Abstract

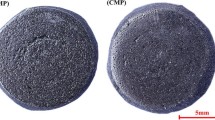

Because of the problems associated with pulverized charge in rotary kilns of the rotary kiln pre-reduction and bath smelting process, we proposed that the pulverized charge was granulated moderately to produce carbon-bearing pellets, and the particle size range was limited. In this work, we mainly investigated the effect of smelting temperature and smelting time on the reduction and melting separation of the pellets. The results indicated that the pellets could achieve a high metallization ratio and favorable separation when the proportion of the pellets with particle size of 2–5 mm was more than 60%, the smelting temperature was 1500–1550°C, and the smelting time was 160–200 s. This moderate granulation of the pulverized charge is effective in reducing energy consumption and increasing production efficiency of the process when the range of particle sizes of the pellets is controlled.

Similar content being viewed by others

References

J. Wang, Y.Y. Zhang, K.K. Cui, T. Fu, and T.S. Algarni, J. Clean. Prod. 298, 126788 (2021).

T. Koichi, N. Taihei, S. Michitaka, and A. Tatsuro, ISIJ Int. 55, 1866 (2015).

J. Zhao, H.B. Zuo, Y.J. Wang, J.S. Wang, and Q.G. Xue, Ironmak. Steelmak. 47, 296 (2020).

T. Fu, K.K. Cui, Y.Y. Zhang, J. Wang, F.Q. Shen, L.H. Yu, J.M. Qie, and X. Zhang, J. Alloy. Compd. 884, 161057 (2021).

K.K. Cui, T. Fu, Y.Y. Zhang, J. Wang, H.B. Mao, and T.B. Tan, J. Eur. Ceram. Soc. 41, 7935–7945 (2021).

Y.Y. Zhang, L.H. Yu, T. Fu, J. Wang, F.Q. Shen, and K.K. Cui, J. Alloy. Compd. 894, 162403 (2022).

W. Li, G.Q. Fu, M.S. Chu, and M.Y. Zhu, Steel Res. Int. 88, 1 (2017).

L.S. Zhao, L.N. Wang, D.S. Chen, H.X. Zhao, Y.H. Liu, and T. Qi, Trans. Nonferrous Met. Soc. 25, 1325 (2015).

T. Hu, X.W. Lv, and C.G. Bai, Steel Res. Int. 87, 494 (2016).

W. Li, G.Q. Fu, M.S. Chu, and M.Y. Zhu, Steel Research Int. 87, 1 (2016).

Y.Y. Zhang, T. Fu, K.K. Cui, F.Q. Shen, J. Wang, L.H. Yu, and H.B. Mao, Vacuum 191, 110297 (2021).

Y.Y. Zhang, L.H. Yu, T. Fu, J. Wang, F.Q. Shen, K.K. Cui, and H. Wang, Surf. Coat. Tech. 431, 128037 (2022).

P. Eungyeul, L. Sangbeom, O. Oleg, M. Dongjun, and R. Changhee, ISIJ Int. 44, 214 (2004).

J.B. Zhang, G.Y. Zhang, Q.S. Zhu, C. Lei, Z.H. Xie, and H.Z. Li, Metall. Mater. Trans. B 45, 914 (2014).

K.K. Cui, Y.Y. Zhang, T. Fu, S. Hussain, T.S. AlGarni, J. Wang, X. Zhang, and S. Ali, Coatings 11(2), 234 (2021).

G.Q. Zhang and O. Oleg, Metall. Mater. Trans. B 3, 129 (2000).

J.Y. Song, Z.Y. Jiang, C. Bao, and A.J. Xu, Metals 9, 364 (2019).

Y.Y. Zhang, K.K. Cui, T. Fu, J. Wang, F.Q. Shen, X. Zhang, and L.H. Yu, Ceram. Int. 47(16), 23053–23065 (2021).

T. Christoph, T. Tamara, L.S. Johannes, L.K. Werner, F.P. Jan, and S. Stefan, Steel Res. Int. 83, 181 (2012).

K.C. Jin, M.L. Seung, and S.S. Min, ISIJ Int. 58, 2228 (2018).

Acknowledgements

This work was supported by the National Key Research and Development Program of China under Grant No. 2017YFB0603800 & 2017YFB0603802; National Key Research and Development Program of China under Grant No. 2017YFC0210301; National Natural Science Foundation of China under Grant No.51234003.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qie, J., Zhang, Y., Wang, J. et al. Reduction and Melting Behavior of Pre-reduction Metallized Carbon-Bearing Pellets in Iron Bath Smelting Reduction Furnace. JOM 74, 2348–2356 (2022). https://doi.org/10.1007/s11837-021-05104-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-05104-z