Abstract

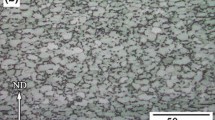

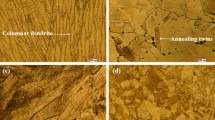

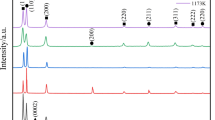

A challenge for the research and industrial community is to develop lightweight wrought Mg-based alloys that exhibit high strength and good ductility. To address this challenge, Mg-3Sn-2Al (TA32) alloy was produced by the squeeze casting process followed by hot rolling (HR). To improve its ductility, the hot-rolled alloy was annealed (HRA). HR and HRA samples were subjected to microstructural, composition, textural, and mechanical property analysis. The HR sheet exhibited high strength with 0.2% proof stress (PS) of 274 MPa and ultimate tensile strength (UTS) of 390 MPa, as well as reasonable ductility (12%) along the rolling direction, one of the highest values for Mg alloys. HRA sheet showed a moderate reduction in strength with a 0.2% PS of 250 MPa and UTS of 365 MPa, but an improvement in ductility (19%). The excellent properties of this alloy can be attributed to the synergistic effects of grain refinement, solid-solution strengthening by Al and Sn atoms, and uniform distribution of fine Mg2Sn particles.

Similar content being viewed by others

References

E. Aghion, B. Bronfin, and D. Eliezer, J. Mater. Process. Technol. 117, 381. https://doi.org/10.1016/S0924-0136(01)00779-8 (2001).

B. Mordike, and T. Ebert, B. Mordike, and T. Ebert, Mater. Sci. Eng. A 302, 37. https://doi.org/10.1016/S0921-5093(00)01351-4.N (2001).

K. Hono, C.L. Mendis, T.T. Sasaki, and K. Oh-Ishi, Scr. Mater. 63, 710. https://doi.org/10.1016/j.scriptamat.2010.01.038 (2010).

C. Bettles and M. Barnett, Advances in Wrought Magnesium Alloys: Fundamentals of Processing, Properties and Applications, 2012. ISBN 978-1-84569-968-0

I. Polmear, Light Alloys: Tradit. Alloys Nanocryst. https://doi.org/10.1017/S000192400008670X (2005).

L. Zheng, H. Nie, W. Zhang, W. Liang, and Y. Wang, Mater. Sci. Eng. A 722, 58. https://doi.org/10.1016/j.msea.2017.12.048 (2018).

L. Gao, R.S. Chen, and E.H. Han, J. Alloys Compd. 481, 379. https://doi.org/10.1016/j.jallcom.2008.04.049 (2009).

H.K. Lim, D.H. Kim, J.Y. Lee, W.T. Kim, and D.H. Kim, J. Alloys Compd. 468, 308. https://doi.org/10.1016/j.jallcom.2007.12.098 (2009).

Q. Peng, X. Hou, L. Wang, Y. Wu, Z. Cao, and L. Wang, Mater. Des. 30, 292. https://doi.org/10.1016/j.matdes.2008.04.069 (2009).

N.E. Mahallawy, A.A. Diaa, M. Akdesir, and H. Palkowski, Mater. Sci. Eng. A 680, 47. https://doi.org/10.1016/j.msea.2016.10.075 (2017).

D. Luo, N. Xia, H.-Y. Wang, L. Chen, J.-G. Wang, and Q.-C. Jiang, Mater. Sci. Technol. 30, 1305. https://doi.org/10.1179/1743284714Y.0000000565 (2014).

F. Qi, D. Zhang, X. Zhang, and X. Xu, J. Alloys Compd. 585, 656. https://doi.org/10.1016/J.JALLCOM.2013.09.156 (2014).

J. Chen, Z. Chen, H. Yan, F. Zhang, and K. Liao, J. Alloys Compd. 461, 209. https://doi.org/10.1016/j.jallcom.2007.07.066 (2008).

Z.-Z. Shi, J.-Y. Xu, J. Yu, and X.-F. Liu, Mater. Sci. Eng. A 712, 65. https://doi.org/10.1016/j.msea.2017.11.094 (2018).

W.L. Cheng, S.S. Park, B.S. You, and B.H. Koo, Mater. Sci. Eng. A 527, 4650. https://doi.org/10.1016/j.msea.2010.03.031 (2010).

Y. Chen, L. Jin, Y. Song, H. Liu, and R. Ye, Mater. Sci. Eng. A 612, 96. https://doi.org/10.1016/j.msea.2014.06.022 (2014).

D.H. Kim, Y.K. Kim, S.W. Sohn, D.H. Kim, and W.T. Kim, J. Alloys Compd. 549, 46. https://doi.org/10.1016/j.jallcom.2012.09.050 (2013).

ASM International, ASM Handbook, Volume 3, Alloy Phase Diagrams, vol. 7, 2004. https://doi.org/10.1007/BF02869318

W.N. Tang, S.S. Park, and B.S. You, Mater. Des. 32, 3537. https://doi.org/10.1016/J.MATDES.2011.02.012 (2011).

Y.N. Wang, and J.C. Huang, Mater. Chem. Phys. 81, 11. (2003).

