Abstract

Lithium-sulfur (Li–S) batteries are considered the next generation of lithium-ion batteries due to their high energy density, but they face challenges in operation under lean electrolyte conditions. Among the potential strategies, highly solvating electrolytes (HSEs) have become a prominent option. These electrolytes offer strong solvation of polysulfide intermediates, leading to modified sulfur reaction pathways and deposition morphologies compared to conventional electrolytes. This review presents a comprehensive summary of HSEs in Li–S batteries, with a focus on their development and optimization for broad applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

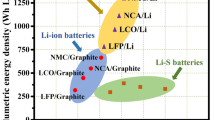

In the past decade, the extensive utilization of lithium-ion batteries (LIBs) has significantly advanced technology in areas such as electric vehicles, portable electronics, and grid-scale energy storage systems (ESSs) [1,2,3,4,5,6]. However, the limitations of the Li+ insertion/extraction chemistry have led LIBs to approach their energy density limits of 250 Wh kg−1 [7,8,9,10,11,12,13]. This restriction hinders their ability to meet the growing demand for high power and extended range in emerging applications. As a result, there is an increasing interest in exploring alternative energy storage systems that can surpass the performance of conventional LIBs.

Lithium-sulfur (Li–S) batteries have been gaining prominence as one of the most promising alternatives to conventional LIBs, primarily due to their high theoretical energy density of 2510 Wh kg−1 (or 2800 Wh L−1) [14, 15]. They utilize elemental sulfur as the cathode, which is abundant, cost-effective, and environmentally friendly [16,17,18,19,20,21,22,23]. Despite these favorable characteristics, realizing the full potential of Li–S batteries remains a complex and ongoing challenge [24,25,26,27,28,29,30].

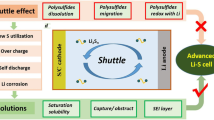

The maximum potential of Li–S batteries can be achieved by fully utilizing the active material, which entails the conversion of elemental sulfur (S8) to lithium sulfide (Li2S) and vice versa. Nevertheless, several factors impede the full utilization of sulfur, including the insulating properties of S8 and Li2S, the complex conversion reactions involving various dissoluble lithium polysulfide (LiPS) intermediates, and the shuttle effect that occurs between the cathode and anode [31,32,33,34,35,36,37,38]. Additionally, sulfur utilization is heavily dependent on the electrolyte quantity, as the reaction between sulfur and lithium is a distinctive solid–liquid-solid conversion process [27, 39].

Numerous studies have evaluated the performance of sulfur electrodes under high electrolyte-to-sulfur (E/S) ratio conditions, typically exceeding 10 μL mgsulfur−1, to achieve high specific capacities [40]. However, using a large amount of electrolytes comes at the expense of energy density. Even with a low E/S ratio of 3 μL mgsulfur−1, the electrolyte mass accounts for approximately 47.5% of the cell’s total weight, far above the typical values of conventional LIBs [41]. Although minimizing the E/S ratio can enhance energy density, it can also give rise to problems such as low ionic conductivity, sluggish reaction kinetics, and ultimately, poor cycle life. Therefore, it is crucial to explore electrolytes that can function effectively in lean conditions while simultaneously addressing these problems.

Among the electrolytes, 1,3-dioxolane/1,2-dimethoxyethane (DOL/DME) has been widely used due to its superior ability to form a stable interface with lithium metal anodes (LMAs). However, DOL/DME encounters challenges when employed with a low E/S ratio in Li–S battery cells. Reduced E/S ratio impedes the dissolution of long-chain polysulfides, consequently diminishing reaction kinetics. To deal with this issue, the concept of highly solvating electrolytes (HSEs) has been introduced. These electrolytes, such as N,N-dimethylacetamide (DMA) and dimethyl sulfoxide (DMSO), with a high Gutmann donor number (DN), have enhanced solubility to long-chain polysulfides [27, 42,43,44,45]. As a result, improved reaction kinetics and sulfur utilization can be achieved even under low E/S ratio [24, 26, 27]. However, these advantages come with a trade-off, as the intensified shuttle effect leads to compatibility issues with LMAs, ultimately affecting the battery’s cycle life.

