Abstract

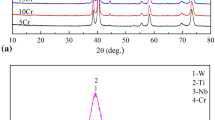

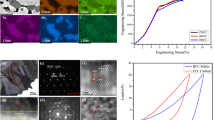

Refractory high-entropy alloys (HEAs) are reported to have better properties than conventional alloys. In this work, a new refractory WMoNbCrTi HEA was spark plasma sintered with ball milling powder. The results show that the microstructure and mechanical properties of the bulk alloys are strongly dependent on the milling duration of the powders. The structure of the powders milled for 5–40 h is mainly composed of three BCC solid solution phases (W-rich, Nb-rich and Cr-rich). After being consolidated by SPS, the structure of the bulk alloys consists of a W-rich solid solution matrix with a small amount of Ti-rich solid solution and Laves phase. The WMoNbCrTi HEA prepared from 30 h milling powder shows the highest hardness value of 10.40 GPa. However, the alloy prepared from the 5 h milling powder exhibits the maximum fracture toughness (7.16 MPa m1/2), compressive fracture strength (2765 MPa) and fracture strain (9.8%), respectively. The reasons for the influence of the milling duration on the mechanical properties of the WMoNbCrTi HEAs are discussed in detail. The combination of mechanical alloying and the subsequent sintering is a promising way to fabricate HEAs with controllable mechanical properties.

Similar content being viewed by others

References

D.B. Miracle and O.N. Senkov, Acta Mater. 122, 448 (2017).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

Z.J. Wang, S. Guo, and C.T. Liu, JOM 66, 1966 (2014).

C.M. Lin and H.L. Tsai, Intermetallics 19, 288 (2011).

A. Poulia, E. Georgatis, A. Lekatou, and A.E. Karantzalis, Int. J. Refract. Met. Hard Mater. 57, 50 (2016).

T.T. Shun, L.Y. Chang, and M.H. Shiu, Mater. Charact. 70, 63 (2012).

J. Chen, X.Y. Zhou, W.L. Wang, B. Liu, Y.K. Lv, W. Yang, D.P. Xu, and Y. Liu, J. Alloys Compd. 760, 15 (2018).

H. Chen, A. Kauffmann, B. Gorr, D. Schliephake, C. Seemüller, J.N. Wagner, and M. Heilmaier, J. Alloys Compd. 661, 206 (2016).

B. Gorr, F. Mueller, H.J. Christ, T. Mueller, H. Chen, A. Kauffmann, H.-J. Christ, and M. Heilmaier, J. Alloys Compd. 688, 468 (2016).

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miraclea, and C.F. Woodwarda, J. Alloys Compd. 509, 6043 (2011).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

C.C. Juan, M.H. Tsai, C.W. Tsai, C.M. Lin, W.R. Wang, C.C. Yang, S.K. Chen, S.J. Lin, and J.W. Yeh, Intermetallics 62, 76 (2015).

S.P. Wang and J. Xu, Mater. Sci. Eng. C 73, 80 (2017).

S. Varalakshmi, M. Kamaraj, and B.S. Murty, Mater. Sci. Eng. A 527, 1027 (2010).

D. Kumar, O. Maulik, A.S. Bagri, Y.V.S.S. Prasad, and V. Kumar, Mater. Today Proc. 3, 2926 (2016).

C. Yang, M.D. Zhu, X. Luo, L.H. Liu, W.W. Zhang, and Y. Long, Scr. Mater. 139, 96 (2017).

J.H. Yan, J.X. Huang, K.L. Li, P. Zhou, Y. Wang, and J.W. Qiu, J. Mater. Eng. Perform. 27, 6218 (2018).

D. Oleszak, A. Antolak-Dudka, and T. Kulik, Mater. Lett. 232, 160 (2018).

J.Y. Pan, T. Dai, T. Lu, X.Y. Ni, J.W. Dai, and M. Li, Mater. Sci. Eng. A 738, 362 (2018).

B. Kang, J. Lee, H.J. Ryu, and S.H. Hong, J. Alloys Compd. 767, 1012 (2018).

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall, J. Am. Ceram. Soc. 64, 533 (1981).

B. Kang, J. Lee, H.J. Ryu, and S.H. Hong, Mater. Sci. Eng. A 712, 616 (2018).

W. Ji, W.M. Wang, H. Wang, J.Y. Zhang, Y.C. Wang, F. Zhang, and Z.G. Fu, Intermetallics 56, 24 (2015).

J.B. Fogagnolo, F. Velasco, M.H. Robert, and J. Torralba, Mater. Sci. Eng. A 342, 131 (2003).

C. Suryanarayana, Prog. Mater. Sci. 46, 1 (2001).

Z.Q. Fu, W.P. Chen, Z. Chen, H.M. Wen, and E.J. Lavernia, Mater. Sci. Eng. A 619, 137 (2014).

H. Wen, Y. Zhao, Y. Liu, O. Torera, K.M. Nesterov, R.K. Islamgaliev, R.Z. Valiev, and E.J. Lavernia, Philos. Mag. 90, 4541 (2010).

H. Wen, R.K. Islamgaliev, K.M. Nesterov, R.Z. Valiev, and E.J. Lavernia, Philos. Mag. Lett. 93, 481 (2013).

W.P. Chen, Z.Q. Fu, S.C. Fang, H.Q. Xiao, and D.Z. Zhu, Mater. Des. 51, 854 (2013).

F.G. Coury, T. Butler, K. Chaput, A. Saville, J. Copley, J. Foltz, P. Mason, K. Clarke, M. Kaufman, and A. Clarke, Mater. Des. 155, 244 (2018).

M. Zhang, X. Zhou, and J. Li, J. Mater. Eng. Perform. 26, 1 (2017).

O.N. Senkov and C.F. Woodward, Mater. Sci. Eng. A 529, 311 (2011).

O.N. Senkov, S.V. Senkova, D.B. Miracle, and C. Woodward, Mater. Sci. Eng. A 565, 51 (2013).

A.J. Albaaji, E.G. Castle, M.J. Reece, J.P. Hall, and S.L. Evans, Mater. Des. 122, 296 (2017).

M. Cabeza, I. Feijoo, P. Merino, G. Pena, M.C. Péreza, and S. Cruz, Powder Technol. 321, 31 (2017).

X.R. Zhang, Z.X. Zhang, B. Nie, H.Y. Chen, Y.M. Wang, L.Y. Zheng, Y.M. Bai, and W.M. Wang, Ceram. Int. 44, 10766 (2018).

K.A. Nazari, A. Nouri, and T. Hilditch, Mater. Lett. 140, 55 (2015).

Z.D. Han, N. Chen, S.F. Zhao, L.W. Fan, G.N. Yang, Y. Shao, and K.F. Yao, Intermetallics 84, 153 (2017).

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant No. 51475161) and Hunan Provincial Natural Science Foundation of China (No. 2018 JJ2119)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yan, J., Li, K., Wang, Y. et al. Microstructure and Mechanical Properties of WMoNbCrTi HEAs Sintered from the Powders Milled for Different Durations. JOM 71, 2489–2497 (2019). https://doi.org/10.1007/s11837-019-03432-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03432-9