Abstract

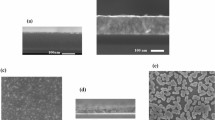

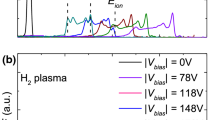

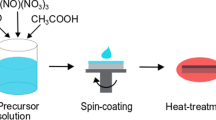

Ru is extensively used in electrical and energy applications because of its high electrical conductivity and catalytic activity. This study reports the H2 plasma-enhanced atomic layer deposition (PEALD) of Ru thin films using a novel carbonyl cyclohexadiene ruthenium precursor. The optimized process conditions for depositing Ru thin films by PEALD were established based on the growth per cycle (GPC), chemical formation, crystallinity, conformality, and resistivity, according to process parameters such as precursor pulse time, H2 plasma pulse time, purge time, and deposition temperature. Pure Ru thin films (low carbon and oxygen) were deposited with low resistivity (30.8 μΩ cm) and showed high conformality (> 95%) on the Si trenches. The oxidant-free PEALD Ru process reported in this study may have implications on the fabrication of high-quality interfaces between Ru and easily-oxidized substrates.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

N. Torazawa, T. Hinomura, S. Hirao, E. Kobori, H. Korogi, S. Matsumoto, ECS J. Solid State Sci. Technol. 5, P433 (2016)

J. Yu, Q. He, G. Yang, W. Zhou, Z. Shao, M. Ni, ACS Catal. 9, 9973–10011 (2019)

S. Kye, H.J. Kim, D. Go, B.C. Yang, J.W. Shin, S. Lee, J. An, ACS Catal. 11, 3523–3529 (2021)

S. Cwik, K.N. Woods, M.J. Saly, T.J. Knisley, C.H. Winter, J. Vac. Sci. Technol. A 38, 012402 (2020)

A. Rogozhin, A. Miakonkikh, E. Smirnova, A. Lomov, S. Simakin, K. Rudenko, Coatings 11, 117 (2021)

J.A. Kittl, K. Opsomer, M. Popovici, N. Menou, B. Kaczer, X.P. Wang, C. Adelmann, M.A. Pawlak, K. Tomida, A. Rothschild, Microelectron. Eng. 86, 1789–1795 (2009)

V. Misra, G. Lucovsky, G. Parsons, MRS Bull. 27, 212–216 (2002)

S.K. Kim, W.-D. Kim, K.-M. Kim, C.S. Hwang, J. Jeong, Appl. Phys. Lett. 85, 4112–4114 (2004)

J.H. Han, S.W. Lee, G.-J. Choi, S.Y. Lee, C.S. Hwang, C. Dussarrat, J. Gatineau, Chem. Mater. 21, 207–209 (2009)

H.J. Kim, M.J. Kil, J. Lee, B.C. Yang, D. Go, Y. Lim, Y. Kim, J. An, Appl. Surf. Sci. 538, 148105 (2020)

D. Go, B.C. Yang, J.W. Shin, H.J. Kim, S. Lee, S. Kye, S. Kim, J. An, Ceram. Int. 46(2), 1705–1710 (2020)

H.J. Jeong, J.W. Kim, K. Bae, H. Jung, J.H. Shim, ACS Catal. 5, 1914–1921 (2015)

H.J. Jeong, J.W. Kim, D.Y. Jang, J.H. Shim, J. Power. Sources 291, 239–245 (2015)

R.L. Puurunen, W. Vandervorst, J. Appl. Phys. 96, 7686–7695 (2004)

M. Schaefer, R. Schlaf, J. Appl. Phys. 118, 065306 (2015)

S.K. Kim, G. Choi, S.Y. Lee, M. Seo, S.W. Lee, J.H. Han, H. Ahn, S. Han, C.S. Hwang, Adv. Mater. 20, 1429–1435 (2008)

Z. Gao, D. Le, A. Khaniya, C.L. Dezelah, J. Woodruff, R.K. Kanjolia, W.E. Kaden, T.S. Rahman, P. Banerjee, Chem. Mater. 31, 1304–1317 (2019)

H.-J. Sun, K.-M. Kim, Y. Kim, K.-J. Cho, K.-S. Park, J.-M. Lee, J.-S. Roh, Jpn. J. Appl. Phys. 42, 582 (2003)

T.E. Hong, K.-Y. Mun, S.-K. Choi, J.-Y. Park, S.-H. Kim, T. Cheon, W.K. Kim, B.-Y. Lim, S. Kim, Thin Solid Films 520, 6100–6105 (2012)

J. Swerts, A. Delabie, M.M. Salimullah, M. Popovici, M.-S. Kim, M. Schaekers, S. Van Elshocht, Electrochem. Solid-State Lett. 1, P19 (2012)

Y. Kotsugi, S. Han, Y. Kim, T. Cheon, D.K. Nandi, R. Ramesh, N. Yu, K. Son, T. Tsugawa, S. Ohtake, R. Harada, Y. Park, B. Shong, S. Kim, Chem. Mater. 33(14), 5639–5651 (2021)

C.T. Nguyen, J. Yoon, R. Khan, B. Shong, Appl. Surf. Sci. 488, 896–902 (2019)

E.C. Ko, J.Y. Kim, H. Rhee, K.M. Kim, J.H. Han, Mater. Sci. Semicond. 156, 107258 (2023)

S.H. Oh, J.M. Hwang, H. Park, D. Park, Y.E. Song, E.C. Ko, T.J. Park, T. Eom, T.M. Chung, Adv. Mater. Interfaces 10, 2202445 (2023)

S.M. George, Chem. Rev. 110, 111–131 (2010)

M. Kariniemi, J. Niinistö, M. Vehkamäki, M. Kemell, M. Ritala, M. Leskelä, M. Putkonen, J. Vac. Sci. Technol. A 30, 01A115 (2012)

J. Dendooven, D. Deduytche, J. Musschoot, R.L. Vanmeirhaeghe, C. Detavernier, J. Electrochem. Soc. 157, G111 (2010)

S. Novak, B. Lee, X. Yang, V. Misra, J. Electrochem. Soc. 157, H589 (2010)

C. de Paula, N.E. Richey, L. Zeng, S.F. Bent, Chem. Mater. 32, 315–325 (2019)

W.-J. Lee, E.-Y. Yun, S.W. Hong, S.-H. Kwon, Appl. Surf. Sci. 519, 146215 (2020)

J.W. Shin, J. Lee, K. Kim, C. Kwon, Y. Bin Park, H. Park, K. Kim, H.S. Ahn, D. Shim, J. An, Ceram. Int. 48, 25651–25655 (2022)

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 20220R1A2C4001205), Basic Science Research Program through the National Research Foundation of Korea(NRF) funded by the Ministry of Education(NRF-2021R1A6A1A03039981), the Technology Innovation Program (No. 20010630) funded by the Ministry of Trade, Industry and Energy (MOTIE) of Korea, and Samsung Electronics Co., Ltd (IO230414-05954-01). The carbonyl cyclohexadiene ruthenium precursor was provided by Air Liquide.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, G., Kim, K., Shin, J.W. et al. Hydrogen Plasma-Assisted Atomic Layer Deposition of Ru with Low Oxygen Content. Korean J. Chem. Eng. 41, 1249–1254 (2024). https://doi.org/10.1007/s11814-024-00035-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00035-2