Abstract

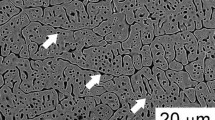

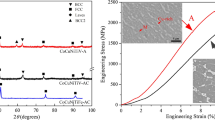

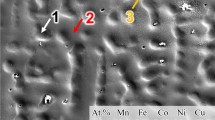

The phase components, microstructure, and compressive properties of a novel Co21Cu16Fe21Ti21V21 high entropy alloy in as-cast and annealed conditions were investigated. The phase composition in both states was composed of FCC+BCC. The BCC phase was the primary phase, and the FCC phase corresponded to Cu-rich regions. Through an annealing treatment, the yield strength, σ0.2, decreased from 1950 ± 15 MPa to 1600 ±15 MPa, but the elongation of around 13% changed slightly. In this work, the solid solution strengthening in the Cu-rich regions was deteriorated due to the ejection of the rest of principal elements via annealing, while the number of microvoids seemed to be decreased against those in the as-cast alloy. The combination of both factors simultaneously takes responsibility for the decreased strength and the enhanced elongation.

Similar content being viewed by others

REFERENCES

Y. Zhang, X. Yang, and P.K. Liaw, “Alloy design and properties optimization of high-entropy alloys,” JOM 64 (7), 830–838 (2012).

Y. Dong, Y. Lu, J. Kong, et al., “Microstructure and mechanical properties of multi-component AlCrFeNiMox high-entropy alloys,” J. Alloys Compd. 573, 96–101 (2013).

B. Gludovatz, A. Hohenwarter, D. Catoor, et al., “A fracture-resistant high-entropy alloy for cryogenic applications,” Science 345 (6201), 1153–1158 (2014).

J. W. Qiao, H. L. Jia, and P. K. Liaw, “Metallic glass matrix composites,” Mater. Sci. Eng., R 100, 1–69 (2016).

Y. Zhang, T. T. Zuo, Z. Tang, et al., “Microstructures and properties of high-entropy alloys,” Prog. Mater Sci. 61, 1–93 (2014).

J. W. Yeh, S. K. Chen, S. J. Lin, et al., “Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes,” Adv. Eng. Mater. 6, 299–303 (2004).

B. Cantor, I. T. H. Chang, P. Knight, et al., “Microstructural development in equiatomic multicomponent alloys,” Mater. Sci. Eng., A 375–377, 213–218 (2004).

S. Yoshida, T. Ikeuchi, T. Bhattacharjee, et al., “Effect of elemental combination on friction stress and Hall–Petch relationship in face-centered cubic high/medium entropy alloys,” Acta Mater. 171, 201–215 (2019).

D. B. Miracle and O. N. Senkov, “A critical review of high entropy alloys and related concepts,” Acta Mater. 122, 448-511 (2017).

M. H. Tsai and J. W. Yeh, “High-entropy alloys: a critical review,” Mater. Res. Lett. 2 (3), 107–123 (2014).

R. R. Eleti, T. Bhattacharjee, A. Shibata, et al., “Unique deformation behavior and microstructure evolution in high temperature processing of HfNbTaTiZr refractory high entropy alloy,” Acta Mater. 171, 132–145 (2019).

J. Li, Q. Fang, B. Liu, et al., “Transformation induced softening and plasticity in high entropy alloys,” Acta Mater. 147, 35–41 (2018).

I. Basu, V. Ocelik, and J. T. M. De Hosson, “Size dependent plasticity and damage response in multiphase body centered cubic high entropy alloys,” Acta Mater. 150, 104–116 (2018).

K. F. Quiambao, S. J. McDonnell, D. K. Schreiber, et al., “Passivation of a corrosion resistant high entropy alloy in non-oxidizing sulfate solutions,” Acta Mater. 164, 362–376 (2019).

M. V. Ivchenko, V. G. Pushin, A. N. Uksusnikov, and N. Wanderka, “Microstructure features of high-entropy equiatomic cast AlCrFeCoNiCu alloys,” Phys. Met. Metallogr. 114, 514–520 (2013).

