Abstract

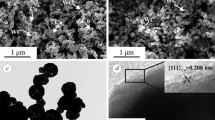

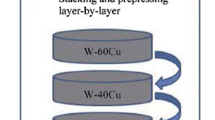

W/WC composite powders formed of WC ceramic particles dispersed on the surface of tungsten powders were fabricated by vapor deposition carbonization. Furthermore, W-30 wt.%Cu composites reinforced with WC ceramic particles were prepared by mechanical mixing, compacting, sintering, and infiltration. The microstructure, phase composition, and structure of the W/WC composite powders and the W-30 wt.%Cu composites reinforced with WC were characterized. The hardness, electrical conductivity, and arc erosion resistance of the W-30 wt.%Cu composites reinforced with WC were evaluated and compared with those of a conventional W-30 wt.%Cu composite. The results confirmed successful fabrication of the W/WC composite powders and W-30 wt.%Cu composites reinforced with WC. The hardness, electrical conductivity, and arc erosion resistance of the W-30 wt.%Cu composites reinforced with WC were dramatically enhanced due to the introduction of WC ceramic particles by vapor deposition carbonization.

Similar content being viewed by others

References

J.Q. Li, N. Deng, P. Wu, and Z.J. Zhou, J. Alloys Compd. 770, 405 (2019).

Y. Li, R.X. Liu, J. Zhang, G.Q. Luo, Q. Shen, and L.M. Zhang, Surf. Coat. Technol. 361, 302 (2019).

C.L. Zhang, Q. Gao, P. Lv, J. Cai, C.T. Peng, Y.X. Jin, and Q.F. Guan, Powder Technol. 325, 340 (2018).

E. Tejado, A.V. Müller, J.H. You, and J.Y. Pastor, Mater. Sci. Eng., A 712, 738 (2018).

M. Ahangarkani, Int. J. Refract. Met. Hard Mater. 72, 15 (2018).

B.Q. Li, Z.Q. Sun, G.L. Hou, P. Hu, and F.L. Yuan, J. Alloys Compd. 766, 204 (2018).

H. Ibrahim, A. Aziz, and A. Rahmat, Int. J. Refract. Met. Hard Mater. 43, 222 (2014).

A. Elaayed, W. Li, O.A. El Kady, W.M. Daoush, E.A. Olevsky, and R.M. German, J. Alloys Compd. 639, 373 (2015).

X. Wei, D.M. Yu, Z.B. Sun, Z.M. Yang, X.P. Song, and B.J. Ding, Vacuum 107, 83 (2014).

S.H. Liang, X.H. Wang, L.L. Wang, W.C. Cao, and Z.K. Fan, J. Alloys Compd. 516, 161 (2012).

S.N. Alam, Mater. Sci. Eng., A 433, 161 (2006).

J.L. Cabezas-Villa, L. Olmos, H.J. Vergara-Hernández, O. Jiménez, P. Garnica, D. Bouvard, and M. Flores, Trans. Nonferrous Met. Soc. China 27, 2214 (2017).

D.L. Yung, M. Antonov, R. Veinthal, and I. Hussainova, Wear 352–353, 171 (2016).

W.Q. Wang, X. Zeng, Y.L. Li, D. Wang, Y. Liu, T. Yamaguchi, K. Nishio, and J. Cao, Mater. Charact. 134, 182 (2017).

X.H. Yang, S.H. Liang, X.H. Wang, P. Xiao, and Z.K. Fan, Int. J. Refract. Met. Hard Mater. 28, 305 (2010).

Y.L. Yuan and Z.G. Li, Surf. Coat. Technol. 328, 256 (2017).

D.D. Gu, Z.Y. Wang, Y.F. Shen, Q. Li, and Y.F. Li, Appl. Surf. Sci. 255, 9230 (2009).

Q. Zhang, S.H. Liang, and L.C. Zhuo, J. Alloys Compd. 708, 796 (2017).

Q. Zhang, S.H. Liang, and L.C. Zhuo, J. Mater. Res. Technol., (2018). https://doi.org/10.1016/j.jmrt.2018.11.003.

F.N. Hao and W.H. Wu, IEEE T. El. In. 25, 557 (1990).

J. Wang, C.Y. Zhang, H. Zhang, Z.M. Yang, and B.J. Ding, Trans. Nonferrous Met. Soc. China 11, 226 (2001).

W.C. Cao, S.H. Liang, X. Zhang, X.H. Wang, and X.H. Yang, Int. J. Refract. Met. Hard Mater. 29, 237 (2011).

W.C. Cao, S.H. Liang, D.Q. Ma, X.H. Wang, and X.H. Yang, Sci. Eng. Powder Metall. 15, 350 (2010).

W.J. Yang, Arc Welding Method and Equipment, 2nd ed. (Harbin: Harbin Institute of Technology Press, 2007), pp. 10–12.

J.P. Sun, Z.X. Zhang, S.M. Hou, G.M. Zhang, X.Y. Zhao, W.M. Liu, and Z.Q. Xue, Acta Electron. Sin. 30, 655 (2002).

Acknowledgements

The authors would like to acknowledge the National Science Foundation of China (NSFC No. 51631002 and 51801151), the Key Research and Development Project of Shaanxi Province (No. 2019ZDLGY05-07 and 2017ZDXM-GY-033), and the Key Laboratory Project of Science and Technology Agency (No. 13JS075).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Q., Chen, B., Zhao, B. et al. Microstructure and Properties of W-30 wt.%Cu Composites Reinforced with WC Particles Prepared by Vapor Deposition Carbonization. JOM 71, 2541–2548 (2019). https://doi.org/10.1007/s11837-019-03520-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03520-w