Abstract

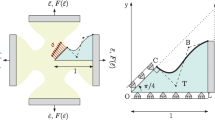

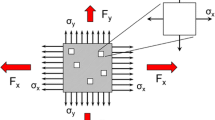

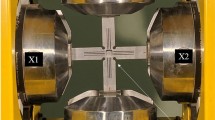

A custom biaxial testing fixture was used to evaluate new cruciform geometries. Specimens consisting of AA5083, Mg AZ31B, and TWIP steel were quasi-statically deformed to failure at 300oC. We elucidate geometric differences between specimens that accumulate plastic deformation within their gauge areas and those that prematurely fracture. Strain fields are computed with digital image correlation for selected geometries.

Similar content being viewed by others

References

J.A. Lund and J.P. Byrne, “Leonardo Da Vinci’s Tensile Strength Tests: Implications for the Discovery of Engineering Mechanics,” Civil Eng. and Env. Syst., 00 (2000), pp. 1–8.

D.S. Gianola and C. Eberl, “Micro- and Nanoscale Tensile Testing of Materials,” JOM, 61(3) (2009), pp. 24–35.

T. Foecke, S.W. Banovic, and R.J. Fields, “Sheet Metal Formability Studies at the National Institute of Standards and Technology,” JOM, 53(2) (2001), pp. 27–30.

W.F. Hosford and J.L. Duncan, “Sheet Metal Forming: A Review,” JOM, 51(11) (1999), pp. 39–44.

J.L. Duncan, J. Hu, and Z. Marciniak, Mechanics of Sheet Metal Forming, Second Edition (Woburn, MA: Butterworth-Heinemann, 2002).

E. Taleff et al., “The Effect of Stress State on High Temperature Deformation of Fine-Grained AA5083 Sheet,” Acta Materialia, 57 (2009), pp. 2812–2822.

Y. Yu, M. Wan, and X. Zhou, “Design of a Cruciform Biaxial Tensile Specimen for Limit Strain Analysis by FEM,” J. Materials Processing Technology, 123 (2002), pp. 67–70.

T. Naka et al., “Effects of Temperature on Yield Locus for 5083 Aluminum Alloy Sheet,” J. Materials Processing Technology, 140 (2003), pp. 494–499.

Standard Test Methods for Tension Testing of Metallic Materials, Designation E 8/E 8M (ASTM, 100 Barr Harbor Drive, P.O. Box C700, West Conshohocken, PA, 19428-2959).

A. Samir et al., “Service-Type Creep-Fatigue Experiments with Cruciform Specimens and Modelling of Deformation,” International Journal of Fatigue, 28 (2006), pp. 643–651.

C. Doudard et al., “Determination of an HCF Criterion by Thermal Measurements under Biaxial Cyclic Loading,” International Journal of Fatigue, 29 (2007), pp. 748–757.

A. Makinde, L. Thibodeau, and K.W. Neale, “Development of an Apparatus for Biaxial Testing using Cruciform Specimens,” Experimental Mechanics, 32(2) (1992), pp. 138–144.

T. Kuwabara, S. Ikeda, and K. Kuroda, “Measurement and Analysis of Differential Work Hardening in Cold-Rolled Steel Sheet under Biaxial Tension,” J. Materials Processing Technology, 80–81 (1998), pp. 517–523.

D. Banabic et al., “Description of Anisotropic Behaviour of AA3103-0 Aluminium Alloy Using Two Recent Yield Criteria,” Journal De Physique. IV: JP, 105 (2003), pp. 297–304.

D. Banabic et al., “An Improved Analytical Description of Orthotropy in Metallic Sheets,” International Journal of Plasticity, 21 (2005), pp. 493–512.

M. Geiger et al., “Novel Concept of Experimental Setup for Characterization of Plastic Yielding of Sheet Metal at Elevated Temperatures,” Advanced Materials Research, 6–8 (2005), pp. 657–664.

M. Geiger et al., “Experimental Determination of Yield Loci for Magnesium Alloy AZ31 under Biaxial Tensile Stress Conditions at Elevated Temperatures,” J. Product Engineering, 2(3) (2008), pp. 303–310.

A. Ghiotti, S. Bruschi, and P. Bariani, “Determination of Yield Locus of Sheet Metal at Elevated Temperatures: A Novel Concept for Experimental Setup,” Key Engineering Materials, 344 (2007), pp. 97–104.