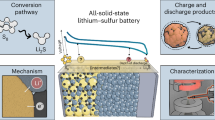

The objective of this review is to provide a comprehensive overview of the current state of research on HSEs in Li–S batteries. Our investigation will address the radical-containing reaction mechanism and the form of Li2S deposition due to the high solvation power of HSEs. It will also include the challenges faced by HSEs and introduce potential strategies to overcome these obstacles. Our goal is to provide scientific insights that will contribute to the development of high-performance Li–S batteries and pave the way for further advances in the field of energy storage.

Highly Solvating Electrolytes

As previously mentioned, HSEs are being treated as prospective solutions to increase the energy density of Li–S batteries. Enhanced LiPS solubility in HSEs is attributed to the formation of trisulfur radical anions (S3•−) which creates a new reaction pathway that facilitates the conversion reaction, leading to significantly improved sulfur utilization and reduced E/S ratio. Additionally, the use of HSEs can effectively mitigate the passivation of the electrode by Li2S, an insulating material. Generally, solid-state Li2S is formed at the end of the conversion and passivates the electrode surface of the active materials. However, HSEs have high solvating power to increase the nucleation overpotential of Li2S inducing slow 3D deposition to expose fresh surfaces. This enables HSEs to both prevent passivation and maintain battery performance over multiple cycles.

Enhancing LiPS Solubility for Improved Performance in Li–S Batteries

LiPS is a crucial component in the electrochemical operation of Li–S batteries. During discharge, sulfur in the cathode reacts with lithium ions, forming soluble LiPSs with various chain lengths that can readily transfer between the cathode and anode through the electrolyte. The soluble nature of LiPSs leads to their accumulation at the cathode-electrolyte interface, thereby facilitating their conversion and improving reaction kinetics. However, their low solubility in most electrolytes limits the utilization of active materials in the cathode, demanding an excess amount of electrolyte in a cell. To address this, researchers have investigated the use of HSEs with strong Lewis basicity to coordinate with Li+ and further increase the solubility of LiPSs. This approach improves sulfur utilization and thus the volumetric energy density.

Comparing the performance of HSEs with conventional electrolyte, Pan et al. [44] conducted LiPS solubility tests for different types of electrolytes. Their results showed that DMSO with a high dielectric constant (ε) of 46.5 had a saturation solubility of 6 M for Li2S6, which was 6 times higher than that of DOL/DME (Fig. 1a). According to Gupta et al. [45], such low LiPS solubility of DOL/DME is not suitable for achieving low E/S ratio under practical conditions. They correlated LiPS solubility with the E/S ratio based on a cell level with 75 wt% sulfur content in the cathode (Fig. 1b, c). Theoretically, the E/S ratio of 5 μL mgsulfur−1 corresponds to 1 M Li2S6, while practically, the E/S ratio of 2 μL mgsulfur−1 corresponds to 1.6 M Li2S6. As shown in Fig. 1d, all polysulfides were clearly soluble in high DN solvents (DMA, DMSO, and 1-Methylimidazole (MeIm)), whereas DOL/DME, which has a relatively low DN, displayed an obvious precipitation, reflecting its incapability to accommodate high polysulfide concentrations. Zhang et al. [46] reported a cosolvent of high-ε tetramethylurea (TMU) and DOL in a 1:1 volume ratio, which can dissolve Li2S4 and Li2S8 up to 1.3 M and 1 M, respectively (Fig. 1e). DOL/TMU demonstrated the highest reversible capacity (approximately 500 mAh g−1) with a stable average Coulombic efficiency of 99.6% during 180 cycles at the cell level (Fig. 1f). Furthermore, the pouch cell exhibited high sulfur utilization of 91.0% and high energy density of 324 Wh kg−1 (Fig. 1g). Cheng et al. [47] developed a new eutectic solvent composed of ε-caprolactam (CPL) and acetamide in a 1:1 molar ratio to dissolve a maximum of 0.7 M Li2Sx (where x = 1, 2, 4, 6, 8), respectively (Fig. 1h). The solvent exhibited considerable solubility of LiPSs even after being mixed with a 1:1 volume ratio of DOL/DME (Fig. 1i). Baek et al. [26] identified a novel high DN solvent, known as 1,3-dimethyl-2-imidazolidinone (DMI), that has the ability to solvate 1.5 M Li2S6. In contrast, DOL/DME and ethylene carbonate/dimethyl carbonate (EC/DMC) demonstrated limited solvation capacity, resulting in the precipitation of Li2S6 instead of dissolution (Fig. 1j).

