Abstract

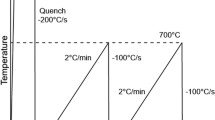

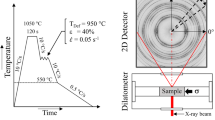

Austenite corresponds to a major constituent of carbide-free bainitic steels required to obtain enhanced deformability assisted by transformation-induced plasticity. It is, therefore, of foremost importance to retain sufficient amounts during processing and heat treatment. In order to analyze and describe the tempering reactions occurring during heating a material consisting of bainitic ferrite and C-enriched austenite, a complementary thermal analysis protocol has been applied using dilatometry and differential scanning calorimetry. Thereby, kinetic parameters were determined and interpreted in the view of literature and supporting calculations. Austenite decomposition was observed using both methods in the temperature regime of about 500°C. The reaction’s signature was revealed by calculation of the transformation enthalpy. Dilatometry suggests that decomposition of highly C-enriched austenite predominates at lower temperatures and, on further heating, regions with lower C concentrations follow. Additionally, dilatometry revealed C redistribution in bainitic ferrite already occurring at temperatures between 230°C and 330°C.

Similar content being viewed by others

Abbreviations

- a i, b θ, c θ :

-

Lattice constants (Å)

- B i :

-

High-temperature limit of thermal expansion coefficient (K−1)

- C :

-

Empirical constant

- f i, f j :

-

Phase fraction (mass or molar) (m.%, mol.%)

- H j :

-

Molar enthalpy (J/mol)

- k 0 :

-

Preexponential factor of rate constant (s−1)

- l 0 :

-

Original length (µm)

- M s :

-

Martensite start temperature (°C)

- n i :

-

Avrami exponent

- n j :

-

Molar quantity (mol)

- Q a i :

-

Actvation energy (kJ/mol)

- R :

-

Ideal gas constant (JK−1/mol)

- T :

-

Temperature (K, °C)

- t :

-

Time (s)

- T eq :

-

Equilibrium transformation temperature (°C)

- T p i :

-

Peak temperature (°C)

- w i :

-

Concentration (m.%)

- α i :

-

Conversion degree

- β :

-

Heating rate (°C/s)

- ∆l :

-

Change in length (µm)

- θ D, i :

-

Debye temperature (K)

- κ i :

-

Empirical constant (J/s)

- σ :

-

Standard deviation

References

O. Bouaziz, H. Zurob, and M. Huang, Steel Res. Int. 84, 937 (2013).

E. De Moor, and J. G. Speer, in Automot. Steels Des. Metall. Process. Appl., ed. by R. Rana, and S.B. Singh (Elsevier, Amsterdam, 2016), pp. 289–316.

L. Liu, B. He, and M.X. Huang, Adv. Eng. Mater. 20, 1701083 (2018).

P.J. Jacques, Curr. Opin. Solid State Mater. Sci. 8, 259 (2004).

F.G. Caballero, M.K. Miller, C. Garcia-Mateo, and J. Cornide, J. Alloys Compd. 577, S626 (2013).

C. Garcia-Mateo, J.A. Jimenez, H.-W. Yen, M.K. Miller, L. Morales-Rivas, M. Kuntz, S.P. Ringer, J.-R. Yang, and F.G. Caballero, Acta Mater. 91, 162 (2015).

M. Hillert, L. Höglund, and J. Ågren, Acta Metall. Mater. 41, 1951 (1993).

G. Ghosh and G.B. Olson, Acta Mater. 50, 2099 (2002).

E. Kozeschnik and H.K.D.H. Bhadeshia, Mater. Sci. Technol. 24, 343 (2008).

M.J. Peet, S.S. Babu, M.K. Miller, and H.K.D.H. Bhadeshia, Metall. Mater. Trans. A 48, 3410 (2017).

K. Zhu, C. Mager, and M. Huang, J. Mater. Sci. Technol. 32, 1475 (2017).

H.K.D.H. Bhadeshia and D.V. Edmonds, Metall. Trans. A 10, 895 (1979).

H. Chen and S. van der Zwaag, JOM 68, 1320 (2016).

L. Lan and X. Kong, JOM 70, 666 (2018).

A.S. Zav’yalov and M.I. Senchenko, Met. Sci. Heat Treat. Met. 1, 3 (1961).

