Abstract

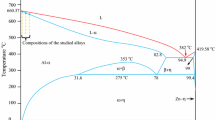

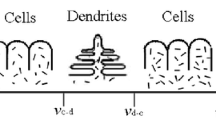

In this article, the Ni-46.1Al-7.8Mo (at.%) alloy was directionally solidified at different growth rates ranging from 15 μm/s to 1000 μm/s under a constant temperature gradient (334 K/cm). The dependence of microstructural length scales on the growth rate was investigated. The results show that, with the growth rate increasing, the primary dendritic arm spacings (PDAS) and secondary dendritic arm spacings (SDAS) decreased. There exists a large distribution range in PDAS under directional solidification conditions at a constant temperature gradient. The average PDAS and SDAS as a function of growth rate can be given as λ1 = 848.8967 V−0.4509 and λ2 = 64.2196 V−0.4140, respectively. In addition, a comparison of our results with the current theoretical models and previous experimental results has also been made.

Similar content being viewed by others

References

D. Poirier, Metall. Trans. B 18, 245 (1987).

N. Maraşlı, K. Keşlioğlu, B. Arslan, H. Kaya, and E. Çadırlı, J. Mater. Process. Technol. 202, 145 (2008).

E. Çadırlı, I. Karaca, H. Kaya, and N. Maraşlı, J. Cryst. Growth 255, 190 (2003).

G.L. Ding, W.D. Huang, X. Huang, X. Lin, and Y.H. Zhou, Acta Mater. 44, 3705 (1996).

J.A. Warren and J.S. Langer, Phys. Rev. E 47, 2702 (1993).

Y.Z. Zhou and A. Volek, Scr. Mater. 56, 537 (2007).

D. Ma, W. Xu, S.C. Ng, and Y. Li, Mater. Sci. Eng., A 390, 52 (2005).

H. Kaya, E. Çadırlı, K. Keşlioğlu, and N. Maraşlı, J. Cryst. Growth 276, 583 (2005).

J.D. Hunt, Solidification and casting of metals (London: The Metals Society, 1979), pp. 3–9.

W. Kurz and J.D. Fisher, Acta Metall. 29, 11 (1981).

R. Trivedi, Metall. Mater. Trans. A 15, 977 (1984).

J.D. Hunt and S.Z. Lu, Metall. Mater. Trans. A 27, 611 (1996).

R. Trivedi and K. Somboonsuk, Mater. Sci. Eng., A 65, 65 (1984).

D. Bouchard and J.S. Kirkaldy, Metall. Mater. Trans. B 28, 651 (1997).

M. Li, T. Mori, and H. Iwasaki, Mater. Sci. Eng., A 265, 217 (1999).

Q.Y. Pan, W.D. Huang, X. Lin, and Y.H. Zhou, J. Cryst. Growth 181, 109 (1997).

X.W. Hu, S.M. Li, W.J. Chen, S.F. Gao, L. Liu, and H.Z. Fu, J. Alloys Compd. 484, 631 (2009).

N. Maraşlı, K. Keşlioğlu, B. Arslan, H. Kaya, and E. Çadırlı, J. Mater. Process. Technol. 202, 145 (2008).

J. Feng, W.D. Huang, X. Lin, Q.Y. Pan, T. Li, and Y.H. Zhou, J. Cryst. Growth 197, 393 (1999).

G.Y. An and L.X. Liu, J. Cryst. Growth 80, 383 (1987).

J. Hui, R. Tiwari, X. Wu, S.N. Tewari, and R. Trivedi, Metall. Mater. Trans. A 33, 3499 (2002).

M. Barth, B. Wei, and D.M. Herlach, Mater. Sci. Eng., A 226–228, 770 (1997).

S.V. Raj, I.E. Locci, J.A. Salem, and R.J. Pawlik, Metall. Mater. Trans. A 33, 597 (2002).

P.L. Ferrandini, F.L.G.U. Araujo, W.W. Batista, and R. Caram, J. Cryst. Growth 275, 147 (2005).

J.F. Zhang, J. Shen, Z. Shang, L. Wang, and H.Z. Fu, Mater. Charact. 99, 160 (2015).

S.F. Gao, L. Liu, Y.K. Xu, C.B. Yang, J. Zhang, and H.Z. Fu, China Foundry 9, 160 (2012).

Z.X. Min, J. Shen, Y.L. Xiong, W. Wang, Y.J. Du, L. Liu, and H.Z. Fu, Acta Metall. Sin. 47, 397 (2011).

A.B. Kloosterman and J.T.H.M. Hosson, J. Mater. Sci. 32, 6201 (1997).

D. Ma, Y. Li, S.C. Ng, and H. Jones, Acta Metall. 48, 419 (2000).

C.M. Klaren, J.D. Verhoeven, and R. Trivedi, Metall. Trans. A 11, 1853 (1980).

H.Z. Fu, L. Liu, J.J. Guo, and J.S. Li, Directional solidification and processing of advanced materials (Beijing: Beijing Science Press, 2008), p. 687.

N. Marasli and J.D. Hunt, Acta Mater. 44, 1085 (1996).

J.Q. Li and Y.L. Tang, J. Alloys Compd. 329, 157 (2001).

E. Çadırlı, N. Maraslı, B. Bayender, and M. Gündüz, Mater. Res. Bull. 35, 985 (2000).

V. Seetharaman, L.M. Fabietti, and R. Trivedi, Metall. Trans. A 20, 2567 (1989).

C. Cicutti and R. Boeri, Scr. Mater. 45, 1455 (2001).

M. Wolf (Paper presented to the Continuous Casting, Iron and Steel Society of AIME, Varrendale, 1997, pp. 259–269).

Acknowledgements

The authors acknowledge the National Natural Science Foundation of China (No. 51564041), the Natural Science Foundation of Inner Mongolia of China (No. 2014MS0518), the Inner Mongolia University of Science and Technology Industry-Study-Research Found (No. PY201509), and the Inner Mongolia University of Science and Technology Innovation Fund (No. 2012NCL004) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Ma, X., Ren, H. et al. Influence of Growth Rate on Microstructural Length Scales in Directionally Solidified NiAl-Mo Hypo-Eutectic Alloy. JOM 68, 178–184 (2016). https://doi.org/10.1007/s11837-015-1671-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1671-6