Abstract

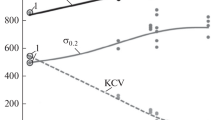

Lightweight advanced high strength steels (AHSS) with aluminum contents between 4 and 12 weight percent have been the subject of intense interest in the last decade because of an excellent combination of high strain rate toughness coupled with up to a 17% reduction in density. Fully austenitic cast steels with a nominal composition of Fe-30%Mn-9%Al-0.9%C are almost 15% less dense than quenched and tempered Cr-Mo steels (SAE 4130) with equivalent strengths and dynamic fracture toughness. This article serves as a review of the tensile and high-strain-rate fracture properties associated mainly with silicon additions to this base composition. In the solution-treated condition, cast steels have high work-hardening rates with elongations up to 64%, room-temperature Charpy V-notch (CVN) impact energies up to 200 J, and dynamic fracture toughness over 700 kJ/m2. Silicon additions in the range of 0.59–1.56% Si have no significant effect on the mechanical properties of solution-treated steels but increased the tensile strength and hardness during aging. For steels aged at 530°C to an average hardness of 310 Brinell hardness number, HBW, increasing the amount of silicon from 1.07% to 1.56% decreased the room temperature CVN breaking energy from 92 J to 68 J and the dynamic fracture toughness from 376 kJ/m2 to 265 kJ/m2. Notch toughness is a strong function of phosphorus content, decreasing the solution-treated CVN impact toughness from 200 J in a 0.006% P steel to 28 J in a 0.07% P steel. For age-hardened steels with 1% Si, increasing levels of phosphorus from 0.001% to 0.043% decreased the dynamic fracture toughness from 376 kJ/m2 to 100 kJ/m2.

Similar content being viewed by others

References

R. Hadfield and T.H. Burnham, Special Steels, 2nd ed. (New York: The Pitman Press, 1933), p. 100.

R.A. Howell, S.L. Lekakh, D.C. Van Aken, and V.L. Richards, Am. Foundry Soc. 116, 867 (2008).

G. Frommeyer and U. Brux, Steel Res. Int. 77, 627 (2006).

G.L. Kayak, Metall. Sci. Heat Trans. 11, 95 (1969).

W.K. Choo and J.H. Kim, Proceedings of the International Conference on Thermomechanical Processing of Steels and other Materials (THERMEC’97) (Warrendale, PA: TMS, 1997), pp. 1631–1637.

K. Sato, K. Tagawa, and Y. Inoue, Metall. Trans. A 21A, 5 (1990).

I. Kalashnikov, O. Acselrad, A. Shalkevich, L. Chumokova, and L. Pereira, J. Mater. Process. Tech. 136, 72 (2003).

Y. Sutou, N. Kamiya, R. Umino, I. Ohnuma, and K. Ishida, ISIJ Int. 50, 893 (2010).

O. Acselrad, L. Pereira, and M. Amaral, The Processing, Properties and Applications of Metallic and Ceramic Materials, ed. M.H. Loretto, C.J. Beevers (Birmingham, U.K., MCE Publications, 1992), pp. 829–834.

R.A. Howell, T. Weerasooriya, and D. Van Aken, Trans. Am. F 117, 751 (2009).

L. Bartlett, R.A. Howell, A. Schulte, D. Van Aken, and K. Peaslee, Proc. Materials Science and Technology Conference (Warrendale, PA: TMS, 2010), pp. 1941–1953.

D. Van Aken, R. Howell, L. Bartlett, A. Schulte, S. Lekakh, J. Medvedeva, V. Richards, and K. Peaslee (Paper presented at the 63rd Technical and Operating Conference of the Steel Founders Society of America, Chicago, IL, December 2009), paper 3-2, SFSA.

R.A. Howell (Ph.D. Dissertation, Missouri University of Science and Technology, 2009).

S.A. Buckholz, D.C. Van Aken, and L.N. Bartlett, Trans. Am. F 121, 495 (2013).

O. Acselrad, A. Souza, I. Kalashnikov, and S. Camargo, Wear 257, 99 (2004).

L. Bartlett, D. Van Aken, K. Peaslee, and R. Howell, Trans. Am. F 118, 413 (2010).

O. Acselrad, I. Kalashnikov, E. Silva, R. Simao, C. Achete, and L. Pereira, Metall. Mater. Trans. A 33A, 3569 (2002).

L.N. Bartlett, D.C. Van Aken, J. Medvedeva, D. Isheim, N. Medvedeva, and K. Song, Metall. Mater. Trans. A 45, 2421 (2014).

A. Schulte, S. Lekakh, D. Van Aken, and V.L. Richards, Trans. Am. F 118, 451 (2010).

G. Hale and A. Baker, Proceedings of the International Conference on Alternate Alloying for Environmental Resistance, ed. G.R. Smolik and S.K. Banerji (Warrendale, PA: The Metallurgical Society, Inc., 1986), pp. 67–89.

