Abstract

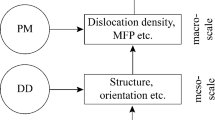

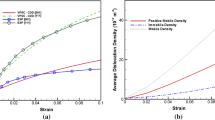

In this work, a viscoplastic fast Fourier transform (FFT)-based code is combined with a continuum dislocation dynamics (CDD) framework to analyze the mechanical behavior of polycrystalline MgAZ31 material under unidirectional tensile test. A crystal plasticity formulation including the size effects through a stress/strain gradient theory, dislocation density flux among neighboring grains and grain boundary back stress field is implemented into the CDD and coupled with VPFFT for this purpose. Then, an electron backscatter diffraction-based orientation image microscopy of a sample microstructure is applied as an input to the code. The model predicts, among other things, distributions of stress, strain, mobile dislocation density, geometrically necessary dislocation and stress–strain behavior. The numerical findings are compared with experimental results, and the micromechanical behavior of the polycrystal is discussed regarding dislocation density evaluation in different stages of strain hardening.

Similar content being viewed by others

References

M. Hamid, H. Lyu, and H. Zbib, Philos Mag 98, 2896 (2018).

C. Paramatmuni and A.K. Kanjarla, Int. J. Plast 113, 269 (2019).

M. Arul Kumar, I.J. Beyerlein, and C.N. Tomé, Acta Mater. 116, 143 (2016).

H. Wang, P.D. Wu, J. Wang, and C.N. Tomé, Int. J. Plast 49, 36 (2013).

S. Das, F. Hofmann, and E. Tarleton, Int. J. Plast 109, 18 (2018).

A.H. Kobaissy, G. Ayoub, L.S. Toth, S. Mustapha, and M. Shehadeh, Int. J. Plast 114, 252 (2018).

H. Wang, B. Clausen, C.N. Tomé, and P.D. Wu, Acta Mater. 61, 1179 (2012).

M. Ardeljan, I.J. Beyerlein, B.A. McWilliams, and M. Knezevic, Int. J. Plast 83, 90 (2016).

M. Ardeljan and M. Knezevic, Acta Mater. 157, 339 (2018).

M. Ardeljan, I.J. Beyerlein, and M. Knezevic, Int. J. Plast 99, 81 (2017).

M. Zecevic, R.A. Lebensohn, R.J. McCabe, and M. Knezevic, Int. J. Plast 109, 193 (2018).

M. Zecevic, R.A. Lebensohn, R.J. McCabe, and M. Knezevic, Acta Mater. 164, 530 (2019).

A. Eghtesad, M. Zecevic, R.A. Lebensohn, R.J. McCabe, and M. Knezevic, Comput. Mech. 61, 89 (2018).

R.A. Lebensohn, R. Brenner, O. Castelnau, and A.D. Rollett, Acta Mater. 56, 3914 (2008).

R.A. Lebensohn, E.M. Bringa, and A. Caro, Acta Mater. 55, 261 (2007).

R.A. Lebensohn and A. Needleman, J. Mech. Phys. Solids 97, 333 (2016).

R.A. Lebensohn, Acta Mater. 49, 2723 (2001).

J.C. Michel, H. Moulinec, and P. Suquet, Int. J. Numer. Meth. Eng. 52, 159 (2001).

H. Askari, J. Young, D. Field, G. Kridli, D.S. Li, and H. Zbib, Philos Mag 94, 381 (2014).

H. Moulinec and P. Suquet, Comput Method Appl M 157, 69 (1998).

J.E. Bailey and P.B. Hirsch, Philos Mag 5, 485 (1960).

E. Orowan, Proceedings of the Physical Society 52, 8 (1940).

Q. Wei, L. Kecskes, T. Jiao, K.T. Hartwig, K.T. Ramesh, and E. Ma, Acta Mater. 52, 1859 (2004).

N. Taheri-Nassaj and H.M. Zbib, Int. J. Plast 74, 1 (2015).

H. Lyu, A. Ruimi, and H.M. Zbib, Int. J. Plast 72, 44 (2015).

S. Queyreau, G. Monnet, and B. Devincre, Int. J. Plast 25, 361 (2009).

D. Terentyev, D. Bacon, and Y.N. Osetsky, J. Phys.: Condens. Matter 20, 445007 (2008).

S. Akarapu and J.P. Hirth, Acta Mater. 61, 3621 (2013).

M. Hamid, H. Lyu, B.J. Schuessler, P.C. Wo, and H.M. Zbib, Crystals 7, 152 (2017).

D.S. Li, H. Zbib, X. Sun, and M. Khaleel, Int. J. Plast 52, 3 (2014).

H.T. Zhu and H.M. Zbib, Acta Mech. 121, 165 (1997).

T. Ohashi, Int. J. Plast 21, 2071 (2005).

K. Shizawa and H.M. Zbib, Journal Of Engineering Materials And Technology-Transactions Of The Asme 121, 247 (1999).

Z. Shen, R.H. Wagoner, and W.A.T. Clark, Acta Metall. 36, 3231 (1988).

K.G. Davis, E. Teghtsoonian, and A. Lu, Acta Metall. 14, 1677 (1966).

E. Werner and W. Prantl, Acta Metall. Mater. 38, 533 (1990).

J.F. Nye, Acta Metall. 1, 153 (1953).

M.G. Armentano and R.G. Duran, Appl Numer Math 37, 397 (2001).

W.K. Liu, S.F. Li, and T. Belytschko, Comput Method Appl M 143, 113 (1997).

H. Lyu, M. Hamid, A. Ruimi, and H.M. Zbib, Int. J. Plast 97, 46 (2017).

G.D. Sim, G. Kim, S. Lavenstein, M.H. Hamza, H.D. Fan, and J.A. El-Awady, Acta Mater. 144, 11 (2018).

B. Raeisinia, S.R. Agnew, and A. Akhtar, Metallurgical and materials transactions. 42, 1418–1430 (2011).

U. Ali, Numerical Modeling of Failure in Magnesium Alloys under Axial Compression and Bending for Crashworthiness Applications. Master Thesis, University of Waterloo (2012).

Acknowledgments

The support provided by the National Science Foundation’s CMMI program to WSU under Grant No. 1434879 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hamid, M., Zbib, H.M. Dislocation Density-Based Multiscale Modeling of Deformation and Subgrain Texture in Polycrystals. JOM 71, 4136–4143 (2019). https://doi.org/10.1007/s11837-019-03744-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03744-w