Copyright 2015, Wiley–VCH. E/S ratio and Li2S6 concentration in relation to b theoretical specific energy (assumed a capacity as 1672 mAh g−1) c practical specific energy (assumed a capacity as 1000 mAh g−1). d Optical images of 1.5 M Li2S6 solubility tests for DOL/DME, DMA, DMSO, and MeIm along with DN and dielectric constant. Reproduced with permission [45]. Copyright 2019, Wiley–VCH. e Solubility of Li2S8 and Li2S4 in DOL/TMU and DOL/DME. f Cycling performance of Li|polysulfide cells using carbon paper as cathode current collectors at a current density of 0.1 C. g The galvanostatic curve of the initial cycle of a pouch cell with TMU electrolyte (S loading: 2.5 mg cm−2). Reproduced with permission [46]. Copyright 2018, Wiley–VCH. Optical images of solubility test for h the eutectic solvents and i the eutectic solvents/DOL/DME (2:1:1 vol%) with saturated Li2Sx (where x = 1, 2, 4, 6, 8). Reproduced with permission [47]. Copyright 2019, Wiley–VCH. j Optical images of (top) 1.5 M Li2S6 in DMI, DOL/DME, DMA, DMSO, and EC/DMC, and (bottom) 0.1 M Li2S in the same solvents. Reproduced with permission [26]. Copyright 2020, Wiley–VCH

a LiPS solubility test for DMSO, THF (Tetrahydrofuran), DOL/DME. Reproduced with permission [44].

Influence of Electrolyte Properties on the Conversion Reaction Mechanisms of Sulfur

HSEs exhibit a unique disproportionation and dissociation behavior associated with blue radical species (S3•−) [48], which have been detected through Ultraviolet–visible (UV–vis) spectroscopy [48,49,50] and electron spin resonance measurements [48, 50]. Depending on the presence of these species, they significantly influence the electrochemical characteristics of HSEs compared to DOL/DME.

-

(i)

DOL/DME

Lu et al. [51] conducted rotating ring disk electrode (RRDE) studies, which confirmed that S82− is generated initially through the two-electron reduction of S8 (Eq. 1), as previously proposed in the literature [42, 49,50,51,52,53,54,55,56].

$${{\text{S}}}_{8}+2{{\text{e}}}^{-}\to {{\text{S}}}_{8}^{2-}$$(1)$${{\text{S}}}_{8}^{2-}+2{{\text{e}}}^{-}\to {2{\text{S}}}_{4}^{2-}$$(2)The generation of solid-state species during the sulfur reduction in DOL/DME was suggested by previous studies such as RRDE [51] and operando X-ray absorption spectroscopy (XAS) [57].

$${{\text{S}}}_{4}^{2-}+2{{\text{e}}}^{-}\to {2{\text{S}}}_{2}^{2-}$$(3) -

(ii)

HSEs

Unlike in DOL/DME, the reduction of S82− produces both S62− and S8, as reflected in the UV spectra by an increase of the S62− signal (Eq. 4) [16, 43, 56, 58,59,60,61].

$${{\text{S}}}_{8}^{2-}\to {{\text{S}}}_{6}^{2-}+\frac{1}{4}{{\text{S}}}_{8}$$(4)The subsequent increase of the S3•− signal is characterized by the dissociation of S62− (Eq. 5) [16, 43, 56, 58,59,60,61].

$${{\text{S}}}_{6}^{2-}\to 2{{\text{S}}}_{3}^{\cdot -}$$(5)Through the second plateau in the discharging process, S3•− undergoes further reduction, leading to S32− and S42− (Eqs. 6, 7) [42, 43, 62, 63]. S42− and S3•− react with S8 to facilitate the abundant utilization of sulfur sources [16, 42, 43, 58,59,60,61,62,63].

$${{\text{S}}}_{3}^{\cdot -}+ {{\text{e}}}^{-}\to {{\text{S}}}_{3}^{2-}$$(6)$${{\text{S}}}_{3}^{2-}+ 2{{\text{S}}}_{3}^{\cdot -}\to {3{\text{S}}}_{4}^{2-}$$(7)$${{\text{S}}}_{4}^{2-}+\frac{1}{4}{{\text{S}}}_{8}\to 2{{\text{S}}}_{3}^{\cdot -}$$(8)$${2{\text{S}}}_{3}^{\cdot -}+ \frac{1}{4}{{\text{S}}}_{8}\to {{\text{S}}}_{8}^{2-}$$(9)Finally, when it comes to the depletion of S82− and S3•−, Li2S is formed as a final product.

