Abstract

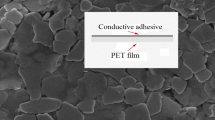

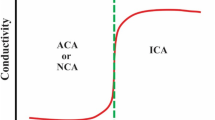

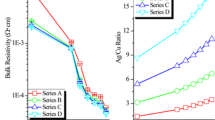

The use of electrically conductive adhesive (ECA) reduces the harm of traditional soldering technology, removes defects and improves reliability during the soldering process. ECAs are manufactured using different curing agents. The different curing agents have a strong effect on the curing temperature and reliability. Some ECAs require high temperatures for curing, which could damage temperature-sensitive components. In this article, we report on a curing agent named tetraethylenepentamine that results in a low curing temperature of silver conductive adhesive. By comparing two different curing agents, the use of tetraethylenepentamine was found to lower the curing temperature of silver conductive adhesive. Not only does this conductive adhesive have a low curing temperature, but it also can provide high electrical conductivity, matching other high-performance ECAs. Furthermore, DTA analysis also confirms that the use of tetraethylenepentamine results in a lower ECA curing temperature. The present study establishes that the use of tetraethylenepentamine could reduce the curing temperature of silver conductive adhesive, and the results are promising to minimize damage to materials and equipment.

Similar content being viewed by others

References

Y. Zemen, S.C. Schulz, H. Trommler, S.T. Buschhorn, W. Bauhofer, and K. Schulte, Sol. Energy Mat. Sol. C. 109, 155 (2013).

A.M. Gabor, M. Ralli, S. Montminy, L. Alegria, C. Bordonaro, J. Woods, L. Felton, M. Davis, B. Atchley, and T. Williams, 21st Eur. Photovolt. Sol. Energy C., Dresden (2006).

Y.S. Eom, K.S. Choi, S.H. Moon, J.H. Park, J.H. Lee, and J.T. Moon, ETRI J. 33, 864 (2011).

P. Bermel, C. Luo, L. Zeng, L.C. Kimerling, and J.D. Joannopoulos, Opt. Express 15, 16986 (2007).

A. Goetzberger, J. Luther, and G. Willeke, Sol. Energy Mat. Sol. C. 74, 1 (2002).

P.J. Ribeyron, D. Munoz, J.P. Kleider, P.R. Cabarrocas, W.V. Sark, J.K. Rath, and L. Korte, 26th Eur. Photovolt. Sol. Energy C., 853 (2011).

J. Wendt, M. Träger, M. Mette, A. Pfennig, and B. Jäckel, 24th Eur. Photovolt. Sol. Energy C., Hamburg, Germany, 3420 (2009).

Y. Zemen, T. Prewitz, T. Geipel, S. Pingel, and J. Berghold, 25th Eur. Photovolt. Sol. Energy C., Valencia, Spain, 4073 (2010).

M. Grätzel, Nat. Mat. 13, 838 (2014).

C.M. Miller, I.E. Anderson, and J.F. Smith, J. Electron. Mat. 23, 595 (1994).

H.K. Kim and F.G. Shi, Microelectron. J. 32, 315 (2001).

B.S. Yim and J.M. Kim, Microelectron. Reliab. 57, 93 (2016).

D. Wojciechowski, J. Vanfleteren, E. Reese, and H.W. Hagedorn, Microelectron. Reliab. 40, 1215 (2000).

D. Lu, Y. Sun, and C. P. Wong. W. Enc. Electr. Electron. Eng., 1 (2013).

W. Lin, X. Xi, and C. Yu, Synthetic Met. 159, 619 (2009).

C.A. Lu, P. Lin, H.C. Lin, and S.F. Wang, Jpn. J. Appl. Phys. 45, 6987 (2006).

B.S. Yim and J.M. Kim, Mater. Trans. 51, 2329 (2010).

R. Zhang, A. Dowden, H. Deng, M. Baxendale, and T. Peijs, Compos. Sci. Technol. 69, 1499 (2009).

C. Zhang, P. Wang, C.A. Ma, G.Z. Wu, and M. Sumita, Polymer 47, 466 (2006).

D. Lu, Q.K. Tong, and C.P. Wong. Proc. Int. Symp. IEEE, 2 (1999).

S. Sourour and M.R. Kamal, Thermochim. Acta 14, 41 (1976).

D. Lu and C.P. Wong, Int. J. Adhes. Adhes. 20, 189 (2000).

X. Kornmann, H. Lindberg, and L.A. Berglund, Polymer 42, 4493 (2001).

D. Ren, M. Mills, M. DeGroot, L. Clark, and S. Brown, J. Curphy. Sol. Energy Mat. Sol. C. 107, 403 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, XQ., Gan, WP., Ge, TT. et al. Effect of Tetraethylenepentamine on Silver Conductive Adhesive. JOM 70, 1800–1804 (2018). https://doi.org/10.1007/s11837-018-2939-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2939-4