Abstract

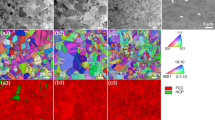

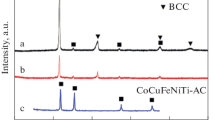

The strengthening mechanisms of Co21Cr22Cu22Fe21Ni14 multiple-principal element alloy processed by high pressure torsion (HPT) and annealing were examined. Two face-centered cubic (FCC) phases were observed in the as-cast alloy; one was a Cu-rich phase and the other was a Cu-lean one. In the HPT process, the microhardness increased from 190 HV to 470 HV at a strain of 157 due to strain hardening and grain refinement hardening. X-ray diffraction showed that the lattice parameters of the two FCC phases became closer to each other at higher HPT strain, indicating the alloying of Cu into the Cu-lean matrix. The HPT processed specimens were annealed at 500°C, 550°C, 600°C, and 650°C. The microhardness increased to 540 HV after annealing at temperatures lower than 650°C, whereas it decreased when the specimen was annealed at 650°C. The mean grain size of the specimens annealed at temperatures lower than 650°C was much smaller than 100 nm, and Cu-rich clusters with sizes ranging from 2 nm to 32 nm were distributed homogeneously. The reasons for the formation of the Cu-rich nano-clusters were discussed from a perspective of the positive mixing enthalpy of Cu in the alloy and thermalenergy for Cu diffusion at a given temperature. The dissolution and partitioning of two FCC phases played a key role in strengthening the Co21Cr22Cu22Fe21Ni14 system.

Similar content being viewed by others

References

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

J.-W. Yeh, JOM 65, 1759 (2013).

K. Zhang and Z. Fu, Intermetallics 22, 24 (2012).

M.C. Gao, JOM 66, 1964 (2014).

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, and Z.P. Lu, Scr. Mater. 68, 526 (2013).

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler, and E.P. George, Acta Mater. 61, 5743 (2013).

M.J. Yao, K.G. Pradeep, C.C. Tasan, and D. Raabe, Scr. Mater. 72–73, 5 (2014).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, Z.P. Lu, P.K. Liaw, and K.A. Dahmen, Prog. Mater. Sci. 61, 1 (2014).

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Z. Fu, Intermetallics 56, 24 (2015).

C. Zhu, Z.P. Lu, and T.G. Nieh, Acta Mater. 61, 2993 (2013).

Z. Wu, H. Bei, F. Otto, G.M. Pharr, and E.P. George, Intermetallics 46, 131 (2014).

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, and A. Hohenwarter, Acta Mater. 96, 258 (2015).

K.-Y. Tsai, M.-H. Tsai, and J.-W. Yeh, Acta Mater. 61, 4887 (2013).

M.C. Gao, JOM 65, 1749 (2013).

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008).

A. Takeuchi and A. Inoue, JIM Mater. Trans. 41, 1372 (2000).

F. Zhang and U. Kattner, J. Phase Equilib. Diffus. 36, 1 (2015).

A. Durga, K.C. Hari Kumar, and K.C. BS, Trans. Indian Inst. Met. 65, 375 (2012).

F. Zhang, C. Zhang, S.L. Chen, J. Zhu, W.S. Cao, and U.R. Kattner, CALPHAD 45, 1 (2014).

N. Park, I. Watanabe, D. Terada, Y. Yokoyama, P.K. Liaw, and N. Tsuji, Metall. Mater. Trans. A 46, 1481 (2015).

N. Park, I. Watanabe, D. Terada, Y. Yokoyama, P.K. Liaw, and N. Tsuji, Metall. Mater. Trans. A 46, 3308 (2015).

E. Botcharova, M. Heilmaier, J. Freudenberger, G. Drew, D. Kudashow, U. Martin, and L. Schultz, J. Alloys Compd. 351, 119 (2003).

C. Suryanarayana, Prog. Mater. Sci. 46, 1 (2001).

K. Uenishi, K.F. Kobayashi, K.N. Ishihara, and P.H. Shingu, Mater. Sci. Eng. A 134, 1342 (1991).

J. Xu, U. Herr, T. Klassen, and R.S. Averback, J. Appl. Phys. 79, 3935 (1996).

S. Ohsaki, S. Kato, N. Tsuji, T. Ohkubo, and K. Hono, Acta Mater. 55, 2885 (2007).

X. Sauvage, F. Wetscher, and P. Pareige, Acta Mater. 53, 2127 (2005).

Y.F. Sun, H. Fujii, T. Nakamura, N. Tsuji, D. Todaka, and M. Umemoto, Scr. Mater. 65, 489 (2011).

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Prog. Mater. Sci. 45, 103 (2000).

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, Scr. Mater. 47, 893 (2002).

J.A. Wert, X. Huang, G. Winther, W. Pantleon, and H.F. Poulsen, Mater. Today 10, 24 (2007).

S. Khamsuk, N. Park, H. Adachi, D. Terada, and N. Tsuji, J. Mater. Sci. 47, 7841 (2012).

M. Joshi, Y. Fukuta, S. Gao, N. Park, D. Terada, N. Tsuji, and I.O.P. Conf, Ser. Mater. Sci. Eng. 63, 012074 (2014).

C.-J. Tong, Y.-L. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, C.-H. Tsau, and S.-Y. Chang, Metall. Mater. Trans. A 36, 881 (2005).

Acknowledgement

This study was supported financially by the Grant-in-Aid for Scientific Research on Innovative Area, ‘‘Bulk Nanostructured Metals’’ (Area No. 2201), the Grant-in-Aid for Scientific Research (A) (No. 24246114), the Grant-in-Aid for Challenging Exploratory Research (No. 26630365), and the Elements Strategy Initiative for Structural Materials (ESISM), all through the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan (Contact No. 22102002). All the support is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Park, N., Li, X. & Tsuji, N. Microstructure and Mechanical Properties of Co21Cr22Cu22Fe21Ni14 Processed by High Pressure Torsion and Annealing. JOM 67, 2303–2309 (2015). https://doi.org/10.1007/s11837-015-1586-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1586-2