$${{\text{S}}}_{4}^{2-}+6{{\text{e}}}^{-}\to {4{\text{S}}}^{2-}$$(10)

Cuisinier et al. [42] implemented X-ray absorption near edge structure (XANES) to investigate the conversion mechanisms of sulfur in HSEs, specifically DMA. The study revealed that sulfur was fully consumed by S3•− during discharge, as indicated by the simultaneous disappearance of elemental sulfur and S3•− (Fig. 2a). Using linear combination fitting (LCF) analysis of XANES spectra (Fig. 2b), they were able to distinguish the S3•− peak (2468.5 eV) from that of Sn2− (2470.5 eV, n = 4, 6, 8) and elucidate the significant fraction of S42− in the second step of discharge (Eq. 7). These results were consistent with the galvanostatic curve of the initial cycle, which showed 94% utilization of sulfur (Fig. 2c). Zou and Lu [63] conducted an operando UV–vis spectroscopy analysis in both DOL/DME and DMSO to verify the stability of intermediate sulfur species (Fig. 2d–g). They found that stable intermediates in DOL/DME were limited to only S42− species, while DMSO facilitated multiple reaction pathways through S3•−. They were able to demonstrate the disproportionation of S82− and dissociation of S62− (Eqs. 4, 5). Additional UV–vis spectra of N,N-dimethylformamide (DMF) showed lower Sn2− peaks but a higher S3•− peak (at 617 nm) than DMSO, which suggests that S3•− is more stable in DMF, resulting in reduced electrochemical polarization (Fig. 2h, i). The effectiveness of DMI, a new high DN solvent, in stabilizing S3•− has been substantiated by optical images of 0.1 M Li2S in the solvent and UV–vis absorption spectra of 1 mM Li2S6 in the solvent [26].

Copyright 2015, Wiley–VCH. d Cyclic voltammetry (CV) of 2.0 mM S8 and 1.0 M Lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) in DMSO (top left) and operando UV − vis spectra for each reaction step throughout the CV scan. e UV − vis absorbance at 617 and 492 nm during the CV. f CV of 2.0 mM S8 and 1.0 M LiTFSI in DOL/DME (top) and operando UV − vis spectra for each reaction step throughout the CV scan. g UV − vis absorbance at 420 nm during the CV. h UV − vis absorption spectra of 2.0 mM S62− in DMSO and DMF. i Galvanostatic curves of 4.0 mM S8 and 1.0 M LiTFSI in DMSO and DMF at 1 C. Reproduced with permission [63]. Copyright 2015, American Chemical Society. j UV − vis absorption spectra of 1.0 mM of Li2S6 in DMI, DMA, DMSO, DOL/DME. Reproduced with permission [26]. Copyright 2020, Wiley–VCH

a Sulfur K-edge XANES during discharge (around 340 mAh g−1) in Li–S cells using DMA and DOL/DME electrolytes compared with S3•− and S62− reference materials. b LCF analysis of the XANES spectra. c The galvanostatic curves of sulfur in tetraethylene glycol dimethyl ether (TEGDME) and DMA electrolytes at 0.1 C. (Solid: first cycle, dotted: second cycle) Reproduced with permission [42].

Impact of Solvent Dynamics on the Morphology of Li2S Deposition

The reaction between sulfur and lithium generates soluble polysulfides with various chain lengths, eventually leading to the insoluble Li2S. However, the low ionic conductivity of Li2S affects the growth pattern and reversibility of charge and discharge processes. Due to the conductivity limitations, Fan et al. [64] discovered that Li2S growth in the thickness direction through bulk diffusion is not favored. By means of a potentiostatic experiment, they proposed that the lateral growth of Li2S is attributed to the reduction of polysulfides in solution at the three-phase boundary between Li2S precipitates, a substrate, and the solution (Fig. 3a, b). Furthermore, they conducted a comparative study of discharge currents at C/4 and C/24 to explore the relationship between discharge rate and Li2S morphology (Fig. 3c, d). The study indicated that particle growth dominates at slow discharge rates, while nucleation dominates at higher rates.

