Abstract

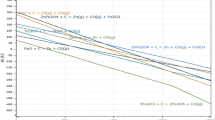

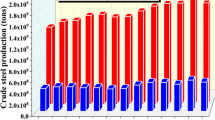

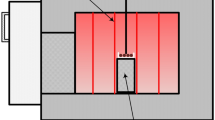

In the recycling of zinc from electric arc furnace dust using microwave-based furnaces, the use of graphite powder as a reductant results in significant greenhouse gas emissions. In this study, graphite was replaced by a non-carbonaceous reductant in the form of silicon powder. The sample is heated in a microwave-based furnace under 7.5 kW maximum power irradiation at 2.45 GHz. The results clearly indicate that the reaction proceeded between zinc ferrite and silicon powder. The maximum removal rate of zinc obtained was 80% in cases where more than 10 times the stoichiometric amount of silicon powder was used for a heating time of more than 20 min. The apparent activation energy of microwave-based heating was 115.39 kJ/mol lower than that when heating with a conventional furnace.

Similar content being viewed by others

References

T.E. Graedel, D. van Beers, M. Bertram, K. Fuse, R.B. Gordon, A. Gritsinin, E.M. Harper, A. Kapur, R.J. Klee, R. Lifset, L. Memon, and S. Spatari, J. Ind. Ecol. 9, 67. (2005).

P.B. Queneau, R. Leiby, and R. Robinson, World Metall. Erzmet. 68, 149. (2015).

X. Lin, Z. Peng, J. Yan, Z. Li, J.Y. Hwang, Y. Zhang, G. Li, and T. Jiang, J. Clean. Prod. 149, 1079. (2017).

C. Pichler, and J. Antrekowitsch, JOM 69, 999. (2017).

P.J.W.K. de Buzin, N.C. Heck, and A.C.F. Vilela, J. Mater. Res. Technol. 6, 194. (2017).

M.C. da Silva, A.M. Bernardes, C.P. Bergmann, J.A.S. Tenório, and D.C.R. Espinosa, Ironmak. Steelmak. 35, 315. (2008).

A.J.B. Dutra, P.R.P. Paiva, and L.M. Tavares, Miner. Eng. 19, 478. (2006).

J. Antrekowitsch, and H. Antrekowitsch, JOM 53, 26. (2001).

M. Zhang, J. Li, Q. Zeng, and Q. Mou, Appl. Sci. 9, 1. (2019).

J. Veres, M. Lovas, S. Jakabsky, V. Sepelak, and S. Hredzak, Hydrometallurgy 129–130, 67. (2012).

P.K. Hazaveh, S. Karimi, F. Rashchi, and S. Sheibani, Ecotoxicol. Environ. Saf. 202, 1. (2020).

F. Kukurugya, T. Vindt, and T. Havlík, Hydrometallurgy 154, 20. (2015).

D. Zhang, H. Ling, T. Yang, W. Liu, and L. Chen, J. Clean. Prod. 224, 536. (2019).

J. Aromaa, A. Kekki, A. Stefanova, H. Makkonen, and O. Forsén, Miner. Process. Extr Metall. 125, 242. (2016).

M. Omran, T. Fabritius, and E.P. Heikkinen, J. Sustain. Metall. 5, 331. (2019).

X. Sun, J.Y. Hwang, and X. Huang, JOM 60, 35. (2008).

D.E. Khaled, N. Novas, J.A. Gazquez, and F. Manzano-Agugliaro, Renew. Sustain. Energy Rev. 82, 2880. (2018).

Q. Ye, Z. Peng, G. Li, J. Lee, Y. Liu, M. Liu, L. Wang, M. Rao, Y. Zhang, T. Jiang, and A.C.S. Sustain, Chem. Eng. 7, 9515. (2019).

E. Kim, T. Kim, J. Lee, Y. Kang, and K. Morita, Ironmak. Steelmak. 39, 45. (2012).

R.E. Newnham, S.J. Jang, M. Xu, and F. Jones, Ceram. Trans. 21, 51. (1991).

