Abstract

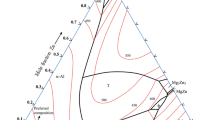

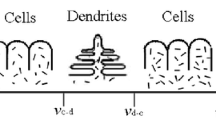

Dendritic spacing can affect microsegregation profiles and also the formation of secondary phases within interdendritic regions, which influences the mechanical properties of cast structures. To understand dendritic spacings, it is important to understand the effects of growth rate and composition on primary dendrite arm spacing (λ 1) and secondary dendrite arm spacing (λ 2). In this study, aluminum alloys with concentrations of (1, 3, and 5 wt pct) Zn were directionally solidified upwards using a Bridgman-type directional solidification apparatus under a constant temperature gradient (10.3 K/mm), resulting in a wide range of growth rates (8.3–165.0 μm/s). Microstructural parameters, λ 1 and λ 2 were measured and expressed as functions of growth rate and composition using a linear regression analysis method. The values of λ 1 and λ 2 decreased with increasing growth rates. However, the values of λ 1 increased with increasing concentration of Zn in the Al-Zn alloy, but the values of λ 2 decreased systematically with an increased Zn concentration. In addition, a transition from a cellular to a dendritic structure was observed at a relatively low growth rate (16.5 μm/s) in this study of binary alloys. The experimental results were compared with predictive theoretical models as well as experimental works for dendritic spacing.

Similar content being viewed by others

References

Y.H. Zhu: Metall. Mater. Trans. A, 2004, vol. 45, pp.3083–3097.

S. Popovié and B.Grzetz: Croat. Chem. Acta, 1999, vol. 72, pp.621– 643.

M. Hansen, (Ed.): Constitution of Binary Alloys, Mcgraw-Hill, London, 1958.

F. Gonzales and M. Rappaz: Metall. Mater. Trans. A, 2006, vol. 37, pp.2797–2806.

F. Gonzales and M. Rappaz: Metall. Mater. Trans. A, 2008, vol. 39, pp.2148–2160.

M. Rheme, F. Gonzales, and M. Rappaz: Scripta Mater., 2008, vol. 59, pp.440–443.

H. Xu, L. D. Xu, and Q. Han: Scripta Mater., 2006, vol. 54, pp.2191–2196.

K. Osamura, H. Okuda, and S. Ochicu: Scripta Metall., 1985, vol. 19, pp.1379–1384.

W. R. Osorio, J. E. Spinelli, N. Cheung, and A. Garcia: Mater. Sci. Eng. A, 2006, vol. 420, pp.179–186.

W. Cubberly and R. Bakerjian: Tool and Manufacturing Engineers Handbook, Desk Edition, Society of Manufacturing Engineers, Dearborn, Michigan, 1989.

H. S. Park, T. Kimura, T. Murakami, Y. Nagano, K. Nakata, and M. Ushio: Mater. Sci. Eng. A, 2004, vol. 371, pp.160–169.

O.V. Flores, C. Kennedy, L.E. Murr, D. Brown, S. Pappu, B.M. Nowak, and J.C. McClure: Scripta Mater., 1998, vol. 38, pp.703–708.

H. Akhyar and Husaini: Int. J. Metalcasting, 2016, vol. 10, pp. 452–56.

M.E. Glicksman and M.B. Koss: Phys. Rev. Lett., 1994, vol. 73, pp.573–576.

E. Üstün, E. Çadırlı, H. Kaya (2006) J. Phys. Condens. Matter 18, 7825–7839.

G.L. Ding, W. Huang, X. Lin, and Y. Zhou: J. Cryst. Growth, 1977, vol. 177, pp.281–288.

L. Makkonen: J. Cryst. Growth, 2000, vol. 208, pp.772–778.

E. Çadırlı, İ. Karaca, H. Kaya, and N. Maraşlı: J. Cryst. Growth, 2003, vol. 255, pp.190–203.

J.E. Spinelli, I.L. Ferreira, and A. Garcia: J. Alloys and Compd., 2004, vol. 384, pp.217–226.

M.D. Peres, C.A. Siqueira, and A. Garcia: J. Alloys and Compd., 2004, vol. 381, pp.168–181.

