Abstract

The demand for gelatin is increasing in the market due to its use in functional foods, beverage products, and pharmaceuticals. However, most gelatin is made from pig/bovine which is not halal, making it unsuitable for consumption by some people. Therefore, an alternative raw material for gelatin production should be found to meet the restrictions of gelatin sources. Shrimp shells, a food waste from shrimp production, can be used as an alternative source for gelatin as it contains protein, chitin, and minerals. This research aimed to study the development of the gelatin production process from shrimp shells and evaluated the techno-economic analysis of two different biochemical processing scenarios. The results showed that the production yield was 40% and 45% for scenarios I and II, respectively. To address economic feasibility, various economic indicators were evaluated. The payback period was 4.20 and 0.90 years, and the return on investment was 27.03% and 124.33% for scenarios I and II, respectively. Additionally, the energy efficiency was 7.28 and 8.01 kg of product/kWh and the environmental impacts were 0.28 and 0.24 kg of CO2 equivalent for scenarios I and II, respectively. This developed gelatin process from shrimp shell biomass could be a promising technology for gelatin production at an industrial scale.

Similar content being viewed by others

References

Grand View Research, Gelatin market size, share & trends analysis report by source (Bovine, Porcine), By function (Stabilizer, Thickener), By application (Food & Beverages, Healthcare), By region, and segment forecasts, 2023–2030,” https://www.grandviewresearch.com/industry-analysis/gelatin-market-analysis.

O. Lu Ki, Z. Danujatmiko, and Y. Sudaryanto, The prospect of shrimp shell waste as raw material in the gelatin production 9(11), (2014), [Online]. Available: www.arpnjournals.com

M. Mosquera, B. Giménez, P. Montero, M.C. Gómez-Guillén, Incorporation of liposomes containing squid tunic ACE-1 inhibitory peptides to fish gelatin. J. Sci. Food Agric. 96(3), 769–776 (2016)

Y. Lu et al., Application of gelatin in food packaging: a review. Polymers 14, 58 (2022). https://doi.org/10.3390/polym14030436

T. Ahmad et al., Extraction, characterization and molecular structure of bovine skin gelatin extracted with plant enzymes bromelain and zingibain. J. Food Sci. Technol. 57(10), 3772–3781 (2020). https://doi.org/10.1007/s13197-020-04409-2

K. Su, C. Wang, Recent advances in the use of gelatin in biomedical research. Biotechnol. Lett. 37(11), 2139–2145 (2015). https://doi.org/10.1007/s10529-015-1907-0

F. Milano, A. Masi, M. Madaghiele, A. Sannino, L. Salvatore, N. Gallo, Current trends in gelatin-based drug delivery systems. Pharmaceutics (2023). https://doi.org/10.3390/pharmaceutics15051499

S. Al-Nimry, A.A. Dayah, I. Hasan, R. Daghmash, Cosmetic, biomedical and pharmaceutical applications of fish gelatin/hydrolysates. Marine Drugs (2021). https://doi.org/10.3390/MD19030145

A. Evans, Written and produced by the members of the GMIA GELATIN Manufacturers Institute of America Gelatin HandboOK. [Online]. Available: http://www.gelita.com, http://www.nitta-gelatin.com, http://www.pbleiner.com, http://www.rousselot.com, http://www.weishardt.com

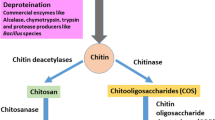

S. Ngasotter et al., Crustacean shell waste derived chitin and chitin nanomaterials for application in agriculture, food, and health–A review. Carbohydr. Polym. Technol. Appl. 6, 85 (2023). https://doi.org/10.1016/j.carpta.2023.100349

The state of world fisheries and aquaculture. FAO, (2022). https://doi.org/10.4060/cc0461en.

G.M. Mathew et al., Sustainable and eco-friendly strategies for shrimp shell valorization. Environ. Pollut. (2020). https://doi.org/10.1016/j.envpol.2020.115656

H.A. Al Hoqani, N.H. Al Shaqsi, M.A. Hossin, M.A. Al Sibani, Structural characterization of polymeric chitosan and mineral from Omani shrimp shells. Water-Energy Nexus 4, 199–207 (2021). https://doi.org/10.1016/j.wen.2021.11.002

M.M. Rahman, M. Maniruzzaman, A new route of production of the meso-porous chitosan with well-organized honeycomb surface microstructure from shrimp waste without destroying the original structure of native shells: extraction, modification and characterization study. Results Eng. (2023). https://doi.org/10.1016/j.rineng.2023.101362

X. Mao, N. Guo, J. Sun, C. Xue, Comprehensive utilization of shrimp waste based on biotechnological methods: a review. J. Clean. Prod. 143, 814–823 (2017). https://doi.org/10.1016/j.jclepro.2016.12.042

R. Rusmini, R.R. Manullang, D. Daryono, Development of shrimp shells-based compost and plant-based pesticide using bio-activators from golden apple snails and their effects on the kenaf plant growth and pest population. Nusantara Biosci. 9(3), 260–267 (2017). https://doi.org/10.13057/nusbiosci/n090304