Copyright 2015, Wiley–VCH. SEM images of Li2S morphologies discharged e in TMS f in DMSO. Reproduced with permission [65]. Copyright 2017, Springer Nature. g Schematic illustration of 2DP/2DI (Bewick, Fleischman, and Thirsk (BFT) models) and 3DP/3DI (Scharifker–Hills (SH) models). h Chronoamperograms of Li2S deposition in various electrolytes. (im: peak current; tm: time needed to achieve the peak current) Reproduced with permission [66]. Copyright 2019, Wiley–VCH

a Schematic image of the mechanism for the lateral growth of Li2S. b Potentiostatic experiment. SEM images of polysulfide solution-multi-walled carbon nanotube (MWCNT) cathodes discharged c at C/4 and d C/24. Scale bars are 200 nm. Reproduced with permission [64].

To confirm the impact of DN on the Li2S deposition pattern, Pan et al. [65] presented scanning electron microscope (SEM) images of the morphologies of Li2S after discharging in solvents with different DN (Fig. 3e, f). They observed that the low DN solvent, tetramethylene sulfone (TMS) resulted in a 2D film-shaped morphology, whereas the high DN solvent, DMSO produced a 3D particle-shaped morphology. Similarly, Li et al. [66] investigated the kinetics of Li2S deposition in solvents with varying DN by analyzing current–time transient curves from chronoamperic tests using four classical models of the electrochemical deposition (Fig. 3g). They elucidated that the behavior of low DN glymes could be explained by a 2D nucleation model, indicating that diffusion predominantly occurs along the surface. On the other hand, high DN solvents facilitated more solvated Li2S diffusion in the solution before it precipitated onto the Li2S clusters, following a 3D nucleation model (Fig. 3h). Choi’s group [24, 26, 27] noted a significant difference in Li2S morphologies in two distinct types of electrolytes: DOL/DME and HSEs. In DOL/DME, the insulating Li2S grew laterally, resulting in surface passivation. Conversely, HSEs exhibited high nucleation overpotential followed by low nucleation density, thereby exposing a substantial surface area of the electrode with 3D particle-shaped Li2S deposition.

In short, the solvents with high DN effectively stabilize long-chain polysulfides, leading to a deceleration of the nucleation process [66]. Subsequently, a reduced density of nuclei results in 3D morphology of Li2S on the cathode surface and a great portion of the electrode surface remains exposed for fresh reaction [24, 26, 27, 65,66,67,68,69]. On the contrary, low DN solvents tend to show a rapid nucleation process, resulting in the formation of film-like insulating layer to passivate the cathode surface. Furthermore, in addition to these advantages, high DN solvents that possess Li2S solubility promote the reversible reaction of sulfur.

Conclusion and Future Outlook

Li − S batteries have emerged as a promising candidate for post-lithium-ion batteries owing to the high gravimetric capacity of elemental sulfur (1675 mAh g−1). To achieve the highest energy density by fully utilizing the capacity of sulfur, it is necessary to operate under lean electrolyte conditions. HSEs can facilitate this by enhancing the solubility of LiPSs mediated by the S3•−, leading to higher specific capacity and energy density even under low E/S ratio (Table 1). Also, HSEs provide a 3D deposition morphology of Li2S, ensuring a sufficient electrode surface to maintain the redox reaction without passivation.

While the application of HSEs represents an effective strategy to enhance kinetics and achieve high energy density in Li–S batteries, they also pose challenges such as the shuttle effect, which can lead to a detrimental reaction with the Li anode. Furthermore, the decrease in the E/S ratio increases the LiPS concentration, resulting in sacrificed ionic conductivity and expanded voltage hysteresis. This reduces sulfur utilization and energy efficiency, hindering the practical application of lean-electrolyte Li–S batteries.

To overcome these challenges, several strategies have been explored, including electrolyte engineering, artificial solid electrolyte interphase (SEI) layers formation, membrane modification, and the addition of excess Li-salts. In recent years, several studies have demonstrated remarkable approaches to stabilize Li-metal electrodes while maintaining LiPS solubility. As an example, in one study, 3-fluoropyridine (3-FPN), a dual functional high DN solvent with significant polysulfide solubility, was utilized to form LiF-rich SEI, resulting in enhanced cycling properties [24]. Additionally, other investigations modified the Li+ solvation structure to induce the 3D deposition of Li2S [67] and generate Li3N-rich SEI layers [68, 69] by using high DN salt anions (LiBr, LiNO3, LiSCN) in ether-based solvents. Both of these strategies formulate the stable SEI layers on lithium metal interfaces, leading to improved Li reversibility.

