E. Yoon, A flexible polymer tactile sensor: fabrication and modular expandability for large area deployment. J. Microelectromech. Syst. 15(6), 1681 (2006).

C. Roberto, O. Andrew, J. Dinesh, J. Lin, W. Yuan, M. Jitendra, E.H. Adelson, and L. Sergey, More than a feeling: learning to grasp and regrasp using vision and touch. IEEE Robot. Autom. Lett. 3(4), 3300 (2018).

B. Wu, I. Akinola, J. Varley, and P. Allen, MAT: Multi-fingered adaptive tactile grasping via deep reinforcement learning. (2019).

H. Zheng, F. Lu, M. Ji, M. Strese, Y. Özer, and E. Steinbach, Deep learning for surface material classification using haptic and visual information. IEEE Trans. Multimed. 18(12), 2407 (2016).

T. Miyagi and S. Katsura, Analysis and modeling based on cepstrum for haptic presentation considering frequency features of vibration in rubbing motion. IEEJ J. Ind. Appl. 4(2), 74 (2015).

T. Tsuji, K. Sato, and S. Sakaino, Contact feature recognition based on MFCC of force signals. IEEE Robot. Autom. Lett. PP(99), 1 (2021).

X. Wu, X. Chen, F. Liu, L. Wang, J. Li, and S. Chen, Research on classification of carbon content in Pr-Nd alloys based on MFCC and BP neural network. (2021). https://doi.org/10.1109/CAC53003.2021.9727226.

R. Jiao, K. Peng, and J. Dong, Remaining useful life prediction for a roller in a hot strip mill based on deep recurrent neural networks. IEEE/CAA J. Autom. Sin. 8(7), 10 (2021).

R. Wang, F. Yan, J. Lu, and W. Yang, COVID-19 trend forecasting by using dropout—LSTM model. J. Univ. Electron. Sci. Technol. China 50(03), 414 (2021).

Y. Wang, S. Li, S. Kang, J. Xie, and V.I. Mikulovich, Method of predicting remaining useful life of rolling bearing combining CNN and LSTM. J. Vib. Meas. Diagn. 41(03), 439 (2021).

S. Huang, C. Shao, J. Li, X. Zhang, and J. Qian, Vehicle trajectory reconstruction and anomaly detection using deep learning. J. Transp. Syst. Eng. Inf. Technol. 21(03), 47 (2021).

R. Li, T. Ma, X. Zhang, X. Hui, Y. Liu, and X. Yin, Short-term wind power prediction based on convolutional long-short-term memory neural networks. Acta Energ. Sol. Sin. 42(06), 304 (2021).

D. Wang and F. Jiao, Study on critical feed rate of delamination based on thrust force of chisel edge during CFRP drilling. J. Mech. Eng. 57(03), 255 (2021).

T. Zhao, J. Xiao, S. Fan, Z. Yang, and F. Yang, Study on chip shapes and drilling forces of low frequency vibration drilling of TC4 titanium alloy. China Mech. Eng. 31(19), 2276 (2020).

L. Zhang, Y. Wang, H. Zhao, S. Zhao, and Y. Hu, Computational simulation and experimental research on cutting force during high-speed bone drilling. J. Central South Univ. (Science and Technology) 49(09), 2191 (2018).

X. Tu, Q. Yang, P. Song, M. Zheng, J. Shen, and X. Yang, A credit scoring model based on logistic regression and RONSA. J. Sichuan Univ. (Engineering Science Edition) 46(06), 19 (2014).

F. Zhang, M. Ge, Z. Guo, C. Xie, Z. Yang, and Z. Song, Study of multiscale entropy model to evaluate the cognitive behavior of healthy elderly people based on resting state functional magnetic resonance imaging. Acta Phys. Sin. 69(10), 291 (2020).

W. Wang, Z. He, Z. Han, and Y. Qian, Landslides susceptibility assessment based on deep belief network. J. Northeast. Univ. (Natural Science) 41(05), 609 (2020).

X. Zhou, J. Li, B. Fang, and H. Miao, Preparation method and technological condition effects of tce rare earth polishing powder. Rare Earth 06, 33 (2003).

Funding

The funding was provided by Key Research and Development Program of Jiangxi Province (Grant No. 20192BBE50010). Project supported by the Jiangxi Province Key Innovation R&D Platform Plan (20181BCD40009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, X., Wu, X., Liu, F. et al. Recognition of Carbon Content of Pr-Nd Alloys Based on Mel-Frequency Cepstrum Coefficient of Force Signals. JOM 74, 3454–3465 (2022). https://doi.org/10.1007/s11837-022-05384-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05384-z