Abstract

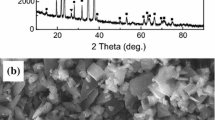

B4C-45vol.% (TiZrHfNbTa) B2 composite was prepared by in-situ reactive spark plasma sintering at 2000°C using powders of transition metal carbides and amorphous boron as raw materials. The composite reached a relative density of over 97% Within 6 min. The simultaneously generated B4C and (TiZrHfNbTa) B2 phases had homogeneous microstructures with particle sizes ~ 1 μm, and Nb segregations in (TiZrHfNbTa) B2 grains were detected. The composite obtained a high three-point bending strength of 422 MPa, a Vickers hardness of 20.9 GPa and a fracture toughness of 5.48 MPa m1/2, respectively. The fine grain and solid solution effects are the main reasons for the improved properties. The crack deflection, branching, and bridging mechanisms observed are also helpful for an improved fracture toughness of the composite. This work provides a fast, convenient method of preparing novel B4C high-entropy boride composite ceramics with enhanced properties.

Similar content being viewed by others

References

F. Thévenot, J. Eur. Ceram. Soc. 6, 205. (1990).

A.K. Suri, C. Subramanian, J.K. Sonber, and T.S.R.C. Murthy, Int. Mater. Rev. 55, 4. (2010).

W. Zhang, S. Yamashita, and H. Kita, Adv. Appl. Ceram. 118, 222. (2019).

Z. Zhang, X. Du, Z. Li, W. Wang, J. Zhang, and Z. Fu, J. Eur. Ceram. Soc. 34, 2153. (2014).

L.S. Sigl, J. Eur. Ceram. Soc. 18, 1521. (1998).

Yu.G. Tkachenko, V.T. Varchenko, V.F. Britun, and D.Z. Yurchenko, Powder Metall. Met. Ceram. 44, 245. (2005).

Y. Xiong, X. Du, M. Xiang, H. Wang, W. Wang, and Z. Fu, J. Eur. Ceram. Soc. 38, 4167. (2018).

Z. Liu, D. Wang, J. Li, Q. Huang, and S. Ran, Scr. Mater. 135, 15. (2017).

X. Cheng, R. He, Z. Qu, S. Ai, and D. Fang, Ceram. Int. 41, 14574. (2015).

J. Gild, Y. Zhang, T. Harrington, S. Jiang, T. Hu, M.C. Quinn, W.M. Mellor, N. Zhou, K. Vecchio, and J. Luo, Sci. Rep. 6, 37946. (2016).

C. Oses, C. Toher, and S. Curtarolo, Nat Rev Mater 5, 295. (2020).

R.-Z. Zhang and M.J. Reece, J. Mater. Chem. A 7, 22148. (2019).

Y. Zhang, S.-K. Sun, W. Zhang, Y. You, W.-M. Guo, Z.-W. Chen, J.-H. Yuan, and H.-T. Lin, Ceram. Int. 46, 14299. (2020).

D. Hedman, A.C. Feltrin, Y. Miyamoto, and F. Akhtar, J. Mater. Sci. 57, 422. (2022).

H. Zhang, D. Hedman, P. Feng, G. Han, and F. Akhtar, Dalton Trans. 48, 5161. (2019).

H. Zhang and F. Akhtar, Entropy 21, 474. (2019).

H. Xiang, Y. Xing, F. Dai, H. Wang, L. Su, L. Miao, G. Zhang, Y. Wang, X. Qi, L. Yao, H. Wang, B. Zhao, J. Li, and Y. Zhou, J. Adv. Ceram. 10, 385. (2021).

S.-K. Sun, G.-J. Zhang, W.-W. Wu, J.-X. Liu, T. Suzuki, and Y. Sakka, Scripta Mater 69, 139. (2013).

M. Qin, J. Gild, H. Wang, T. Harrington, K.S. Vecchio, and J. Luo, J. Eur. Ceram. Soc. 40, 4348. (2020).

J. Gu, J. Zou, P. Ma, H. Wang, J. Zhang, W. Wang, and Z. Fu, J. Mater. Sci. Technol. 35, 2840. (2019).

A.G. Evans and E.A. Charles, J. Am. Ceram. Soc. 59, 371. (1976).

Y. Zhang, D.-W. Tan, W.-M. Guo, L.-X. Wu, S.-K. Sun, Y. You, H.-T. Lin, and C.-Y. Wang, J. Am. Ceram. Soc. 103, 103. (2020).

R.M. White and E.C. Dickey, J. Eur. Ceram. Soc. 34, 2043. (2014).