Further development of Li–S batteries utilizing HSEs requires a comprehensive approach. Optimization of electrolyte design is necessary to achieve an appropriate balance between polysulfide solubility and compatibility with LMAs. Additionally, it is essential to rationally design a sulfur cathode that effectively suppresses the formation and diffusion of LiPSs at the cathode. Moreover, an in-depth understanding of the electrochemical reaction mechanism of HSEs using advanced analytical methods is imperative.

References

H. Park, D.H. Yeom, J. Kim, J.K. Lee, Korean J. Chem. Eng. 32, 178 (2015)

H.S. Kang, P. Santhoshkumar, J.W. Park, G.S. Sim, M. Nanthagopal, C.W. Lee, Korean J. Chem. Eng. 37, 1331 (2020)

N. Venugopal, W.S. Kim, T. Yu, Korean J. Chem. Eng. 33, 1500 (2016)

M. Zhao, B.Q. Li, X.Q. Zhang, J.Q. Huang, Q. Zhang, ACS Cent. Sci. 6, 1095 (2020)

Y.R. Liang, C.Z. Zhao, H. Yuan, Y. Chen, W.C. Zhang, J.Q. Huang, D.S. Yu, Y.L. Liu, M.M. Titirici, Y.L. Chueh, H.J. Yu, Q. Zhang, InfoMat 1, 6 (2019)

X.W. Yu, A. Manthiram, Adv. Energy Sustain. Res. 2, 2000102 (2021)

P.G. Bruce, S.A. Freunberger, L.J. Hardwick, J.-M. Tarascon, Nat. Mater. 11, 19 (2012)

J.M. Tarascon, M. Armand, Nature 414, 359 (2001)

H.S. Ko, H.W. Park, G.J. Kim, J.D. Lee, Korean J. Chem. Eng. 36, 620 (2019)

Y. Li, Z.H. Li, C. Zhou, X.B. Liao, X.W. Liu, X.F. Hong, X. Xu, Y. Zhao, L.Q. Mai, Chem. Eng. J. 422, 130107 (2021)

R. Saroha, J.H. Ahn, J.S. Cho, Korean J. Chem. Eng. 38, 461 (2021)

V. Etacheri, R. Marom, R. Elazari, G. Salitra, D. Aurbach, Energy Environ. Sci. 4, 3243 (2011)

H. Li, Joule 3, 911 (2019)

J.W. Choi, D. Aurbach, Nat. Rev. Mater. 1, 1 (2016)

L. Shi, F.L. Zeng, X. Cheng, K.H. Lam, W.K. Wang, A.B. Wang, Z.Q. Jin, F. Wu, Y.S. Yang, Chem. Eng. J. 334, 305 (2018)

Y.X. Yin, S. Xin, Y.G. Guo, L.J. Wan, Angew. Chem. Int. Ed. 52, 13186 (2013)

A. Manthiram, S.H. Chung, C. Zu, Adv. Mater. 27, 1980 (2015)

R.J. Angelici, Acc. Chem. Res. 21, 387 (1988)

