Abstract

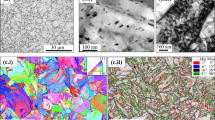

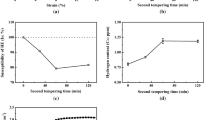

This work is aimed at studying the hydrogen–copper precipitate interaction in a martensitic steel. Analysis of hydrogen thermal desorption revealed that precipitation of copper particles enhances the hydrogen trapping capability of tempered copper-containing martensitic steel. Moreover, precipitation of copper could make hydrogen retain longer in the steel, indicating a retarded diffusion of hydrogen. Copper precipitates as a hydrogen trapping site were observed to preserve an activation energy of 35.6 kJ mol−1 by Choo-and-Lee method after release for 4 h at room temperature. This value is higher than the activation energy of dislocation. Moreover, tempered steel with copper particles displayed better resistance to hydrogen embrittlement in notched, slow-strain-rate tensile tests.

Similar content being viewed by others

References

W.H. Johnson, Proc. Roy. Soc. Lond. 23, 168 (1874).

E.M.K. Hillier and M.J. Robinson, Corros. Sci. 46, 715 (2004).

G.W. Hollenberg, E.P. Simonen, G. Kalinin, and A. Terlain, Fusion Eng. Des. 28, 190 (1995).

R.E. Melchers, Corros. Sci. 47, 2391 (2005).

G. Lovicu, M. Bottazzi, F. D’Aiuto, M. De Sanctis, A. Dimatteo, C. Santus, and R. Valentini, Metall. Mater. Trans. A 43, 4075 (2012).

A. Turnbull, Int. J. Hydrog. Energy 40, 16961 (2015).

M.L. Martin, B.P. Somerday, R.O. Ritchie, P. Sofronis, and I.M. Robertson, Acta Mater. 60, 2739 (2012).

M.L. Martin, J.A. Fenske, G.S. Liu, P. Sofronis, and I.M. Robertson, Acta Mater. 59, 1601 (2011).

H.K. Birnbaum and P. Sofronis, Mater. Sci. Eng. A 176, 12 (1994).

D.S. Shih, I.M. Robertson, and H.K. Birnbaum, Acta Metall. 36, 111 (1988).

A. Nagao, M. Dadfarnia, B.P. Somerday, P. Sofronis, and R.O. Ritchie, J. Mech. Phys. Solids 112, 403 (2018).

A.A. Barani, D. Ponge, and D. Raabe, Steel Res. Int. 77, 704 (2006).

O. Bouaziz, H. Zurob, and M. Huang, Steel Res. Int. 84, 937 (2013).

B.D. Craig and G. Krauss, Metall. Trans. A 11, 1799 (1980).

F. HajyAkbary, J. Sietsma, A.J. Bottger, and M.J. Santofimia, Mater. Sci. Eng. A 639, 208 (2015).

G. Krauss, Metall. Mater. Trans. A 32, 861 (2001).

F.-G. Wei and K. Tsuzaki, Scr. Mater. 52, 467 (2005).

X. Zhu, W. Li, T.Y. Hsu, S. Zhou, L. Wang, and X. Jin, Scr. Mater. 97, 21 (2015).

H. Asahi, D. Hirakami, and S. Yamasaki, ISIJ Int. 43, 7 (2003).

J. Lee, T. Lee, Y.J. Kwon, D.-J. Mun, J.-Y. Yoo, and C.S. Lee, Met. Mater. Int. 22, 364 (2016).

A. Nagao, M.L. Martin, M. Dadfarnia, P. Sofronis, and I.M. Robertson, Acta Mater. 74, 244 (2014).

M. Mujahid, ASM Int. 7, 11 (1998).

S. Takaki, M. Fujioka, S. Aihara, Y. Nagataki, T. Yamashita, N. Sano, Y. Adachi, M. Nomura, and H. Yaguchi, Mater. Trans. 45, 2239 (2004).

S. Komazaki, A. Koyama, and T. Misawa, Mater. Trans. 43, 2213 (2002).

E.J. Song, D.-W. Suh, and H.K.D.H. Bhadeshia, Comput. Mater. Sci. 79, 36 (2013).

M. Wang, E. Akiyama, and K. Tsuzaki, Mater. Sci. Eng. A 398, 37 (2005).

N. Maruyama, M. Sugiyama, T. Hara, and H. Tamehiro, Mater. Trans. 40, 268 (1999).

G.R. Speich and R.A. Oriani, Trans. Metall. Soc. AIME 233, 623 (1965).

H.E. Kissinger, Anal. Chem. 29, 1702 (1957).

H. Hagi and Y. Hayashi, Trans. Jpn. Inst. Met. 28, 368 (1987).

W.Y. Choo and J.Y. Lee, Metall. Trans. A A 13, 135 (1982).

J.S. Kim, Y.H. Lee, D.L. Lee, K.T. Park, and C.S. Lee, Mater. Sci. Eng. A 505, 105 (2009).

D.P. Escobar, K. Verbeken, L. Duprez, and M. Verhaege, Mater. Sci. Eng. A 551, 50 (2012).

R.L.S. Thomas, D.M. Li, R.R. Gangloff, and J.R. Scully, Metall. Mater. Trans. A 33, 1991 (2002).

G.M. Pressouyre, Metall. Trans. A 10, 1571 (1979).

K.-I. Ebihara, T. Suzudo, H. Kaburaki, K. Takai, and S. Takebayashi, ISIJ Int. 47, 1131 (2007).

H.K.D.H. Bhadeshia, ISIJ Int. 56, 24 (2016).

F.G. Wei and K. Tsuzaki, Metall. Mater. Trans. A 37A, 331 (2006).

H.M. Lee, Metall. Trans. A 7, 431 (1976).

Y. Ebisuzaki and M. O’Keeffe, Progr. Solid State Chem. 4, 187 (1967).

H. Mangnusson and K. Frisk, J. Phase Equilib. 38, 5 (2017).

Y.-S. Chen, D. Haley, S.S.A. Gerstl, A.J. London, F. Sweeney, R.A. Wepf, W.M. Rainforth, P.A.J. Bagot, and M.P. Moody, Science 355, 1196 (2017).

T. Depover and K. Verbeken, Int. J. Hydrog. Energy 43, 3050 (2018).

H.-W. Yen, M.-H. Chiang, Y.-C. Lin, D. Chen, C.-Y. Huang, and H.-C. Lin, Metals 7, 253 (2017).

Acknowledgements

The authors acknowledge the Ministry of Science and Technology of the Republic of China for providing financial support under Contract MOST-106-2628-E-002-015-MY3 and Contract MOST-106-2622-8-006-001. The authors especially thank Dr. Steve Woei Ooi at the Department of Materials Science and Metallurgy, University of Cambridge, for his technical support in TDA experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Lin, YC., Chen, D., Chiang, MH. et al. Response of Hydrogen Desorption and Hydrogen Embrittlement to Precipitation of Nanometer-Sized Copper in Tempered Martensitic Low-Carbon Steel. JOM 71, 1349–1356 (2019). https://doi.org/10.1007/s11837-019-03330-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03330-0