J.D. Hunt: Solidification and Casting of Metals, The Metal Society, London, 1979.

R. Trivedi: Metall. Trans. A, 1984, vol. 15, pp. 977–982.

W. Kurz and D.J. Fisher: Acta Metall., 1981, vol. 29, pp. 11–20.

S.Z. Lu and J.D. Hunt: Metall. Mater. Trans. A, 1996, vol. 27, pp.611–623.

D. Bouchard and J.S. Kirkaldy: Metall. Mater. Trans. B, 1996, vol. 27, pp.101–113.

D. Bouchard and J.S. Kirkaldy: Metall. Mater. Trans. B, 1997, vol. 28, pp.651–663.

T. Okamoto and K. Kishitake: J. Cryst. Growth, 1975, vol. 29, pp. 137–146.

C.T. Rios and R. Caram: J. Cryst. Growth, 1997, vol. 174, pp.65–69.

J.S. Langer and H. Müller-Krumbhaar: Acta Metall., 1978, vol. 26, pp.1681–1687.

R. Trivedi and K. Somboonsuk: Mater. Sci. Eng., 1984, vol. 65, pp.65–74.

H. Löffler(Ed.): Structure and Structure Development of Al-Zn Alloys, Akademia Verlag, Berlin, 1995.

J.M. Drezet, B. Mireux, G. Kurtuldu, O. Magdysyuk, and M. Drakopoulos: Mater. Trans. A, 2015, vol. 46, pp.4183–4190.

N.Q. Chinh, P. Jenei, J. Gubicza, E.V. Bobruk, R. Z. Valiev, and T.G. Langdon: Mater. Lett., 2017, vol. 186, pp.334–337.

C.G. Anderson, R.E. Andrews, B.G.I. Dance, M.J. Russel, E.J. Olden, and R.M. Sanderson: Proceedings of the Second International Symposium on Friction Stir Welding, Gothenburg, Sweden, 2000.

K.S. Bang, W.B. Lee, Y.M. Yeon, and S.B. Jung: International Welding/Joining Conference, Gyeongju, Korea, 2002.

P. Ravindranathan and K.C. Patil: J. Mater. Sci., 1987, vol. 22, pp.3261–3264.

F.Y. Hung, T.S.Lui, L. H. Chen, and J.G. You: J. Mater. Sci., 2007, vol. 42, pp.3865–3873.

S. Ganesan, C.L. Chan, and D.R. Poirier: Mater. Sci. Eng. A, 1992, vol. 151, pp.97–105.

M.S. Bhat, D.R. Poirier, and J.C. Heinrich: Metall. Mater. Trans. B, 1995, vol. 26, pp.1049–1056.

A. Berkdemir and M. Gündüz: App. Phys. A, 2009, vol. 96, pp.873–886.

W.R. Osorio and A. Garcia: Mater. Sci. Eng. A, 2002, vol. 325, pp.103–111.

H. Kaya, E. Çadırlı, and M. Gündüz: J. Mater. Eng. Perf., 2007, vol. 16, pp.12–21.

A. Ourdjini, J. Liu, and R. Elliott: Mat. Sci. Tech., 1994, vol. 10, pp.312–318.

H. Löffler: Structure and Structure Development in Al-Zn Alloys, Akademie Verlag, Berlin, 1995.

L. F. Mondolfo: Aluminium Alloys: Structure and Properties, Butterworths & Co. Ltd., London, 1976.

Z. Chen, Y. Mo, and Z. Nie: Metall. Mater. Trans. A, 2013, vol. 44, pp.3910–3920.

R. Trivedi and W. Kurz: Metall. Mater. Trans. A, 1990, vol. 21, pp.1311–1318.

R. Trivedi and W. Kurz: Acta Metall., 1994, vol. 42, pp. 15–23.

R. Trivedi and W. Kurz: Int. Mater. Rev., 1994, vol. 39, pp. 49–74.

S.A. David and J.M. Vitek: Int. Mater. Rev., 1989, vol. 34, pp. 213–245.

W. Kurz and D.J. Fisher: Fundamentals of Solidification, Third Edition, Trans Tech Publications, Switzerland, 1989.

S.N. Tewari and V. Laxmanan: Metall. Mater. Trans. A, 1987, vol. 18, pp.167–170.

