Abstract

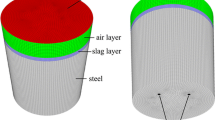

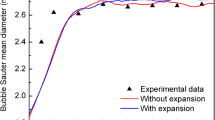

Ladle refining plays a key role in the steelmaking process. During the refining, a bubbly gas stream is used for mixing and to enhance the rate of removal of impurities from the molten steel. A numerical model has been developed to understand mass transfer and mixing behavior in a three-phase gas-stirred ladle. A two-resistance approach was used for the liquid–liquid mass transfer, while the mass transfer coefficient was determined using the Small Eddy theory. The model was validated with experimental data, obtained from a water–oil physical model simulating an industrial ladle with a scale factor of 1/17, valid for axisymmetric gas injection. Three variables were included to study the mass transfer behavior, namely gas flow rate, Q, oil (slag) thickness, h, and oil (slag) viscosity, \( \mu_{\text{o}} \). The gas flow rate ranged from 2.85 L/min to 8.56 L/min to meet industrial operating conditions. It was found that: (1) the volumetric mass transfer coefficient (ka) increases when the gas flow rate (Q) increases; and (2) increasing slag (oil) thickness has a positive influence on mass transfer as it considerably increases the interfacial area and promotes turbulence at the interface. At this range of gas flow rate, the effect of slag (oil) viscosity is limited. A general correlation was established: \( {\text{ka}} = 0.058Q^{0.459} h^{0.612} \). Mixing time was studied within the same flow rate range to observe its influence on the mass transfer. Mixing in the ladle is accomplished in a much shorter time than interphase mass transfer, specifically by two orders of magnitude, which indicates that mass transfer is the rate-limiting step.

Similar content being viewed by others

References

S. Du, Improving Process Design in Steelmaking, Fundamentals of Metallurgy (Cambridge: Woodhead Publishing Limited, 2005), pp. 369–398.

A. Ghosh, Secondary Steel Making: Principles and Applications (Boca Raton: CRC Press LLC, 2001).

G.J.W. Kors and P.C. Glaws, Ladle Refining and Vacuum Degassing, the Making, Shaping and Treating of Steel (Pittsburgh: The AISE Steel Foundation, 1998), pp. 661–713.

S. Kim and R.J. Fruehan, Metall. Trans. B 18B, 381–390 (1987).

K. Mori, Trans. ISIJ 28, 246–261 (1988).

K. Ogawa and T. Onoue, ISIJ Int. 29, 148–153 (1989).

M. Martín, M. Rendueles, and M. Díaz, Chem. Eng. Res. Des. 83, 1076–1084 (2005).

A. Dutta, R.P. Ekatpure, G.J. Heynderickx, A. de Broqueville, and G.B. Marin, Chem. Eng. Sci. 65, 1678–1693 (2010).

D. Mazumdar and R.I.L. Guthrie, ISIJ Int. 35, 1–20 (1995).

P.G. Jönsson and L.T.I. Jonsson, ISIJ Int. 41, 1289–1302 (2001).

D. Mazumdar and J.W. Evans, ISIJ Int. 44, 447–461 (2004).

G.A. Irons, A. Senguttuvan, and K. Krishnapisharody, ISIJ Int. 55, 1–6 (2015).

Y. Zang, X. Zang, B. Xu, W. Cai, and F. Wang, Can. J. Chem. Eng. 93, 2307–2314 (2015).

J.L. Xia, T. Ahokaien, and L. Holappa, Scand. J. Metall. 30, 69–76 (2001).

J.L. Xia and T. Ahokaien, Metall. Mater. Trans. B 32, 733–741 (2001).

H. Türkoğlu and B. Farouk, Metall. Trans. B 21, 771–781 (1990).

W. Lou and M. Zhu, Metall. Mater. Trans. B 44, 1251–1263 (2013).

G. Venturini and M.B. Goldschmit, Metall. Mater. Trans. B 38, 461–475 (2007).

M. Al-Harbi, H.V. Atkinson, and S. Gao, Proceedings of the XIth MCWASP (Opio, 2006).

B. Li, H. Yin, C.Q. Zhou, and F. Tsukihashi, ISIJ In. 48, 1704–1711 (2008).

U. Singh, R. Anapagaddi, S. Mangal, K.A. Padmanabhan, and A.K. Singh, Metall. Mater. Trans. B 47B, 1804–1816 (2016).

S. Lin, H. Chen, and D. Xie, Asia-Pacific Energy Equipment Engineering Research Conference (2015), pp. 310–313.

K. Nakanishi, J. Szekely, and C.W. Chang, Ironmaking Steelmaking 2, 115–124 (1975).

S. Asai, T. Okamoto, J. He, and I. Muchi, Trans. ISIJ 23, 43–50 (1983).

M. Zhu, T. Inomoto, I. Sawada, and T. Hsiao, ISIJ Int. 35, 472–479 (1995).

S.W.P. Cloeete, J.J. Eksten, and S.M. Bradshaw, Miner. Eng. 46–47, 16–24 (2013).