K. Sato, Y. Igarashi, Y. Inoue, T. Yamazaki, and M. Yamanaka, Proc. Int. Conf. on Stainless Steels, vol. 1 (Chiba, Japan: The Iron and Steel Institute of Japan, 1991), p. 503.

W.K. Choo and J.H. Kim, Int. Conf. on Thermomechanical Processing of Steels and Other Materials (THERMEC’97), ed. T. Chandra and T. Sakai (Warrendale, PA: TMS, 1997), pp. 1631–1637

K.H. Han, J.C. Yoon, and W.K. Choo, Scripta Mater. 20, 33 (1986).

O. Acselrad, I.S. Kalashnikov, E.M. Silva, M.S. Khadyev, and R.A. Simao, Metall. Sci. Heat Treat. 48, 543 (2006).

K. Sato, K. Tagawa, and Inoue, Mater. Sci. Eng., A 111, 45 (1989).

K.H. Han, W.K. Choo, D.Y. Choi, and S.P. Hong, Alternate Alloying for Environmental Resistance, ed. G.R. Smolik and S.K. Banerji (Warrendale, PA: The Metallurgical Society, Inc., 1987), pp. 91–106.

W. Choo, J. Kim, and J. Yoon, Acta Mater. 45, 4877 (1997).

M. Kato, T. Mori, and L. Schwartz, Acta Metall. Mater. 28, 285 (1980).

N.I. Medvedeva, R.A. Howell, D.C. Van Aken, and J.E. Medvedeva, Phys. Rev. B 81, 012105 (2010).

L.N. Bartlett, D.C. Van Aken, J. Medvedeva, D. Isheim, N. Medvedeva, and K. Song, Metall. Mater. Trans. A (2013, under review).

N.I. Medvedeva, M.S. Park, D.C. Van Aken, and J.E. Medvedeva, J. Alloy. Compd. 582, 475 (2013).

R. Howell, J. Montgomery, and D. Van Aken, AIST Trans. 6, 168 (2009).

R. Howell, S. Lekakh, and D. Van Aken, AISTech 2009 Proc. Vol. II, (Warrendale, PA: AIST, 2009), pp. 681–698.

Y. Dastur and W. Leslie, Metall. Trans. A 12, 749 (1981).

N.I. Medvedeva, D.C. Van Aken, and J.E. Medvedeva, J. Phys.-Condens. Matter. 22, 316002 (2010).

E.G. Astafurova and Y. Chumlyakov, Russ. Metall. 2010, 857 (2010).

B. Hwang and S. Kim, Mater. Sci. Eng., A 531, 182 (2012).

Y. Tomota, Y. Xia, and K. Inoue, Acta Mater. 46, 1577 (1998).

Y. Tomota and S. Endo, ISIJ Int. 30, 656 (1990).

O. Acselrad, J. Dille, L.C. Pereira, and J. Delplancke, Metall. Mater. Trans. A 35A, 3863 (2004).

T.L. Anderson, Fracture Mechanics: Fundamentals and Applications, 3rd ed. (New York: Taylor and Francis, 2005).

ASTM E 1820-08, Standard Test Method for Measurement of Fracture Toughness, 2008.

H.J. Schindler, Mechanisms and Mechanics of Damage and Failure: proceedings of the 11th ECF, ed. J. Petit (Birchwood Park, U.K.: EMAS Publishing, 1996), pp. 2007–2012.

ASTM E813-89, Standard Test Method for Jic, a Measure of Fracture Toughness, 1989.

L.N. Bartlett, A. Dash, D.C. Van Aken, V.L. Richards, and K.D. Peaslee, Int. J. Metall. 7, 17 (2013).

Acknowledgements

This work was supported in part by Army Research Laboratory under contracts from Battelle Memorial Institute (contract W911NF-07-D-0001) and Benet Laboratories (contract W15QKN-07-2-0004) and by the National Science Foundation’s MRSEC program (DMR-0520513) and made use of its Shared Facilities at the Materials Research Center of Northwestern University. The FEI Tecnai F20 scanning/transmission electron microscope was obtained with a Major Research Instrumentation grant from NSF under contract DMR-0922851. The authors also gratefully acknowledge Waukesha Foundry, Inc. for providing the low-phosphorous Fe-Mn-Al-C alloys and the alloys with varying Si content. The local-electrode atom-probe tomograph at the Northwestern University Center for Atom-Probe Tomography (NUCAPT) was purchased and upgraded with funding from NSF-MRI (DMR-0420532) and ONR-DURIP (N00014-0400798, N00014-0610539, and N00014-0910781) grants. Additional instrumentation at NUCAPT was supported by the Initiative for Sustainability and Energy at Northwestern (ISEN). The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the U.S. government. The U.S. government is authorized to reproduce and distribute reprints for government purposes notwithstanding any copyright notation herein.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bartlett, L., Van Aken, D. High Manganese and Aluminum Steels for the Military and Transportation Industry. JOM 66, 1770–1784 (2014). https://doi.org/10.1007/s11837-014-1068-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1068-y