Abstract

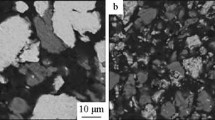

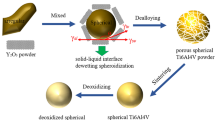

High-Nb-containing TiAl alloys are a new generation of materials for high-temperature structural applications because of their superior high-temperature mechanical properties. The alloy powders can be widely used for additive manufacturing, thermal spraying, and powder metallurgy. Because of the difficulty of making microfine spherical alloy powders in quantity by conventional techniques, a compact method was proposed, which consisted of two-step ball milling of elemental powders and subsequent radio frequency (RF) argon plasma spheroidization. In comparison with conventional mechanical alloying techniques, the two-step milling process can be used to prepare alloy powders with uniform scale in a short milling time with no addition of process control agent. This makes the process effective and less contaminating. After RF argon plasma spheroidization, the powders produced exhibit good sphericity, and the number-average diameter is about 8.2 μm with a symmetric unimodal particle size distribution. The powders perform high composition homogeneity and contain predominately supersaturated α 2-Ti3Al phase. The oxygen and carbon contents of the spheroidized powder are 0.47% and 0.050%, respectively.

Similar content being viewed by others

References

Y.W. Kim and S.L. Kim, Intermetallics 53, 92 (2014).

R. Pflumm, et al., Intermetallics 53, 45 (2014).

S. Shu, et al., J. Alloys Compd. 617, 302 (2014).

Z.C. Liu, et al., Intermetallics 10, 653 (2002).

L.L. Xiang, et al., Intermetallics 27, 6 (2012).

G.E. Bean, M.S. Kesler, and M.V. Manuel, J. Alloys Compd. 613, 351 (2014).

S. Tian, et al., Mater. Sci. Eng. A 614, 338 (2014).

L.L. Zhao, et al., Intermetallics 18, 1586 (2010).

S.H. Khajavi, J. Partanen, and J. Holmström, Comput. Ind. 65, 50 (2014).

F.P.W. Melchels, et al., Prog. Polym. Sci. 37, 1079 (2012).

S. Mellor, L. Hao, and D. Zhang, Int. J. Prod. Econ. 149, 194 (2014).

D.T. Chou, et al., Acta Biomater. 9, 8593 (2013).

S. Palanivel, et al., Mater. Des. 65, 934 (2015).

H.P. Shao, et al., Int. J. Miner. Metall. Mater. 20, 1076 (2013).

H.M. Zhang, et al., Mater. Sci. Eng. A 526, 31 (2009).

R. Gerling, et al., Mater. Sci. Eng. A 252, 239 (1998).

G. Wegmann, R. Gerling, and F.P. Schimansky, Acta Mater. 51, 741 (2003).

M.R. Farhang, A.R. Kamali, and M. Nazarian-Samani, Mater. Sci. Eng. B 168, 136 (2010).

N. Forouzanmehr, F. Karimzadeh, and M.H. Enayati, J. Alloys Compd. 471, 93 (2009).

S. Kumaran, et al., Powder Technol. 185, 124 (2008).

F. Bourg, et al., Sol. Energy Mater. Sol. Cell 72, 361 (2002).

R. Ye, P. Proulx, and M.I. Boulos, Int. J. Heat Mass Trans. 42, 1585 (1999).

M.M. Hossain, et al., Chem. Eng. J. 150, 561 (2009).

Y.W. Sheng, et al., Proc. Eng. 36, 299 (2012).

S. Kumar, et al., Mater. Sci. Eng. A 486, 287 (2008).

Z. Károly, J. Szépvölgyi, and Z. Farkas, Powder Technol. 110, 169 (2000).

V. Chaturvedi, et al., Ceram. Int. 40, 8273 (2014).

X. Lu, L.P. Zhu, and X.H. Qu, Key Eng. Mater. 520, 111 (2012).

G. Soucy, et al., Mater. Sci. Eng. A 300, 226 (2001).

Y.H. Wang, et al., Trans. Nonferr. Met. Soc. 16, 853 (2006).

Acknowledgements

This research was sponsored by the National Natural Science Foundation of China (No. 51204015) and Aeronautical Science Foundation of China (No. 2013ZE74004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tong, J.B., Lu, X., Liu, C.C. et al. Compact Process for the Preparation of Microfine Spherical High-Niobium-Containing TiAl Alloy Powders. JOM 67, 573–579 (2015). https://doi.org/10.1007/s11837-015-1303-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1303-1