Abstract

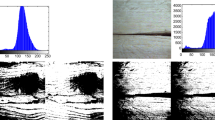

Inert gas bubbling is widely applied in the ladle refining of molten steel to ensure homogeneity and to promote chemical reactions between the slag and the metal phases. Monitoring the slag behavior is important for controlling the steel quality. In the present study, an image segmentation algorithm based on the hue-saturation-value color space has been proposed to realize the automatic detection and calculation of the slag eye area. Laboratory experiments show that the developed method was stable and yielded accurate results, which could be applied to automatic industrial image detection. In addition, the proposed methodology is promising in other fields, such as the evaluation of particle diameter for the identification of aggregate size, detection of material cracks, and measurement of the lining thickness of a furnace.

Similar content being viewed by others

References

Q.N. Hoang, M.A. Ramírez-Argáez, A.N. Conejo, B. Blanpain, and A. Dutta, JOM 70, 2109 (2018)

F. Tan, S. Jin, Z. He, and Y. Li, JOM 73, 2911 (2021)

L. Li and B. Li, JOM 68, 2160 (2016)

E.K. Ramasetti, V.V. Visuri, P. Sulasalmi, R. Mattila, and T. Fabritius, Steel Res. Int. 90, 1800365 (2019)

F. Tan, Z. He, S. Jin, L. Pan, Y. Li, and B. Li, Steel Res. Int. 91, 1900606 (2020)

F. Tan, S. Jin, Z. He, and Y. Li J. Iron Steel Res. Int. https://doi.org/10.1007/s42243-021-00647-6 (2021)

Z. Liu, L. Li, and B. Li, ISIJ Int. 57, 1971 (2017)

S. Chatterjee and K. Chattopadhyay, Metall. Mater. Trans. B 47, 508 (2016)

L. Wu, P. Valentin, and D. Sichen, Steel Res. Int. 81, 508 (2010)

W. Liu, H. Tang, S. Yang, M. Wang, J. Li, Q. Liu, and J. Liu, Metall. Mater. Trans. B 49, 2681 (2018)

N. Lv, L. Wu, H. Wang, Y. Dong, and C. Su, J. Iron Steel Res. Int. 24, 243 (2017)

E.S. Gadelmawla, Measurement 100, 36 (2017)

Subagyo and G.A. Brooks, ISIJ Int. 43, 1286 (2003)

K.J. Graham, K. Krishnapisharody, G.A. Irons, and J.F. MacGregor, Can. Metall. Q. 46, 397 (2007)

X. Xu, G.A. Brooks, W. Yang, and S. Curic, Ironmak. Steelmak. 37, 620 (2010)

X. Xu, G.A. Brooks, and W. Yang, Metall. Mater. Trans. B 41, 1025 (2010)

B. Yu, EURASIP J. Image. Video Process. 2019, 1 (2019)

N. Ostu, O. Nobuyuki, and N. Otsu, IEEE Trans. Syst. Man Cybern. 9, 62 (1979)

A.P. Chakkaravarthy and A. Chandrasekar, 3D Res. 10, 1 (2019)

A. Wunnava, M.K. Naik, R. Panda, B. Jena, and A. Abraham, Appl. Soft. Comput. 95, 106526 (2020)

H. Jiang, L. Zeng, and B. Bi, Opt. Laser. Eng. 51, 34 (2013)

J.P. Rodríguez, D.C. Corrales, J.-N. Aubertot, and C. Corrales, Pattern. Recognit. Lett. 136, 142 (2020)

E. Hamuda, B. McGinley, M. Glavin, and E. Jones, Comput. Electron. Agric. 133, 97 (2017)

V. Chernov, J. Alander, and V. Bochko, Comput. Electr. Eng. 46, 328 (2015)

M.Á. Castillo-Martínez, F.J. Gallegos-Funes, B.E. Carvajal-Gámez, G. Urriolagoitia-Sosa, and A.J. Rosales-Silva, Comput. Electron. Agric. 178, 105783 (2020)

T.F. Chan, S.H. Kang, and J. Shen, J. Vis. Commun. Image Represent. 12, 422 (2001)

K.B. Shaik, P. Ganesan, V. Kalist, B.S. Sathish, and J.M.M. Jenitha, Procedia Comput. Sci. 57, 41 (2015)

M.R. Olson, E. Graham, S. Hamad, P. Uchupalanun, N. Ramanathan, and J.J. Schauer, Sci Total. Environ. 548, 252 (2016)

S.J.G. Shoba and A.B. Therese, Biomed. Signal Process. 62, 101986 (2020)

M. Ezzahmouly, A. Elmoutaouakkil, M. Ed-Dhahraouy, H. Khallok, A. Elouahli, A. Mazurier, A. ElAlbani, and Z. Hatim, Heliyon 5, e02557 (2019)

Z. Wang, Expert Syst. Appl. 145, 113102 (2020)

T. Ellis, A. Abbood, and B. Brillault, Image Vis. Comput. 10, 136 (1992)

A. Fitzgibbon, M. Pilu, and R.B. Fisher, IEEE. Trans. Pattern Anal. 21, 476 (1999)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China [Grant Nos. 51974211, 12072245, and 51834002] and the Special Project of Central Government for Local Science and Technology Development of Hubei Province [Grant Nos. 2019ZYYD003, 2019ZYYD076].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, G., Tan, F., Jin, S. et al. Automatic Detection of Slag Eye Area Based on a Hue-Saturation-Value Image Segmentation Algorithm. JOM 74, 2921–2929 (2022). https://doi.org/10.1007/s11837-021-05094-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-05094-y