M. Georgelin and A. Pocheau: Phys. Rev. E, 1998, vol. 57, pp.3189–3203.

S. Liu, G. Yang, L. Xiao, S. Luo, and W. Jie: JOM, 2016, vol. 68, pp. 3214–3223.

K. Wang, S. Lu, G. Mi, C. Li, and H. Fu: China Foundry, 2010, vol. 7, pp.47–51.

A.L.R. Ledesma, R.A.R. Diaz, J.C. Carvayar, O.A. Fregoso, and J.A.J. Islas: Trans. Nonferrous Met. Soc. China, 2015, vol. 25, pp. 1391−1398.

R. Trivedi, Y. Shen, and S. Liu: Metall. Mater. Trans. A, 2003, vol. 34, pp.395–401.

J. Fan, X. Li, Y. Su, R. Chen, J. Guo, and H. Fu: App. Phys. A, 2011, vol. 105, pp.239–248.

J. Lapin, L. Ondrus, and M. Nazmy: Intermetallics, 2002, vol. 10, pp.1019–1031.

J. Lapin and Z. Gabalcova: Intermetallics, 2011, vol. 19, pp.797–804.

J. Feng, W.D. Huang, X. Lin, Q.Y. Pan, T. Li, and Y.H. Zhou: J. Cryst. Growth, 1999, vol. 197, pp.393–395.

H.Y. Liu and H. Jones: J. Mater. Sci. Lett., 1992, vol. 11, pp.769–770.

H. Tunca and R.W. Smith: J. Mater. Sci., 1988, vol. 23, pp.111–120.

JE Simpson, SV Garimella, HC Groh, R Abbaschian (2001) J Heat Trans 123:990–998.

H. Ochoa, O. Fornaro, O. Bustos and B. Schulz: Int. J. Cast Met. Res., 2012, vol. 25, pp.201–206.

P.K. Rohatgi and C.M. Adams: Trans. Met. Soc. AIME, 1967, vol. 239, pp.1729–1736.

P.C. Dann, J.A. Eady, and L.M. Hogan: J. Austr. Inst. Met., 1974, vol. 19, pp. 140–147.

J.A.E. Bell and W.C. Winegard: J.Inst. Met., 1963, vol. 92, pp.357–359.

C.M. Claren, J.D. Verhoeven, and R. Trivedi: Metall. Trans. A, 1980, vol. 11, pp. 1853–1861.

B.C. Fuh: Ph.D. Thesis, Iowa, IA, 1984.

J.T. Mason, J.D. Verhoeven, and R. Trivedi: J. Cryst. Growth, 1982, vol. 59, pp. 516–524.

J.A. Juarez Islas, H. Jones, and W. Kurz: Mater. Sci. Eng., 1988, vol. 98, pp. 201–208.

T. Sivarupan, C.H. Caceres, and J.A. Taylor: Metall. Mater. Trans. A, 2013, vol. 44, pp.4071–4080.

K. P. Young and D. H. Kirkwood: Metall. Trans. A, 1975, vol. 6, pp 197–205.

M. El-Bealy and B.G. Thomas: Metall. Mater. Trans. B, 1996, vol. 27, pp.689–693.

M. Kudoh and B. Wo: Steel Res. Int., 2003, vol. 74, pp 161–167.

M. Paliwal and I.H. Jung: J. Cryst. Growth, 2014, vol. 394, pp.28–38

M.C. Flemings, T.Z. Kattamis, and B.P. Bardes: AFS Trans., 1991, vol. 99, pp. 501–506.

Acknowledgments

This project was supported by the Erciyes University Scientific Research Project Unit under Contract No: FBD-12-3978. The authors are grateful for this financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 4, 2016.