M. V. Ivchenko, V. G. Pushin, A. N. Uksusnikov, N. Wanderka, and N. I. Kourov, “Specific features of cast high-entropy AlCrFeCoNiCu alloys produced by ultrarapid quenching from the melt,” Phys. Met. Metallogr. 114, 503–513 (2013).

J. W. Yeh, S. K. Chen, J. Y. Gan, et al., “Formation of simple crystal structures in Cu–Co–Ni–Cr–Al–Fe–Ti–V alloys with multiprincipal metallic elements,” Metall. Mater. Trans. A 35, 2533–2536 (2004).

C. J. Tong, M. R. Chen, S. K. Chen, et al., “Mechanical performance of the AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements,” Metall. Mater. Trans. A 36, 1263–1271 (2004).

K. B. Zhang, Z. Y. Fu, J. Y. Zhang, et al., “Microstructure and mechanical properties of CoCrFeNiTiAlx high-entropy alloys,” Mater. Sci. Eng., A 508 (1–2), 214–219 (2009).

N. D. Stepanov, D. G. Shaysultanov, G. A. Salishchev, et al., “Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys,” J. Alloys Compd. 628, 170–185 (2015).

X. Wang, H. Xie, L. Jia, et al., “Effect of Ti, Al and Cu addition on structural evolution and phase constitution of FeCoNi system equimolar alloys,” Mater. Sci. Forum 724, 335–338 (2012).

S. Singh, N. Wanderka, B. S. Murty, et al., “Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy,” Acta Mater. 59 (1), 182–190 (2011).

S. Praveen, B. S. Murty, and R. S. Kottada, “Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys,” Mater. Sci. Eng., A 534, 83–89 (2012).

M. H. Tsai, H. Yuan, G. Cheng, et al., “Morphology, structure and composition of precipitates in Al0.3CoCrCu0.5FeNi high-entropy alloy,” Intermetallics 32, 329–336 (2013).

L. Liu, J. B. Zhu, C. Zhang, et al., “Microstructure and the properties of FeCoCuNiSnx high entropy alloys,” Mater. Sci. Eng., A 548, 64–68 (2012).

L. Liu, J. B. Zhu, L. Li, et al., “Microstructure and tensile properties of FeMnNiCuCoSnx high entropy alloys,” Mater. Des. 44, 223–227 (2013).

S. Samal, S. Mohanty, A. K. Misra, et al., “Mechanical behavior of novel suction cast Ti–Cu–Fe–Co–Ni high entropy alloys,” Mater. Sci. Forum 790–791, 503–508 (2014).

Y. Lederer, C. Toher, K. S. Vecchio, et al., “The search for high entropy alloys: a high-throughput ab-initio approach,” Acta Mater. 159, 364–383 (2018).

X.F. Wang, Y. Zhang, Y. Qiao, et al., “Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys,” Intermetallics 15 (3), 357–362 (2007).

Z. Hu, Y. Zhan, G. Zhang, et al., “Effect of rare earth Y addition on the microstructure and mechanical properties of high entropy AlCoCrCuNiTi alloys,” Mater. Des. 31 (3), 1599–1602 (2010).

S. Varalakshmi, M. Kamaraj, and B. S. Murty, “Processing and properties of nanocrystalline CuNiCoZnAlTi high entropy alloys by mechanical alloying,” Mater. Sci. Eng., A 527 (4–5), 1027–1030 (2010).

Funding

Financial support from Natural Science Foundation of Jiangsu Province of China (grant no. BK20181047) is pleased to acknowledge.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, J.J., Yang, L., Xu, M.Q. et al. Microstructure and Compressive Properties of Co21Cu16Fe21Ti21V21 High Entropy Alloy. Phys. Metals Metallogr. 122, 1319–1325 (2021). https://doi.org/10.1134/S0031918X2113010X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X2113010X