Q. Yang, C. Hwang, A.U. Khan, V. Domnich, E.D. Gronske, and R.A. Haber, Mater. Charact. 155, 109797. (2019).

R. Tu, N. Li, Q. Li, S. Zhang, L. Zhang, and T. Goto, J. Eur. Ceram. Soc. 36, 3929. (2016).

D. Demirskyi and Y. Sakka, J. Ceram. Soc. Jpn. 123, 33. (2015).

D. Demirskyi, Y. Sakka, and O. Vasylkiv, J. Am. Ceram. Soc. 99, 2436. (2016).

L. Feng, W.G. Fahrenholtz, G.E. Hilmas, and F. Monteverde, J. Eur. Ceram. Soc. 41, 92. (2021).

Y. Zhou, H. Xiang, Z. Feng, and Z. Li, J. Mater. Sci. Technol. 31, 285. (2015).

H. Li and R.C. Bradt, J. Mater. Sci. 28, 917. (1993).

J.-X. Liu, X.-Q. Shen, Y. Wu, F. Li, Y. Liang, and G.-J. Zhang, J. Adv. Ceram. 9, 503. (2020).

Y. Zhang, S.-K. Sun, W.-M. Guo, L. Xu, W. Zhang, and H.-T. Lin, J. Adv. Ceram. 10, 173. (2021).

J. Gu, J. Zou, S.-K. Sun, H. Wang, S.-Y. Yu, J. Zhang, W. Wang, and Z. Fu, Sci. China Mater. 62, 1898. (2019).

H. Chen, H. Xiang, F.-Z. Dai, J. Liu, and Y. Zhou, J. Mater. Sci. Technol. 35, 2404. (2019).

F. Monteverde and F. Saraga, J. Alloy Compd. 824, 153930. (2020).

K.E. Spear, J. Less Common. Met. 47, 195. (1976).

M. Qin, J. Gild, C. Hu, H. Wang, M.S.B. Hoque, J.L. Braun, T.J. Harrington, P.E. Hopkins, K.S. Vecchio, and J. Luo, J. Eur. Ceram. Soc. 40, 5037. (2020).

X.-Q. Shen, J.-X. Liu, F. Li, and G.-J. Zhang, Ceram. Int. 45, 24508. (2019).

H. Engqvist, S. Jacobson, and N. Axén, Wear 252, 384. (2002).

X. Zhang, Z. Zhang, R. Wen, G. Wang, X. Zhang, J. Mu, H. Che, and W. Wang, Ceram. Int. 44, 2615. (2018).

D. Demirskyi, T.S. Suzuki, K. Yoshimi, and O. Vasylkiv, J. Ceram. Soc. Jpn. 128, 977. (2020).

H.J. Klam, H. Hahn, and H. Gleiter, Acta Metall. 35, 2101. (1987).

G.V. Tsagareishvili, T.G. Nakashidze, J.S. Jobava, G.P. Lomidze, D.E. Khulelidze, D.S. Tsagareishvili, and O.A. Tsagareishvili, J. Less Common. Met. 117, 159. (1986).

W.S. Rubink, V. Ageh, H. Lide, N.A. Ley, M.L. Young, D.T. Casem, E.J. Faierson, and T.W. Scharf, J. Eur. Ceram. Soc. 41, 3321. (2021).

L. Feng, F. Monteverde, W.G. Fahrenholtz, and G.E. Hilmas, Scr. Mater. 199, 113855. (2021).

Y. Zhang, Z.-B. Jiang, S.-K. Sun, W.-M. Guo, Q.-S. Chen, J.-X. Qiu, K. Plucknett, and H.-T. Lin, J. Eur. Ceram. Soc. 39, 3920. (2019).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 52002003, 52072003 and U1860102), Natural Science Foundation of Anhui Province, China (No. 2008085QE196), and Open Fund of Key Laboratory of Green Fabrication and Surface Technology of Advanced Metal Materials (Anhui University of Technology), Ministry of Education (No. GFST2020KF09).

Funding

National Natural Science Foundation of China, 52002003, Dong Wang, 52072003, Songlin.Ran, U1860102, Songlin Ran, Natural Science Foundation of Anhui Province, 2008085QE196, Dong Wang, Open fund of Key Laboratory of Green Fabrication and Surface Technology of Advanced Metal Materials (Anhui University of Technology), Ministry of Education, GFST2020KF09, Dong Wang

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, D., Xu, K., Li, Q. et al. Microstructure and Mechanical Properties of In-Situ B4C-(TiZrHfNbTa) B2 Composite by Reactive Spark Plasma Sintering. JOM 74, 4129–4137 (2022). https://doi.org/10.1007/s11837-022-05377-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05377-y