Appendices

Appendix A: λ Values Measured from Longitudinal and Transverse Sections for Al-Zn Alloys

Alloy | Al-1 Wt Pct Zn | Al-3 Wt Pct Zn | Al-5 Wt Pct Zn | |||

|---|---|---|---|---|---|---|

V (μm/s) | λ 1L (μm) | λ 1T (μm) | λ 1L (μm) | λ 1T (μm) | λ 1L (μm) | λ 1T (μm) |

8.3 | 53.2 ± 3.75 | 50.66 ± 2.29 | 62.39 ± 3.15 | 55.24 ± 2.65 | 75.72 ± 3.50 | 63.56 ± 2.85 |

16.5 | 64.40 ± 5.14 | 57.07 ± 3.49 | 70.30 ± 3.69 | 68.96 ± 2.40 | 108.25 ± 4.86 | 96.15 ± 3.89 |

41.3 | 55.61 ± 5.79 | 48.69 ± 4.27 | 63.94 ± 5.68 | 56.92 ± 3.13 | 84.91 ± 3.09 | 78.09 ± 3.01 |

82.5 | 44.98 ± 3.02 | 36.62 ± 2.45 | 48.02 ± 4.59 | 44.02 ± 2.19 | 72.84 ± 4.41 | 65.48 ± 3.23 |

165.0 | 32.49 ± 3.37 | 30.59 ± 2.33 | 44.71 ± 2.80 | 38.25 ± 2.31 | 53.14 ± 3.23 | 51.02 ± 2.39 |

Appendix B: Some Physical Properties of Al-Zn Alloy

Property | Symbol | Unit | Value | References |

|---|---|---|---|---|

Melting point | T m | K | 933 | |

Slope of liquid line | m L | K (wt pct)−1 | –2.93 | |

Diffusion coefficient (liq.) | D L | μm2 s−1 | 1200 | |

Distribution coefficient | k | 0.45 | ||

Gibbs–Thomson coefficient | Γ | μm K | 0.105 | |

The harmonic perturbations | L | mJ/m2 | 10 | |

Primary dendrite-calibrating factor | a 1 | — | 250 | |

Characteristic parameter | G oε | K/cm | 600 × 6 | |

Secondary dendrite-calibrating factor | a 2 | — | 9 |

Appendix C: Theoretical Models of λ 1 and λ 2 for the Steady-State Conditions

Theoretical Models | References |

|---|---|

\( \lambda_{1} = 2.83[m(k - 1)D\varGamma ]^{0.25} G^{ - 0.5} V^{ - 0.25} C_{\text{o}}^{0.25} \) | Hunt[21] |

\( \lambda_{1} = 2.83[m(k - 1)D\varGamma L]^{0.25} G^{ - 0.5} V^{ - 0.25} C_{\text{o}}^{0.25} \) | Trivedi[22] |

\( \lambda_{1} = 4.3[m(k - 1)D\varGamma /k^{2} ]^{0.25} G^{ - 0.5} V^{ - 0.25} C_{\text{o}}^{0.25} \) | K–F[23] |

\( \lambda_{1} = a_{1} \left( {\frac{{16G_{\text{o}} \varepsilon \varGamma D}}{m(1 - k)}} \right)^{0.5} G^{ - 0.5} V^{ - 0.5} C_{\text{o}}^{0.25} \) | |

\( \lambda_{1} = 2\varepsilon \left[ {m(k - 1)D} \right]^{0.25} G^{ - 0.5} V^{ - 0.5} C_{\text{o}}^{0.25} \) | O–K[27] |

\( \lambda_{2} = \left[ {8\varGamma DL/k\Delta T_{\text{o}} } \right]^{0.5} V^{0.5} = \lambda_{2} = \left[ { - 8\varGamma DL/mk} \right]^{0.5} V^{0.5} C_{\text{o}}^{ - 0.5} \) | T–S[30] |

\( \lambda_{2} = 2\pi a_{2} \left( {\frac{{4\sigma D^{2} }}{{(1 - k)^{2} \Delta H}}} \right)^{1/3} V^{ - 0.67} C_{\text{o}}^{ - 0.33} \) |

Rights and permissions

About this article

Cite this article

Acer, E., Çadırlı, E., Erol, H. et al. Effects of Growth Rates and Compositions on Dendrite Arm Spacings in Directionally Solidified Al-Zn Alloys. Metall Mater Trans A 48, 5911–5923 (2017). https://doi.org/10.1007/s11661-017-4337-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4337-x