P. Krajewski and J. Schroth, “Overview of Quick Plastic Forming,” Mat. Sci. Forum, 551–552 (2007), pp. 3–12.

T. Kuwabara et al., “Modeling Anisotropic Behavior for Steel Sheets Using Different Yield Criteria,” Key Engineering Materials, 233–236 (2003), pp. 841–846.

M. Merklein, W. Hußnätter, and M. Geiger, “Characterization of Yielding Behavior of Sheet Metal under Biaxial Stress Condition at Elevated Temperatures,” CIRP Annals—Manufacturing Technology, 57 (2008), pp. 267–274.

W. Müller, “Beitrag zur Charakterisierung von Blechwerkstoffen unter zweiachsiger Beanspruchung” (Ph.D. Thesis, University of Stuttgart, Springer-Verlag, 1996).

W. Müller and K. Pöhlandt, “New Experiments for Determining Yield Loci of Sheet Metal,” J. Materials Processing Technology, 60 (1996), pp. 643–648.

D. Green et al., “Experimental Investigation of the Biaxial Behavior of an Aluminum Sheet,” International Journal of Plasticity, 20 (2004), pp. 1677–1706.

J. Gozzi, A. Olsson, and O. Lagerqvist, “Experimental Investigation of the Behavior of Extra High Strength Steel,” Experimental Mechanics, 45(6) (2005), pp. 533–540.

S. Moondra and B. Kinsey, “Determination of Cruciform Specimen for Stress Based Failure Criterion,” Transactions of the NAMRI, 32 (2004), pp. 247–254.

Wolfgang Hußnätter, “Detection of Real Plastification in a Biaxial Tension Test,” Key Engineering Materials, 344 (2007), pp. 105–112.

T. Naka et al., “Effects of Strain Rate, Temperature and Sheet Thickness on Yield Locus of AZ31 Magnesium Alloy Sheet,” J. Materials Processing Technology, 201 (2008), pp. 395–400.

F. Abu-Farha and M. Khraisheh, “Uniaxially-Driven Controlled Biaxial Testing Fixture” (U.S. patent application pending, filed May 2008).

K. Siegert and S. Jäger, “Warm Forming of Magnesium Sheet Metal” (Warrendale, PA: Society of Automotive Engineers, 2004), Paper 2004-01-1043.

“Elektron AZ31B Sheet, Plate & Coil, Data Sheet: 482” (Magnesium Elektron UK, P.O. Box 23, Rake Lane, Swinton, Manchester, M27 8DD, England).

P. Zavattieri et al., “Spatio-temporal Characteristics of the Portevin-Le Chatelier Effect in Austenitic Steel with Twinning Induced Plasticity,” Int. J. Plasticity (2009), published on-line doi:10.1016/j.ijplas.2009.02.008.

P.A. Sherek, “Simulation and Experimental Investigation of Hot Gas-Pressure Forming for Light-Alloy Sheet Material” (M.S. Thesis, Mech. Eng. Dept. University of Texas-Austin, 2009).

T. Hong et al., “Time-resolved Strain Measurements of Portevin-Le Chatelier Bands in Aluminum using a High Speed Digital Camera,” Scripta Mat., 53 (2005), pp. 87–92.

V. Savic, L.G. Hector, Jr., and J.R. Fekete, “Digital Image Correlation Study of Plastic Deformation and Fracture in Fully Martensitic Steels,” Exp. Mech. (2008), published on-line, doi: 10.1007/s11340-008-9185-6.

W. Tong et al., “Deformation and Fracture of Miniature Tensile Bars with Resistance Spot Weld Microstructures: An Application of Digital Image Correlation to Dual-phase Steels,” Met. Mat. Trans., A 36 (2005), pp. 2651–2669.

W. Tong et al., “Local Plastic Deformation and Failure Behavior of ND:YAG Laser Welded AA5182-O and AA6111-T4 Aluminum Sheet Metals,” Metall. Mater. Trans., 38A (2007), pp. 3063–3086.

W. Tong, “An Evaluation of Digital Image Correlation Criteria for Strain Mapping Applications,” Strain, 41 (2005), pp. 167–175.

M. Sutton et al., “Effect of Subpixel Image Restoration on Digital Correlation Error Estimates,” Opt. Eng., 27 (1998), pp. 870–877.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abu-Farha, F., Hector, L.G. & Khraisheh, M. Cruciform-shaped specimens for elevated temperature biaxial testing of lightweight materials. JOM 61, 48–56 (2009). https://doi.org/10.1007/s11837-009-0121-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-009-0121-8