Abstract

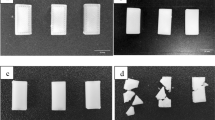

The mechanical, chemical, roughness and wettability properties of 70/30 poly (L,DL-lactide acid) three-dimensional (3D)-printed surgical plates made with extruded polymer filaments developed in the first part of this work were investigated. The plates were printed with horizontal (HRZ) and vertical (VRT) running layer orientations and evaluated by tensile, Fourier transform infrared (FTIR), optical perfilometry and wettability tests before and after degradation in simulated body fluid (SBF) for 21 days. The results show that the ultimate tensile strength (UTS) of HRZ plates before immersion in SBF was higher (34.1 MPa) than that of VRT plates (31.8 MPa). The Young’s modulus (E) of HRZ plates and VRT plates are similar (4 GPa). After immersion in SBF, the UTS of HRZ plates dropped to 20.5 MPa and E decreased to 3.3 GPa. VRT were not tested after SBF immersion due to the large degradation. FTIR analysis showed no evidence of chemical change in the plates after immersion in SBF. The roughness parameter R3z of VRT surfaces (19.54 µm) was higher than that of the HRZ surfaces (12.80 µm). The roughness parameters increased after degradation in SBF (p = 0.7048). The contact angles of HRZ surfaces before immersion in SBF (66.28°) were higher than after immersion in SBF (18.12°); the same behavior was also observed in VRT plates.

Similar content being viewed by others

References

M.R. Krijnen, M.G. Mullender, T.H. Smit, V. Everts, and P.I.J.M. Wuisman, Spine 31, 1559–1567 (2006).

T.H. Smit, T.A.P. Engels, P.I.J.M. Wuisman, and L.E. Govaert, Spine 33, 14–18 (2008).

M.S. Park, H.E. Aryan, B.M. Ozgur, R. Jandial, and W.R. Taylor, Neurosurgery 54, 631–635 (2004).

K.A. Thomas, J.M. Toth, N.R. Crawford, H.B. Seim, L.L. Shi, M.B. Harris, and A.S. Turner, Spine 33, 734–742 (2008).

P.I.J.M. Wuisman and T.H. Smit, Eur. Spine J. 15, 133–148 (2006).

A.C. Renouf-Glauser, J. Rose, D. Farrar, and R.E. Cameron, Biomaterials 26, 2415–2422 (2005).

M.J. Kaab, B.A. Rahn, A. Weiler, R. Curtis, S.M. Perren, and E. Schneider, Int J Care Injured 33, 37–42 (2002).

Y. Kang, Y. Yao, G. Yin, Z. Huang, X. Liao, X. Xu, and G. Zhao, Med. Eng. Phys. 31, 589–594 (2009).

A. Gerber and S. Gogolewski, Int J Care Injured 33, 43–57 (2002).

H. Xu, D. Han, J.-S. Dong, G.-X. Shen, G. Chai, Z.-Y. Yu, W.-J. Lang, and S.-T. Ai, Int. J. Med. Robot. Comput. Assist. Surg. 6, 66–72 (2010).

Z. Mustafa and K.E. Tanner, Composites for hard tissue repair. Wiley Encyclopedia of Composites, ed. A. Borzacchiello and L. Nicolais (New York: Wiley, 2012),

A. Butscher, M. Bohner, S. Hofmann, L. Gauckler, and R. Muller, Acta Biomater. 7, 907–920 (2011).

T. Kokubo and H. Takadama, Biomaterials 27, 2907–2915 (2006).

I. Grizzi, H. Garreau, S. Li, and M. Vert, Biomaterials 16, 305–311 (1995).

S. Li, H. Garreau, and M. Vert, Biomaterials 13, 594–600 (1992).

S. Shaffer, K. Yang, J. Vargas, M.A. Di Prima, and W. Voit, Polymer 55, 5969–5979 (2014).

D. Garlotta, J. Polym. Environ. 9, 63–84 (2002).

M. Therin and P. Christel, Biomaterials 13, 594–600 (1992).

E. Hendrick and M. Frey, J. Eng. Fib. Fab. 9, 153–164 (2014).

M.E. Rebovich, D. Vynias, and M.W. Frey, Int J Fashion Des Tech Educ 3, 129–134 (2010).

M.E.R. Coimbra, C.N. Elias, and P.G. Coelho, J. Mater. Sci. Mater. Med. 19, 3227–3234 (2008).

V. Ella, M.E. Gomes, R.L. Reis, P. Tormala, and M. Kellomaki, J. Mater. Sci. Mater. Med. 18, 1253–1261 (2007).

Acknowledgements

We thank the Carlos Chagas Foundation for Research Support from the Rio de Janeiro State (FAPERJ) and the National Council of Technological and Scientific Development from Brazilian Government (CNPq) for supporting this study via Grants: E-26/201.759/2015, E-26/201.828/2015, E-26/010.001.262/2015 and 449472-2014-0.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fernandes, D.J., Vidal, R., Assayag, A. et al. Development of 70/30 Poly-L-DL-Lactic Acid Filaments for 3D Printers (Part 2): Mechanical and Surface Properties of Bioabsorbable Printed Plates for Biomedical Applications. JOM 69, 78–83 (2017). https://doi.org/10.1007/s11837-016-2153-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-2153-1