Abstract

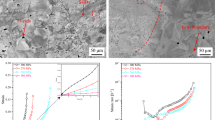

Inconel 740H® alloy is considered a leading candidate for advanced ultra-supercritical steam power generation at temperatures up to 750°C and pressures up to 35 MPa. Stable alloy microstructures for extremely long-term use are needed; however, extended exposure to high temperatures and stresses can lead to microstructural instabilities when the material is joined with other alloys, thereby decreasing component lifetime. It is, therefore, critical to understand the microstructural evolution of weldments of this alloy during high-temperature and high-pressure exposures. This research specifically aims to evaluate the effects of stress and joining processes on the lifetime of Inconel 740H welded with Thermanit 263 filler metal (based on Alloy 263™). Electron microscopy techniques were used to evaluate the evolution of \( \gamma^{\prime } \)-precipitates, grain boundary phases, grain sizes and boundary types, weldment interfaces, and other relevant microstructural characteristics resulting from long-term exposure at elevated temperatures (650–850°C) and external stresses (53–440 MPa) during creep testing. The creep strength of Inconel 740H weldments with Alloy 263 (740H/263) as a filler metal was less than that of Inconel 740H/740H base metal because of the microstructural instability of Alloy 263 at the subject creep temperatures.

Similar content being viewed by others

References

J. Shingledecker, R. Purgert, and P. Rawls, Advances in Materials Technology for Fossil Power Plants, ed. D. Gandy and J. Shingledecker (Materials Park,OH: ASMInt., 2014), p. 41.

P.S. Weitzel, J.M. Tanzosh, B. Boring, N. Okita, T. Takahashi, N, Ishikawa in Advanced Ultra-Supercritical Power Plant (700 to 760°C), Design for Indian Coal, Babcock & Wilcox Power Generation Group, Inc. Barberton, Ohio, USA, Power-Gen Asia, October 3–5, 2012 Bangkok, Thailand, Technical Paper No. BR-1884 1 (2012).

R. Viswanathan, J.F. Henry, J. Tanzosh, G. Stanko, J. Shingledecker, B. Vitalis, and R. Purgert, J. Mater. Eng. Perform. 14, 281 (2005).

A. Klenk and K. Maile, Advances in Materials Technology for Fossil Power Plants, ed. D. Gandy and J. Shingledecker (Materials Park: ASM Int., 2014), pp. 155–166.

P.F. Tortorelli, K.A. Unocic, H. Wang, M.L. Santella, and J.P. Shingledecker, Advances in Materials Technology for Fossil Power Plants, ed. D. Gandy and J. Shingledecker (Materials Park: ASM Int., 2014), p. 131.

P.F. Tortorelli, H. Wang, K.A. Unocic, M. L. Santella, J.P. Shingledecker, and V. Cedro, III, in Proceedings of ASME Symposium on Elevated Temperature Application of Materials for Fossil, Nuclear, and Petrochemical Industries (New York: ASME, 2014), ASME Paper ETS2014-1003 (2014).

S.J. Patel, J.J. de Barbadillo, B.A. Baker, and R.D. Gollihue, Procedia Eng. 55, 246 (2013).

G.D. Smith, H.W. Sizek, in Paper 00256, presented at the NACE Annual Conference Corrosion 2000, Orlando FL, March 26–31 (2000).

R.J. Smith, B.A. Baker, G.D. Smith, Nickel alloys for the next generation of advanced steam boilers, in VGB Materials and Quality Assurance Conference, March 10–11, Dortmund, Germany (2004).

J. de Barbadillo, B.A. Baker, L. Klingensmith, S.J. Patel, Nickel alloy development and use in USC boilers, in Symposium on Advanced Power Plant Heat Resistant Alloys, SPERI, Shanghai (2009).

G.S. Was, V. Thaveeprungsriporn, and D.C. Crawford, JOM 50, 44 (1998).

T. Watanabe, Mater. Sci. Eng., A A166, 11 (1993).

J.A. Siefert, J.M. Tanzosh, J.E. Ramirez, Weldability of INCONEL alloy 740, in Proceedings of 6th International Conference on Advances in Materials Technology for Fossil Power Plants; EPRI, Santa Fe, (2010).

J.-C. Zhao, V. Ravikumar, and A.M. Beltran, Metall. Mat. Trans. A 32A, 1271 (2001).

V. Ratna and D.S. Sarma, Scr. Metall. Mater. 29, 467 (1993).

B. Hicks, M. Heap: Report No. B48749, Lucas Gas Turbine Equipment Ltd., Materials Laboratory, Burnley, September 25 (1968).

J.P. Shingledecker and G.M. Pharr, Mater. Metall. Trans. A 43A, 1902 (2012).

K.A. Unocic, J.P. Shingledecker, and P.F. Tortorelli, JOM 66, 2535 (2014).

B.G. Choi, I.S. Kim, D.H. Kim, S.M. Seo, C.Y. Jo, Superalloy 2004, in K.A. Green, T.M. Pollock, H. Harada, TMS (The Minerals, Metals & Materials Society), 2004 T.E. Howson, R.C. Reed, J.J. Schirra, S, Walston (2004), p. 163.

Z. Zhu, H. Xu, H.I. Khan, and N. Zhang, Corros. Eng. Sci. Technol. 53, 617 (2018).

R.R. Unocic, N. Zhou, L. Kovarik, C. Shen, Y. Wang, and M.J. Mills, Acta Mater. 59, 7325 (2011).

T.M. Smith, R.R. Unocic, H. Deutchman, and M.J. Mills, Mater. High Temp. 33, 372 (2016).

L. Kovarik, R.R. Unocic, and M.J. Mills, Prog. Mater Sci. 54, 839 (2009).

M. Preuss, J.Q. da Fonseca, B. Grant, E. Knoche, R. Moat, M. Daymond, Superalloys 2008, TMS (the Minerals, Metals and Materials Society) (2008), p. 405.

Acknowledgements

Research sponsored by U.S. DOE, Office of Fossil Energy, Crosscutting Research Program. We are grateful to R.D. Golihue of Special Metals Corporation (SMC) for welding the Inconel 740H/Thermanit 263 plate and for providing the associated cross-weld creep specimens and the initial characterization results for the as-welded material, and to J.J. de Barbadillo and B.A. Baker of SMC for their consultation. Student participation was made possible by the Oak Ridge Institute for Science and Education. The authors thank Jackson Spurling, Tracie Lowe, Tom Geer, Dorothy Coffey, Jeremy L. Moser, and Andrés E. Márquez Rossy for assistance with the experimental procedure.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Unocic, K.A., Chen, X. & Tortorelli, P.F. Microstructural Evaluation of Welded Nickel-Based Superalloy Inconel 740H After Creep Testing. JOM 72, 1811–1821 (2020). https://doi.org/10.1007/s11837-020-04119-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04119-2