N. Suryawanshi, J.S. Eswari, Shrimp shell waste as a potential raw material for biorefinery—A revisit. Biomass Conver. Biorefinery 12(5), 1977–1984 (2022). https://doi.org/10.1007/s13399-020-01271-2

M.J. Hülsey, Shell biorefinery: a comprehensive introduction. Green Energy Environ. 3(4), 318–327 (2018). https://doi.org/10.1016/j.gee.2018.07.007

J.J. Deng et al., One-step processing of shrimp shell waste with a chitinase fused to a carbohydrate-binding module. Green Chem. 22(20), 6862–6873 (2020). https://doi.org/10.1039/d0gc02611e

A. Zuorro, K.A. Moreno-Sader, Á.D. González-Delgado, Economic evaluation and techno-economic sensitivity analysis of a mass integrated shrimp biorefinery in North Colombia. Polym. (Basel) 12(10), 1–14 (2020). https://doi.org/10.3390/polym12102397

J.J. Deng et al., Enzymatic conversion and recovery of protein, chitin, and astaxanthin from shrimp shell waste. J. Clean. Prod. 271, 122655 (2020). https://doi.org/10.1016/j.jclepro.2020.122655

H.M. Ibrahim, M.F. Salama, H.A. El-Banna, Shrimp’s waste: chemical composition, nutritional value and utilization. Nahrung Food 43(6), 418–423 (1999). https://doi.org/10.1002/(sici)1521-3803(19991201)43:6%3c418::aid-food418%3e3.0.co;2-6

M.D. Shoulders, R.T. Raines, Collagen structure and stability. Annu. Rev. Biochem. 78, 929–958 (2009). https://doi.org/10.1146/annurev.biochem.77.032207.120833

D. Gómez-Ríos, G. Navarro, P. Monsalve, R. Barrera-Zapata, R. Ríos-Estepa, Aspen plus simulation strategies applied to the study of chitin ioextraction from shrimp waste. Food Technol Biotechnol 57(2), 238–248 (2019). https://doi.org/10.17113/ftb.57.02.19.6003

C. Achilli, A. Ciana, G. Minetti, Oxidation of cysteine-rich proteins during gel electrophoresis. J. Biol. Methods 5(4), e104–e104 (2018). https://doi.org/10.14440/jbm.2018.275

J.M. Becker, G.A. Caldwell, E.A. Zachgo, Exercise 13—Protein Assays, in Biotechnology, 2nd edn., ed. by J.M. Becker, G.A. Caldwell, E.A. Zachgo (Academic Press, San Diego, 1996), pp.119–124. https://doi.org/10.1016/B978-012084562-0/50069-2

D. Andrés Gómez Ríos and R. Ríos Estepa Chemical Engineering. Technical and economic feasibility analysis of a plant process for production of chitosan from shrimp shells in Colombia by (2015).

M.-O. Nicolas-Simonnot et al., Experimental study and modelling of gelatin production from bone powder: elaboration of an overall kinetic scheme for the acid process. Chem. Eng. J. 67(1), 55–64 (1997). https://doi.org/10.1016/S1385-8947(97)00010-7

P. Warinyupa, Shrimp farming in Thailand: A pathway to sustainability. Pomona College, Claremont, California, (2020).

S. Dechapinan, K. Judprasong, N. On-nom, N. Tangsuphoom, Calcium from Pacific white shrimp (Litopeneaus vannamei) shells: properties and function as fortificant in soy milk. Food Appl. Biosci. J. 5(3), 176–195 (2017). https://doi.org/10.14456/fabj.2017.15

P.S. Bundela, A. Kapoor, R.K. Jain, Co-processing of lime sludge of gelatin industry in cement Kiln. Electron. J. Environ. Agric. Food Chem. 9(9), 1502–1506 (2010)

T.S. Arturi, C.J. Seijas, G.L. Bianchi, A comparative study on the treatment of gelatin production plant wastewater using electrocoagulation and chemical coagulation. Heliyon 5(5), e01738 (2019). https://doi.org/10.1016/j.heliyon.2019.e01738

Acknowledgements

This research received financial support from the Faculty of Engineering, KMUTNB (NO.ENG-NEW-62-25). We would like also to thank the department of chemical engineering, KMUTNB for facilities support. Not forget to thank the Thai Union Group for their kind in-kind support.

Funding

This research received financial support from the Faculty of Engineering, KMUTNB (NO.ENG-NEW-62–25).

Author information

Authors and Affiliations

Contributions

PC: Investigation conducted experiments. WL: Investigation conducted experiments. RM: Investigation conducted experiments. PC: Conceptualization, Investigation, Writing -Review & Editing. PN: Review & Editing. SC: Conceptualization, Investigation, Writing—Original Draft, Writing—Review & Editing and Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

This manuscript does not contain any studies with human participants or animals performed by any authors.

Consent to Participate

Not applicable.

Consent to Publish

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Charoenkool, P., Leephakphumphanich, W., Muangnamsuk, R. et al. Process Analysis and Environmental Assessment of Gelatin Production From Shrimp Shell Wastes. Korean J. Chem. Eng. 41, 1105–1117 (2024). https://doi.org/10.1007/s11814-024-00042-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00042-3