Q. Pang, X. Liang, C.Y. Kwok, L.F. Nazar, Nat. Energy 1, 1 (2016)

A. Manthiram, Y. Fu, S.H. Chung, C. Zu, Y.S. Su, Chem. Rev. 114, 11751 (2014)

M. Rana, B. Luo, M.R. Kaiser, I. Gentle, R. Knibbe, J. Energy Chem. 42, 195 (2020)

J. Xiang, Y. Zhao, L. Wang, C. Zha, J. Mater. Chem. A 10, 10326 (2022)

S. Kim, W.G. Lim, A. Cho, J. Jeong, C. Jo, D. Kang, S.M. Han, J.W. Han, J. Lee, ACS Appl. Energy Mater. 3, 2643 (2020)

A. Elabd, J. Kim, D. Sethio, S. Kang, T. Kang, J.W. Choi, A. Coskun, ACS Energy Lett. 7, 2459 (2022)

J. Kim, H. Shin, D.J. Yoo, S. Kang, S.Y. Chung, K. Char, J.W. Choi, Adv. Funct. Mater. 31, 2106679 (2021)

M. Baek, H. Shin, K. Char, J.W. Choi, Adv. Mater. 32, e2005022 (2020)

H. Shin, M. Baek, A. Gupta, K. Char, A. Manthiram, J.W. Choi, Adv. Energy Mater. 10, 2001456 (2020)

J. Kim, A. Elabd, S.Y. Chung, A. Coskun, J.W. Choi, Chem. Mater. 32, 4185 (2020)

H. Shin, D. Kim, H.J. Kim, J. Kim, K. Char, C.T. Yavuz, J.W. Choi, Chem. Mater. 31, 7910 (2019)

S.H. Je, T.H. Hwang, S.N. Talapaneni, O. Buyukcakir, H.J. Kim, J.S. Yu, S.G. Woo, M.C. Jang, B.K. Son, A. Coskun, J.W. Choi, ACS Energy Lett. 1, 566 (2016)

Z.Y. Zhao, G.R. Li, Z. Wang, M. Feng, M.Z. Sun, X.X. Xue, R.P. Liu, H.S. Jia, Z.Z. Wang, W. Zhang, H.B. Li, Z.W. Chen, J. Power. Sources 434, 226729 (2019)

F. Zhou, Z.S. Qiao, Y.G. Zhang, W.J. Xu, H.F. Zheng, Q.S. Xie, Q. Luo, L.S. Wang, B.H. Qu, D.L. Peng, Electrochim. Acta 349, 136378 (2020)

E.V. Kuzmina, E.V. Karaseva, D.V. Kolosnitsyn, L.V. Sheina, N.V. Shakirova, V.S. Kolosnitsyn, J. Power. Sources 400, 511 (2018)

A. Raulo, S. Bandyopadhyay, S. Ahamad, A. Gupta, R. Srivastava, P. Formanek, B. Nandan, J. Power. Sources 431, 250 (2019)

W. Li, J. Hicks-Garner, J. Wang, J. Liu, A.F. Gross, E. Sherman, J. Graetz, J.J. Vajo, P. Liu, Chem. Mater. 26, 3403 (2014)

K. Kim, P.J. Kim, J.P. Youngblood, V.G. Pol, Chemsuschem 11, 2375 (2018)

A.A. Razzaq, Y.Z. Yao, R. Shah, P.W. Qi, L.X. Miao, M.Z. Chen, X.H. Zhao, Y. Peng, Z. Deng, Energy Storage Mater. 16, 194 (2019)

S.J. Dai, Y. Feng, P. Wang, H. Wang, H.G. Liang, R.F. Wang, V. Linkov, S. Ji, Electrochim. Acta 321, 134678 (2019)

H. Ye, Y. Li, Nano Res. Energy 1, e9120012 (2022)

C.M. Li, H. Zhang, L. Otaegui, G. Singh, M. Armand, L.M. Rodriguez-Martinez, J. Power. Sources 326, 1 (2016)

C. Yang, P. Li, J. Yu, L.D. Zhao, L. Kong, Energy 201, 117718 (2020)

M. Cuisinier, C. Hart, M. Balasubramanian, A. Garsuch, L.F. Nazar, Adv. Energy Mater. 5, 1401801 (2015)

B.S. Kim, S.M. Park, J. Electrochem. Soc. 140, 115 (1993)

H.L. Pan, X.L. Wei, W.A. Henderson, Y.Y. Shao, J.Z. Chen, P. Bhattacharya, J. Xiao, J. Liu, Adv. Energy Mater. 5, 1500113 (2015)

A. Gupta, A. Bhargav, A. Manthiram, Adv. Energy Mater. 9, 1803096 (2019)

G. Zhang, H.J. Peng, C.Z. Zhao, X. Chen, L.D. Zhao, P. Li, J.Q. Huang, Q. Zhang, Angew. Chem. Int. Ed. 57, 16732 (2018)

Q. Cheng, W. Xu, S. Qin, S. Das, T. Jin, A. Li, A.C. Li, B. Qie, P. Yao, H. Zhai, C. Shi, X. Yong, Y. Yang, Angew. Chem. Int. Ed. 58, 5557 (2019)

T. Chivers, I. Drummond, Inorg. Chem. 11, 2525 (1972)

R.P. Martin, W.H. Doub, J.L. Roberts, D.T. Sawyer, Inorg. Chem. 12, 1921 (1973)

Tobishima, S. I., Yamamoto, H. and Matsuda, M., Electrochim. Acta, (1997).