N. Koundinya, L. Raman, N. Chawake, and R.S. Kottada, Materialia 3, 274. https://doi.org/10.1016/j.mtla.2018.09.001 (2018).

J. Koike, Metall. Mater. Trans. A 36A, 1689. https://doi.org/10.1007/s11661-005-0032-4 (2005).

J. Jiang, G. Bi, G. Wang, Q. Jiang, J. Lian, and Z. Jiang, J. Magn. Alloys 2, 116. https://doi.org/10.1016/J.JMA.2014.05.004 (2014).

H.-Y. Wu, and F.-Z. Lin, Mater. Sci. Eng. A 527, 1194. https://doi.org/10.1016/J.MSEA.2009.09.049 (2010).

C. Zhao, X. Chen, F. Pan, S. Gao, D. Zhao, and X. Liu, Mater. Sci. Eng. A 713, 244–252. https://doi.org/10.1016/J.MSEA.2017.12.074 (2018).

U.F. Kocks, and H. Mecking, Prog. Mater. Sci. https://doi.org/10.1016/S0079-6425(02)00003-8 (2003).

Y. Zou, L. Zhang, Y. Li, H. Wang, J. Liu, P.K. Liaw, H. Bei, and Z. Zhang, J. Alloys Compd. 735, 2625. https://doi.org/10.1016/j.jallcom.2017.12.025 (2018).

N. Afrin, D.L. Chen, X. Cao, and M. Jahazi, Scr. Mater. 57, 1004. https://doi.org/10.1016/j.scriptamat.2007.08.001 (2007).

H.Y. Wu, J.C. Yan, H.H. Tsai, C.H. Chiu, G.Z. Zhou, and C.F. Lin, Mater. Sci. Eng. A 527, 7197. https://doi.org/10.1016/j.msea.2010.08.019 (2010).

C.H. Cáceres, and A.H. Blake, Mater. Sci. Eng. A 462, 193. https://doi.org/10.1016/j.msea.2005.12.113 (2007).

A.D. Rollett, and U.F. Kocks, Solid State Phenom. 35–36, 1. https://doi.org/10.4028/www.scientific.net/SSP.35-36.1 (1993).

E.I. Poliak, and J.J. Jonas, Acta Mater. 44, 127. https://doi.org/10.1016/1359-6454(95)00146-7 (1996).

W.L. Cheng, Q.W. Tian, H. Yu, H. Zhang, and B.S. You, J. Magn. Alloys 2, 299–304. https://doi.org/10.1016/j.jma.2014.11.003 (2014).

G. Hu, D. Zhang, T. Tang, X. Shen, L. Jiang, J. Xu, and F. Pan, Mater. Sci. Eng. A 634, 5. https://doi.org/10.1016/j.msea.2015.03.040 (2015).

L. Gao, R.S. Chen, and E.H. Han, J. Alloys Compd. 472, 234. https://doi.org/10.1016/j.jallcom.2009.02.131 (2009).

J. Bohlen, M.R. Nürnberg, J.W. Senn, D. Letzig, and S.R. Agnew, Acta Mater. 55, 2101. https://doi.org/10.1016/J.ACTAMAT.2006.11.013 (2007).

Y. Chen, H. Liu, G.T. Gao, D. Fang, Y. Wang, L. Jin, and Y. Jiang, Key Eng. Mater. 727, 196 https://doi.org/10.4028/www.scientific.net/KEM.727.196 (2017).

N.E. Mahallawy, A.A. Diaa, M. Akdesir, and H. Palkowski, Materwiss. Werksttech. 47, 37. https://doi.org/10.1002/mawe.201500468 (2016).

Y.K. Kim, S.W. Sohn, D.H. Kim, W.T. Kim, and D.H. Kim, J. Alloys Compd. 549, 46. https://doi.org/10.1016/j.jallcom.2012.09.050 (2013).

L. Mao, C. Liu, Y. Gao, X. Han, S. Jiang, and Z. Chen, Mater. Sci. Eng. A 701, 7. https://doi.org/10.1016/j.msea.2017.06.008 (2017).

F.-S. Pan, J. Zhang, J.-F. Wang, M.-B. Yang, H. En-Hou, and C. Rong-Shi, Trans. Nonferrous Met. Soc. China 20, 1249. https://doi.org/10.1016/S1003-6326(09)60287-9 (2010).

G.H. Su, L. Zhang, L.R. Cheng, Y.B. Liu, and Z.Y. Cao, Trans. Nonferrous Met. Soc. China Engl. Ed. 20, 383. https://doi.org/10.1016/S1003-6326(09)60150-3 (2010).

J. Wei, J. Chen, H. Yan, B. Su, and X. Pan, J. Alloys Compd. 548, 52. https://doi.org/10.1016/J.JALLCOM.2012.08.102 (2013).

Acknowledgements

The authors gratefully acknowledged Prof. Satyam Suwas, Chairperson of the Department of Materials Engineering, Indian Institute of Science (IISc), Bangalore, India for allowing us to use characterization facilities available in the department.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Perugu, C.S., Verma, K.K., Madhu, H.C. et al. Microstructural and Texture Evolution of Hot-Rolled TA32 Alloy and Its Effect on Tensile Properties. JOM 73, 1428–1439 (2021). https://doi.org/10.1007/s11837-021-04615-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04615-z