S. Ganguly and S. Chakraborty, Ironmaking Steelmaking 35, 524–530 (2008).

W. Lao and M. Zhu, ISIJ Int. 54, 9–18 (2014).

L. Li, Z. Liu, B. Li, H. Matsuura, and F. Tsukihashi, ISIJ Int. 55, 1337–1346 (2015).

M.A. Ramirez-Argaez, A. Conejo, and A. Amaro-Villeda, ISIJ Int. 54, 1–8 (2014).

A. Chaendera and R.H. Eric, Effect of Slag Phase on Mixing and Mass Transfer in a Model Creusot Loire Uddeholm (CLU) Converter (The Mineral, Metals & Materials Society, 2017), pp. 45–61.

L.T. Costa and R.P. Tavares, Mass Transfer-Advancement in Process Modelling, ed. by M. Solecki (InTech, New York, 2015), pp. 149–167.

Q. Cao, A. Pitts, and L. Nastac, Ironmaking Steelmaking 45, 280–287 (2018).

F.P. Incropera and D.P. DeWitt, Introduction to Heat Transfer (New York: Wiley, 2002).

J.C. Lamont and D.S. Scott, AIChE J. 16, 513–519 (1970).

V. Sahajwalla, J.K. Brimacombe, and M.E. Salcudean, Steelmaking Conf., Proceedings ISS, Vol. 72 (1989), pp. 497–501.

M. Ramírez-Argáez and C. González-Rivera, The 3rd Pan American Materials Congress (2017).

L. Dong, S.T. Johansen, and T.A. Engh, Can. J. Metall. Mater. Sci. 31, 299–307 (1992).

P.H. Calderbank and M.B. Moo-Young, Chem. Eng. Sci. 16, 39–54 (1961).

G.E. Fortescue and J.R.A. Pearson, Chem. Eng. Sci. 22, 1163–1176 (1967).

L.P. Hung, C.S. Garbe, and W. Tsai, The 6th International Symposium on Gas Transfer at Water Surfaces (2010), pp. 17–21.

ANSYS Fluent Theory Guide 17.0, ANSYS Inc, 2016

P.J. Roache, ASME J. Fluids Eng. 71, 405–413 (1994).

M. Hirasawa, K. Mori, M. Sano, A. Hatanaka, Y. Shimatani, and Y. Okazaki, Trans. ISIJ 27, 277–282 (1987).

D.G.C. Robertson and B.B. Staples, Process Engineering of Pyrometallurgy (Institution of Mining and Metallurgy, London, 1974), pp. 51–59.

S. Taniguchi, S. Kawaguchi, and A. Kikuchi, Appl. Math. Model. 26, 249–262 (2002).

Y. Ohga, S. Taniguchi, and J. Kikuchi, Tetsu-to-Hagane 71, S897 (1985).

M. Hirasawa, K. Mori, M. Sano, Y. Shimada, and Y. Okazaki, Tetsu-to-Hagane 71, S898 (1985).

S. Endo and M. Hasegawa, Tetsu-to-Hagane 71, S899 (1985).

S. Joo and R.I.L. Guthrie, Metall. Trans. B 23, 765–778 (1992).

S.P. Patil, D. Satish, M. Peranandhanathan, and D. Mazumdar, ISIJ Int. 50, 1117–1124 (2010).

D.Mazumdar, Fluid flow, Particle motion and mixing in ladle metallurgy operations, PhD Thesis, McGill University, Montreal, 1985

Q. Ying, L. Yun, and L. Liu, Scaninject III: 3rd International Conference on Refining of Iron and Steel by Powder Injection (Lulea, Sweden: MEFOS, 1983).

O. Haida, T. Emi, S. Yamada, and F. Sudo, Scaninject II: 2nd International Conference on Injection Metallurgy (Lulea, Sweden: MEFOS, 1980).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hoang, Q.N., Ramírez-Argáez, M.A., Conejo, A.N. et al. Numerical Modeling of Liquid–Liquid Mass Transfer and the Influence of Mixing in Gas-Stirred Ladles. JOM 70, 2109–2118 (2018). https://doi.org/10.1007/s11837-018-3056-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3056-0