Y.C. Lu, Q. He, H.A. Gasteiger, J. Phys. Chem. C 118, 5733 (2014)

T. Fujinaga, T. Kuwamoto, S. Okazaki, M. Hojo, Bull. Chem. Soc. Japan 53, 2851 (1980)

P. Leghié, J.-P. Lelieur, E. Levillain, Electrochem. Commun. 4, 406 (2002)

J. Badoz-Lambling, R. Bonnaterre, G. Cauquis, M. Delamar, G. Demange, Electrochim. Acta 21, 119 (1976)

R. Bonnaterre, G.J. Cauquis, Chem. Soc. Chem. Commun. 5, 293 (1972)

A.S. Baranski, W.R. Fawcett, C.M. Gilbert, Anal. Chem. 57, 166 (1985)

Y. Gorlin, A. Siebel, M. Piana, T. Huthwelker, H. Jha, G. Monsch, F. Kraus, H.A. Gasteiger, M. Tromp, J. Electrochem. Soc. 162, A1146 (2015)

R. Chen, T. Zhao, J. Lu, F. Wu, L. Li, J. Chen, G. Tan, Y. Ye, K. Amine, Nano Lett. 13, 4642 (2013)

P.G. Bruce, S.A. Freunberger, L.J. Hardwick, J.M. Tarascon, Nat. Mater. 11, 19 (2011)

L. Suo, Y.S. Hu, H. Li, M. Armand, L. Chen, Nat. Commun. 4, 1481 (2013)

F. Wu, J.Z. Chen, R.J. Chen, S.X. Wu, L. Li, S. Chen, T. Zhao, J. Phys. Chem. C 115, 6057 (2011)

J. Paris, V. Plichon, Electrochim. Acta 26, 1823 (1981)

Q. Zou, Y.C. Lu, J. Phys. Chem. Lett. 7, 1518 (2016)

F.Y. Fan, W.C. Carter, Y.M. Chiang, Adv. Mater. 27, 5203 (2015)

H.L. Pan, J.Z. Chen, R.G. Cao, V. Murugesan, N.N. Rajput, K.S. Han, K. Persson, L. Estevez, M.H. Engelhard, J.G. Zhang, K.T. Mueller, Y. Cui, Y.Y. Shao, J. Liu, Nat. Energy 2, 813 (2017)

Z. Li, Y. Zhou, Y. Wang, Y.-C. Lu, Adv. Energy Mater. 9, 1802207 (2019)

H. Chu, H. Noh, Y.-J. Kim, S. Yuk, J.-H. Lee, J. Lee, H. Kwack, Y. Kim, D.-K. Yang, H.-T. Kim, Nat. Commun. 10, 188 (2019)

H. Chu, J. Jung, H. Noh, S. Yuk, J. Lee, J.-H. Lee, J. Baek, Y. Roh, H. Kwon, D.W. Choi, K. Sohn, Y.K. Kim, H.-T. Kim, Adv. Energy Mater. 10, 2000493 (2020)

J. Jung, H. Chu, I. Kim, D.H. Lee, G. Doo, H. Kwon, W. Jo, S. Kim, H. Cho, H.-T. Kim, Adv. Sci. 10, 2301006 (2023)

B. Celine, L. Jeam-Claude, P. Sébastien, A. Fannie, Electrochim. Acta 89, 737 (2013)

Acknowledgements

We acknowledge the support from the National Research Foundation of Korea (NRF) (NRF-2021M3H4A3A02086210), the Technology Innovation Program (20012341) funded by the Ministry of Trade, Industry & Energy (MOTIE) of Korea, and generous support from the Institute of Engineering Research (IOER) and Research Institute of Advanced Materials (RIAM) at Seoul National University.

Funding

Open Access funding enabled and organized by Seoul National University. This article is funded by National Research Foundation of Korea, NRF-2021M3H4A3A02086210, Jang Wook Choi, Ministry of Trade, Industry and Energy, 20012341, Jang Wook Choi.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kang, T., Kang, N. & Choi, J.W. Overview of Highly Solvating Electrolytes for Lean Electrolyte Conditions in Lithium–Sulfur Batteries. Korean J. Chem. Eng. 41, 375–383 (2024). https://doi.org/10.1007/s11814-024-00103-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00103-7