Abstract

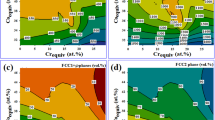

CoCrFeNiVAlx (x values in molar ratio, x = 0, 0.5, 1.0, 1.5 and 2.0, respectively) high-entropy alloys have been designed and prepared. Microstructure and mechanical properties of the CoCrFeNiVAlx alloys have been studied in as-cast conditions. The fcc (face-centered cubic structure) phase and the σ phase (intermetallic phase) have been observed in the CoCrFeNiV alloy. With the increase of Al content, the alloy structure has a tendency to change to a single stable bcc (body-centered cubic) structure. The effect of solid solution strengthening on the compressive strength of the alloy is more obvious with the addition of Al, which is the most significant in the CoCrFeNiVAl1.5 alloy. This alloy shows good comprehensive mechanical properties, i.e., the compressive strength, plasticity and microhardness reach as high as 2140 MPa, 9.5% and 684.9 HV, respectively. High-performance CoCrFeNiVAlx alloys are worth further study for applications of high-entropy alloys.

Similar content being viewed by others

References

S.Y. Chen, X. Yang, K.A. Dahmen, P.K. Liaw, and Y. Zhang, Entropy 16, 870 (2014).

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, H. Wang, Y.C. Wang, Q.J. Zhang, and J. Shi, Mater. Sci. Eng., A 508, 214 (2009).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, and Z.P. Lu, Acta Mater. 102, 187 (2016).

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov, G.A. Salishchev, and O.N. Senkov, Mater. Sci. Eng. A 533, 107 (2012).

S. Praveen, J. Basu, S. Kashyap, and R.S. Kottada, J. Alloys Compd. 662, 361 (2016).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008).

G. Sheng and C.T. Liu, Prog. Nat. Sci. Mater. Int. 21, 433 (2011).

S. Guo, C. Ng, J. Lu, and C.T. Liu, J. Appl. Phys. 109, 103505 (2011).

L. Xie, P. Brault, A.L. Thomann, X. Yang, Y. Zhang, and G.Y. Shang, Intermetallics 68, 78 (2016).

D.Y. Li and Y. Zhang, Intermetallics 70, 24 (2016).

S.Y. Chen, X. Xie, W.D. Li, R. Feng, B.L. Chen, J.W. Qiao, Y. Ren, Y. Zhang, K.A. Dahmen, and P.K. Liaw, Mater. Chem. Phys. 210, 20 (2018).

C.J. Tong, M.R. Chen, J.W. Yeh, S.J. Lin, S.K. Chen, T.T. Shun, and S.Y. Chang, Metall. Mater. Trans. A 36, 1263 (2005).

M.R. Chen, S.J. Lin, J.W. Yeh, S.K. Chen, Y.S. Huang, and C.P. Tu, Mater. Trans. 47, 1395 (2006).

M.R. Chen, S.J. Lin, J.W. Yeh, M.H. Chuang, S.K. Chen, and Y.S. Huang, Metall. Mater. Trans. A 37, 1363 (2006).

Y. Zhang, D. Pelliccia, B. Milkereit, N. Kirby, M.J. Starink, and P.A. Rometsch, Mater. Des. 142, 259 (2018).

H.M. Ye, Y.Z. Zhan, and N. Nie, Mater. Sci. Technol. 34, 952 (2018).

Y.J. Zhou, Y. Zhang, F.J. Wang, Y.L. Wang, and G.L. Chen, J. Alloys Compd. 466, 201 (2008).

Y. Zhang, X. Yang, and P.K. Liaw, JOM 64, 830 (2012).

Y. Dong, Y.P. Lu, L. Jiang, T.M. Wang, and T.J. Li, Intermetallics 52, 105 (2014).

O.N. Senkov and D.B. Miracle, Mater. Res. Bull. 36, 2183 (2001).

Acknowledgements

This research work is supported by the National Key R&D Program of China (2016YFB0301400), the National Natural Science Foundation of China (51761002), the Training Plan of High-Level Talents of Guangxi University (XMPZ160714), and the research project of Guangxi Key Laboratory of Processing for Non-ferrous Metallic and Featured Materials (GXYSSF1807).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, X., Zhan, Y. & Tang, H. Development of CoCrFeNiVAlx High-Entropy Alloys Based on Solid Solution Strengthening. JOM 71, 3473–3480 (2019). https://doi.org/10.1007/s11837-019-03416-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03416-9