Z. Peng, and J.Y. Hwang, Int. Mater. Rev. 60, 30. (2015).

A.K. Dasgupta, J. Mazumder, and P. Li, J. Phys. Appl. Phys. 102, 053108. (2007).

K.E. Haque, Int. J. Miner. Process. 57, 1. (1999).

S. Solomon, G.K. Plattner, R. Knutti, and P. Friedlingstein, Proc. Natl. Acad. Sci. USA 106, 1704. (2009).

D.C. Dube, M. Fu, D. Agrawal, R. Roy, and A. Santra, Mater. Res. Innov. 12, 119. (2008).

J. Cheng, D. Agrawal, Y. Zhang, R. Roy, and A.K. Santra, J. Alloys Compd. 491, 517. (2010).

E. Williams, Technol. Forecast. Soc. Change 70, 341. (2003).

S. Mukherjee, and P.B. Ghosh, Int. J. Low-Carbon Technol. 9, 52. (2014).

Y. Akira, and Y. Oshima, J. Supercrit. Fluids 75, 1. (2013).

K. Momoki, and J.W. Yan, Appl. Phys. Express 13, 026505. (2020).

T.C. Yang, F.C. Chang, C.Y. Peng, H.P. Wang, and Y.L. Wei, Environ. Technol. 36, 2987. (2015).

W.G. Jung, S.T. Hossain, F.T. Johra, J.H. Kim, and Y.C. Chang, J. Iron Steel Res. Int. 26, 806. (2019).

M.I. Davidzon, Int. J. Heat Mass Transf. 55, 5397. (2012).

K.C. Cheng, Appl. Mech. Rev. 62, 1. (2009).

J.J. Lee, C.I. Lin, and H.K. Chen, Metall. Mater. Trans. B 32, 1033. (2001).

B. Janković, S. Stopić, A. Güven, and B. Friedrich, J. Magn. Magn. Mater. 358–359, 105. (2014).

A. Amini, K. Ohno, T. Maeda, and K. Kunitomo, Sci. Rep. 8, 15023. (2018).

M. Hotta, M. Hayashi, and K. Nagata, ISIJ Int. 51, 491. (2011).

H. Sugawara, K. Kashimura, M. Hayashi, T. Matsumuro, T. Watanabe, T. Mitani, and N. Shinohara, Physica B 458, 35. (2015).

Z.W. Peng, J.Y. Hwang, J. Mouris, R. Hutcheon, and X. Sun, Metall. Mater. Trans. A 42A, 2259. (2011).

Z.Y. Liu, N.H. Loh, K.A. Khor, and S.B. Tor, Scr. Mater. 44, 1131. (2001).

W.P. Ye, Z.L. Huang, Q.X. Zhang, and Q.Y. Zhang, J. Wuhan Univ. Technol. Mater. Sci. 23, 528. (2008).

M.N. Magomedov, Tech. Phys. 61, 730. (2016).

S. Polsilapa, D.R. Sadedin, and P. Wangyao, High Temp. Mater. Process. 30, 587. (2011).

J. Fukushima, K. Kashimura, S. Takayama, and M. Sato, Chem. Lett. 41, 39. (2012).

J. Fukushima, K. Kashimura, S. Takayama, M. Sato, S. Sano, Y. Hayashi, and H. Takizawa, Mater. Lett. 91, 252. (2013).

J. Fukushima, K. Kashimura, and M. Sato, Mater. Chem. Phys. 131, 178. (2011).

M.A. Herrero, J.M. Kremsner, and C.O. Kappe, J. Org. Chem. 73, 36. (2008).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mizuno, N., Kosai, S. & Yamasue, E. Microwave-Based Approach to Recovering Zinc from Electric Arc Furnace Dust Using Silicon Powder as a Non-carbonaceous Reductant. JOM 73, 1828–1835 (2021). https://doi.org/10.1007/s11837-021-04677-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04677-z