Abstract

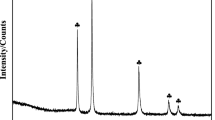

MgO is crucial for improving the softening–melting properties of pellets. By considering primary slags of magnesium pellets with high FeO and SiO2 and moderate MgO contents, the effect of MgO/SiO2 and FeO contents on the softening–melting behaviors of a MgO-SiO2-FeO slag system were studied. Relevant mechanisms were clarified using FactSage 7.0, XRD, and EPMA. By increasing the MgO/SiO2 ratio from 0.3 to 0.9, the softening and melting temperatures of the slag increased by approximately 30°C. As the FeO content increased from 5% to 20%, the softening and melting temperatures of the slag decreased from 1368°C to 1271°C and 1395°C to 1342°C, respectively. The MgO/SiO2 and FeO contents had little effect on the permeation temperature. Increasing the MgO/SiO2 ratio improved the softening and melting temperatures of slag; however, increasing the FeO content decreased these temperatures owing to the substitution effect of Mg2+ on Fe2+.

Similar content being viewed by others

References

G.Q. Zuo, ISIJ Int. 40, 1195. https://doi.org/10.2355/isijinternational.40.1195 (2000).

A. Kemppainen, K.I. Ohno, M. Iljana, O. Mattila, T. Paananen, E.P. Heikkinen, T. Maeda, K. Kunitomo, and T. Fabritius, ISIJ Int. 55, 2039. https://doi.org/10.2355/isijinternational.ISIJINT-2015-023 (2015).

J.R. Kim, Y.S. Lee, D.J. Min, S.M. Jung, and S.H. Yi, ISIJ Int. 44, 1291. https://doi.org/10.2355/isijinternational.44.1291 (2004).

Y.S. Lee, D.J. Min, S.M. Jung, and S.H. Yi, ISIJ Int. 44, 1283. https://doi.org/10.2355/isijinternational.44.1283 (2004).

G.H. Li, Z.K. Tang, Y.B. Zhang, Z.X. Cui, and T. Jiang, Ironmak. Steelmak. 37, 393. https://doi.org/10.1179/030192310X12690127076352 (2010).

C. Feng, M.S. Chu, J. Tang, Y.T. Tang, and Z.G. Liu, Steel Res. Int. 87, 1274. https://doi.org/10.1002/srin.201500355 (2016).

H.L. Liang, M.S. Chu, C. Feng, J. Tang, Z.G. Liu, and W.P. Wang, Ironmak. Steelmak. 47, 106. https://doi.org/10.1080/03019233.2018.1482819 (2020).

F.L. Qi, Y.L. Huang, and X.G. Si, Hebei Metall. 39, 39. https://doi.org/10.13630/j.cnki.13-1172.2017.0610 (2017).

H. Guo, F.M. Shen, L. Zhang, and X. Jiang, J. Northeast. Univ. 39, 990. https://doi.org/10.12068/j.issn.1005-3026.2018.07.016 (2018).

A.Y. Zheng, Z.J. Liu, D.Q. Cang, Y.Z. Wang, and J.L. Zhang, Chin. J. Eng. 40, 184. https://doi.org/10.13374/j.issn2095-9389.2018.02.008 (2018).

X. Jiang, L. Zhang, G.S. Li, M.F. Jin, Z. Wang, Y.S. Shen, and F.M. Shen, in Proceedings of International Congress on Science & Technology of Ironmaking, Shanghai, China (2009).

M.M. Zhang, and M.W. Andrade, in Characterization of Minerals Metals and Materials. ed. by I.S. Jamil, B. Li, and J.S. Carpenter (Springer, Berlin, 2016), pp. 167–174.

S. Dwarapudi, C. Sekhar, I. Paul, K. Modi, A.R. Pal, U. Chakraborty, and B.K. Das, Int. J. Metallurg. Eng. 6, 18. https://doi.org/10.5923/j.ijmee.20170601.03 (2017).

Y.J. Wang, H.B. Zuo, and J. Zhao, Ironmak. Steelmak. 47, 640. https://doi.org/10.1080/03019233.2020.1794471 (2020).

F.M. Zhang, W.H. Zhang, G.L. Qing, Q.S. Wang, and Z.G. Han, Sinter. Pelletiz. 46, 66. https://doi.org/10.13403/j.sjqt.2021.01.011 (2021).

K.K. Bai, L.C. Liu, Y.Z. Pan, H.B. Zuo, and Q.G. Xue, Ironmak. Steelmak. 48, 1. https://doi.org/10.1080/03019233.2021.1911770 (2021).

D.Q. Zhu, T.J. Chun, J. Pan, and J.L. Zhang, Int. J. Miner. Process. 125, 51. https://doi.org/10.1016/j.minpro.2013.09.008 (2013).

Q.J. Gao, F.M. Shen, G. Wei, X. Jiang, and H.Y. Zheng, J. Iron Steel Res. Int. 7, 28. https://doi.org/10.1016/S1006-706X(13)60121-1 (2013).

T.C. Eisele, and S.K. Kawatra, Miner. Process. Extr. Metall. Rev. 24, 1. https://doi.org/10.1080/08827500306896 (2003).

Q.J. Gao, Preparation of MgO Bearing Additive for Pellet and Mechanism Investigation of It on the Effect to Quality of Pellets (Northeastern University, Shenyang, 2014). https://kns.cnki.net/kcms/detail/detail.aspx?FileName=1016009101.nh&DbName=CDFD2017.

Q.J. Gao, X. Jiang, G. Wei, F.M. Shen, and J. Cent, South Univ. 21, 877. https://doi.org/10.1007/s11771-014-2013-5 (2014).

F.M. Shen, Q.J. Gao, G. Wei, X. Jiang, and Y.S. Shen, Steel Res. Int. 86, 644. https://doi.org/10.1002/srin.201400372 (2015).

S. Ueda, T. Kon, T. Miki, S.J. Kim, and H. Nogami, Metall. Mater. Trans. B 47, 2371. https://doi.org/10.1007/s11663-016-0683-0 (2016).

S. Ueda, T. Kon, T. Miki, S.J. Kim, and H. Nogami, ISIJ Int. 55, 2098. https://doi.org/10.2355/isijinternational.ISIJINT-2015-269 (2015).

H.C. Chuang, W.S. Hwang, and S.H. Liu, Mater. Trans. 50, 1448. https://doi.org/10.2320/matertrans.MRA2008372 (2009).

M. Iljana, A. Kemppainen, T. Paananen, O. Mattila, E.P. Heikkinen, and T. Fabritius, ISIJ Int. 56, 1705. https://doi.org/10.2355/isijinternational.ISIJINT-2016-117 (2016).

T. Kon, S. Sukenaga, and S. Ueda, ISIJ Int. 57, 1166. https://doi.org/10.2355/isijinternational.ISIJINT-2017-008 (2017).

S. Ueda, T. Miki, S.J. Kim, G. Xu, and S.Y. Kitamura, ISIJ Int. 60, 1380. https://doi.org/10.2355/isijinternational.ISIJINT-2019-136 (2020).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Number U1960205).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bai, K., Zuo, H., Wang, Y. et al. Softening–Melting Behaviors of a MgO-SiO2-FeO Slag System on a Coke Bed. JOM 74, 2019–2028 (2022). https://doi.org/10.1007/s11837-022-05167-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05167-6