G.R. Speich and W.C. Leslie, Metall. Trans. 3, 1043 (1972).

R.M. Horn and R.O. Ritchi, Metall. Trans. A 9, 1039 (1978).

F.G. Caballero, M.K. Miller, C. Garcia-Mateo, C. Capdevila, and S.S. Babu, Acta Mater. 56, 188 (2008).

A. Saha Podder and H.K.D.H. Bhadeshia, Mater. Sci. Eng. A 527, 2121 (2010).

M.A. Santajuana, R. Rementeria, M. Kuntz, J.A. Jimenez, F.G. Caballero, and C. Garcia-Mateo, Metall. Mater. Trans. A 49, 2026 (2018).

H.K.D.H. Bhadeshia, Bainite in Steels: Theory and Practice, 3rd ed. (Leeds: Maney, 2015).

S. Reisinger, G. Ressel, S. Eck, and S. Marsoner, Micron 99, 67 (2017).

J. Mahieu, J. Maki, B.C. De Cooman, and S. Claessens, Metall. Mater. Trans. A 33, 2573 (2002).

C. Hofer, F. Winkelhofer, H. Clemens, and S. Primig, Mater. Sci. Eng. A 664, 236 (2016).

S.M.C. van Bohemen, Scr. Mater. 69, 315 (2013).

S.M.C. van Bohemen, Scr. Mater. 75, 22 (2014).

R. Ruhl and M. Cohen, Trans. Met. Soc. AIME 245, 241 (1969).

S.Y.P. Allain, S. Gaudez, G. Geandier, J.C. Hell, M. Gouné, F. Danoix, M. Soler, S. Aoued, and A. Poulon-Quintin, Mater. Sci. Eng. A 710, 245 (2018).

A. Devaraj, Z. Xu, F. Abu-Farha, X. Sun, and L.G. Hector, JOM 70, 1752 (2018).

A.W. Coats and J.P. Redfern, Nature 201, 68 (1964).

K. Matusita, T. Komatsu, and R. Yokota, J. Mater. Sci. 19, 291 (1984).

J. Farjas and P. Roura, Acta Mater. 54, 5573 (2006).

E. De Moor, C. Föjer, J. Penning, A.J. Clarke, and J.G. Speer, Phys. Rev. B 82, 1 (2010).

J.A.V. Leiva, E.V. Morales, E. Villar-Cociña, C.A. Donis, and I. De, J. Mater. Sci. 45, 418 (2010).

S. Primig and H. Leitner, Thermochim. Acta 526, 111 (2011).

H.E. Kissinger, Anal. Chem. 29, 1702 (1957).

G.W.H. Höhne, W.F. Hemminger, and H.-J. Flammersheim, Differential Scanning Calorimetry, 2nd ed. (Berlin: Springer, 2003).

E.J. Seo, L. Cho, and B.C. De Cooman, Acta Mater. 107, 354 (2016).

P.V. Morra, A.J. Böttger, and E.J. Mittemeijer, J. Therm. Anal. Calorim. 64, 905 (2001).

Y. Tomita, J. Mater. Sci. 24, 731 (1989).

M. Onink, F.D. Tichelaar, C.M. Brakman, E.J. Mittemeijer, and S. van der Zwaag, Z. Met. 87, 24 (1996).

F.G. Caballero, C. García-Mateo, and C. García de Andrés, Mater. Trans. 46, 581 (2005).

S.J. Lee and Y.K. Lee, Scr. Mater. 52, 973 (2005).

Acknowledgements

The authors gratefully acknowledge the financial support under the scope of the COMET program within the K2 Center “Integrated Computational Material, Process and Product Engineering (IC-MPPE)” (Project No 859480). This program is supported by the Austrian Federal Ministries for Transport, Innovation and Technology (BMVIT) and for Digital and Economic Affairs (BMDW), represented by the Austrian research funding association (FFG), and the federal states of Styria, Upper Austria and Tyrol.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klein, T., Lukas, M., Haslberger, P. et al. Complementary Thermal Analysis Protocols for the Investigation of the Tempering Reactions of a Carbide-Free Bainitic Steel. JOM 71, 1357–1365 (2019). https://doi.org/10.1007/s11837-019-03331-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03331-z