Abstract

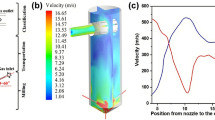

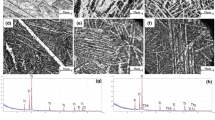

Titanium hydride powders are increasingly being used to produce titanium components via powder metallurgy processes due to their improvements in densification over titanium metal powders. Since the oxygen content plays a significant role in the mechanical properties of titanium alloys, understanding how powder preparation techniques, such as milling, affect the final oxygen content is key. In this work, titanium hydride powders were milled through jet milling using air, nitrogen, and argon gas at various processing pressures. The oxygen content in the sintered powders is shown to be mostly dependent on the specific surface area, which is mainly affected by the grinding pressure. The type of gas used was also found to have an effect on the oxygen content, but the dependence was small.

Similar content being viewed by others

References

O.M. Ivasishin, D.G. Savvakin, M.M. Gumenyak, and O.B. Bondarchuk, Key Eng. Mater. 520, 121 (2012).

Y. Zhang, Z.Z. Fang, L. Xu, P. Sun, B. Van Devener, S. Zheng, Y. Xia, P. Li, and Y. Zhang, J. Phys. Chem. C 122, 20691 (2018).

X.L. Han, Q. Wang, D.L. Sun, and H.X. Zhang, Scr. Mater. 56, 77 (2007).

O.M. Ivasishin, D.G. Savvakin, I.S. Bielov, V.S. Moxson, V.A. Duz, R. Davies, and C. Lavender, Mater. Sci. Technol. 151 (2005).

J. Greenspan, F.J. Rizzitano, and E. Scala, in Proceedings of the Second International Conference on Titanium Science Technology (1973), pp. 365–379.

J. Greenspan, F.J. Rizzitano, and E. Scala, Metal matrix composites by decomposition sintering of titanium hydride. Army Materials and Mechanics Research Center Technical Report 70-33 (1970).

O.M. Ivasishin, D. Eylon, V.I. Bondarchuk, and D.G. Savvakin, Defect Diffus. Forum 277, 177 (2008).

P. Sun, Z.Z. Fang, and M. Koopman, Adv. Eng. Mater. 15, 1007 (2013).

P. Sun, Z.Z. Fang, M. Koopman, Y. Xia, J. Paramore, K.S.R. Chandran, Y. Ren, and J. Lu, Metall. Mater. Trans. A 46, 5546 (2015).

P. Sun, Z.Z. Fang, M. Koopman, J. Paramore, and K.S.R. Chandran, Acta Mater. 84, 29 (2015).

J.D. Paramore, Z.Z. Fang, P. Sun, M. Koopman, K.S.R. Chandran, and M. Dunstan, Scr. Mater. 107, 103 (2015).

J.D. Paramore, Z.Z. Fang, M. Dunstan, P. Sun, and B.G. Butler, Sci. Rep. 7, 41444 (2017).

G. Lutjering and J.C. Williams, Titanium, 2nd ed. (Berlin: Springer, 2007).

E. Baril, L.P. Lefebvre, and Y. Thomas, Powder Metall. 54, 183 (2011).

C.G. McCracken, C. Motchenbacher, and D.P. Barbis, Int. J. Powder Metall. 46, 19 (2010).

C.G. McCracken, D.P. Barbis, and R.C. Deeter, Powder Metall. 54, 180 (2011).

I.I. Ivanova, N.A. Krylova, O.M. Demydyk, V.A. Barabash, and M.V. Karpets, Powder Metall. Met. Ceram. 58, 13 (2019).

S.L.G. Petroni, V.A.R. Henriques, M.S.M. Paula, and C.A.A. Cairo, Mater. Sci. Forum 727–728, 374 (2012).

S.L.G. Petroni, M.S.M. Paula, and V.A.R. Henriques, Powder Metall. 56, 202 (2013).

T.M. Motsai, S. Chikosha, C. Machio, and M.E. Makhatha, in IOP Conference Series: Materials Science and Engineering, vol 430 (2018).

L.R. de Andrade, E.T. Galvani, V.A.R. Henriques, and S.L.G. Petroni, in SAE Technical Paper 2012-36-02 (2012).

D. Eskin, S. Voropayev, and O. Vasilkov, Powder Technol. 105, 257 (1999).

H.-G. Zander, H. Bornfeld, and B.-M. Holle, US Patent 4,917,309 (1990).

ASTM E1409-13, Standard Test Method for Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by Inert Gas Fusion (West Conshohocken, PA: ASTM International, 2013). https://doi.org/10.1520/E1409-13.

X. Suo, S. Yin, M.P. Planche, T. Liu, and H. Liao, Surf. Coat. Technol. 268, 90 (2015).

E.W. Lemmon, M.O. McLinden, and D.G. Friend, in NIST Chemistry WebBook, NIST Standard Reference Database Number 69, ed. by P.J. Linstrom, W.G. Mallard (National Institute of Standards and Technology, Gaithersburg MD, 2016).

Acknowledgement

The authors acknowledge Funding support by the US Department of Energy (US DOE), Innovative Manufacturing Initiative (DEEE0005761), through the Advanced Manufacturing Office and the Office of Energy Efficiency and Renewable Energy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Dr. Pei Sun, Dr. Mark Koopman, and Dr. Z. Zak Fang are listed as inventors on the HSPT process patent (US patent no. 9816157B2).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dunstan, M.K., Simpson, B., Sun, P. et al. Effects of Process Gas Pressure and Type on Oxygen Content in Sintered Titanium Produced using Jet-Milled Titanium Hydride Powders. JOM 72, 1286–1291 (2020). https://doi.org/10.1007/s11837-020-04010-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04010-0