Abstract

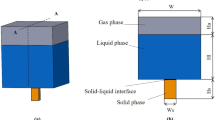

In order to improve the boiling heat transfer capacity within the microstructure, a superhydrophilic surface model with a bionic flower bud structure was established and the flow-boiling heat transfer characteristics were simulated. The temperature, velocity and vapor phase distribution contours under different working conditions were obtained. The effects of different flower spacings, superheat degrees and surfaces on boiling heat transfer were discussed. The study found that the droplet has more vaporization cores on the superhydrophilic surface, and the bubbles can effectively destroy the velocity and temperature boundary layers, thereby enhancing the boiling heat transfer ability. The heat transfer area under the narrow flower spacing is larger, and the vaporization core is more, which is more conducive to boiling heat transfer. When the superheat degree is 80 K, the superhydrophilic surface with the flower spacing L=0 µm has the strongest heat transfer ability, which is 1.59 times that of the common surface, and the mass transfer rate is increased by 23.5%.

Similar content being viewed by others

Abbreviations

- A:

-

interface area [m2]

- c:

-

specific heat capacity [J·kg−1-K−1]

- db :

-

bubble diameter [m]

- E:

-

internal energy [J]

- F:

-

surface tension source term [N·m−3]

- g:

-

acceleration of gravity [m·s−2]

- h:

-

heat transfer coefficient [W·m2·K−1]

- hf :

-

standard state enthalpy [J·kg−1·mol−1]

- hs :

-

enthalpy of saturated state [J·kg−1·mol−1]

- k:

-

thermal conductivity [W·m−1·K−1]

- L:

-

length [m]

- L qr :

-

latent heat [kJ·kg−1]

- mlv :

-

mass exchange rate [kg·m−3·s−1]

- M:

-

molar mass [kg·kmol−1]

- P:

-

pressure [Pa]

- Rb :

-

bud radius [m]

- R:

-

gas constant

- S:

-

source term

- T:

-

temperature [K]

- t:

-

time [s]

- u:

-

velocity [m·s−1]

- β :

-

accommodation coefficient

- η :

-

evaporative heat transfer coefficient

- μ :

-

dynamic viscosity [Pa·s]

- ρ :

-

density [kg·m−3]

- l:

-

liquid phase

- v:

-

gas phase

- *:

-

gas phase part

References

X. Yang, J. Liu, G. Wang and J. Wei, Appl. Therm. Eng., 210, 118350 (2022).

Y. Wang, C. Qi, R. Zhao and C. Wang, Appl. Therm. Eng., 208, 118258 (2022).

E. C. Okonkwo, I. Wole-Osho, I. W. Almanassra, Y. M. Abdullatif and T. Al-Ansari, J. Therm. Anal. Calorim., 145(6), 2817 (2021).

T. G. Karayiannis and M. M. Mahmoud, Appl. Therm. Eng., 115, 1372 (2017).

Y. Jia, J. Huang, J. Wang and H. Li, Entropy, 23(11), 1482 (2021).

Z. Xu, J. Wang, Y. Jia, X. Geng and Z. Liu, Appl. Therm. Eng., 108, 150 (2016).

Y. Jia, S. Yao, J. Wang and H. Li, Chem. Ind. Eng. Prog., 40(12), 6423 (2021).

K. Zhang, L. Bai, H. Jin, G. Lin, G. Yao and D. Wen, Appl. Therm. Eng., 202, 117759, (2022).

S. Rostami, M. Afrand, A. Shahsavar, M. Sheikholeslami, R. Kalbasi, S. Aghakhani, M. S. Shadloo and H. F. Oztop, Energy, 211, 118698 (2020).

S. Deb, M. Das, D. C. Das, S. Pal, A. K. Das and R. Das, Int. J. Heat Mass Transf., 170, 120994 (2021).

S. Deb, S. Pal, D. C. Das, M. Das, A. K. Das and R. Das, Heat Mass Transfer, 56(12), 3273 (2020).

T. Y. Zhang, L. W. Mou, Y. C. Zhang, J. Y. Zhang, J. Q. Li and L. W. Fan, Case Stud. Therm. Eng., 24, 100882 (2021).

T. Y. Zhang, L. W. Mou and L. W. Fan, Appl. Therm. Eng., 185, 116453 (2021).

A. Recinella and S. G. Kandlikar, J. Heat Trans-T Asme, 140(2), 021502 (2018).

K. P. Drummond, D. Back, M. D. Sinanis, D. B. Janes, D. Peroulis, J. A. Weibel and S. V. Garimella, Int. J. Heat Mass Transf., 117, 319 (2018).

P. Cheng, G. Wang and X. Quan, J. Heat Trans-T Asme, 131(4), 043211 (2009).

H. Sun, G. Lin, H. Jin, X. Bu, C. Cai, Q. Jia, K. Ma and D. Wen, Renew. Energ., 179, 1179 (2021).

T. P. Rasitha, C. Thinaharan, S. C. Vanithakumari and J. Philip, Colloid Surf. A, 636, 128110, (2022).

R. TP and J. Philip, Appl. Surf. Sci., 585, 152628 (2022).

S. C. Vanithakumari, G. Jena, S. Sofia, C. Thinaharan, R. P. George and J. Philip, Surf. Coat. Tech., 400, 126074 (2020).

W. Li, K. Zhou, J. Li, Z. Feng and H. Zhu, Int. J. Heat Mass Transf., 119, 601 (2018).

W. Zhou, D. Han and G. Xia, Appl. Surf. Sci., 591, 153155 (2022).

N. G. Tran and D. M. Chun, J. Mater. Process. Tech., 297, 117245 (2021).

A. S. T. Kaya and U. Cengiz, Prog. Org. Coat., 126, 75 (2019).

T. Adachi, S. S. Latthe, S. W. Gosavi, N. Roy, N. Suzuki, H. Ikari, K. Kato, K. i. Katsumata, K. Nakata, M. Furudate, T. Inoue, T. Kondo, M. Yuasa, A. Fujishima and C. Terashima, Appl. Surf. Sci., 458, 917 (2018).

Y. Ma, J. Tong, M. Zhuang, J. Liu, S. Cheng, X. Pei, H. Li and D. Sang, Results Phys., 15, 102628 (2019).

A. Mahringer, M. Hennemann, T. Clark, T. Bein and D. D. Medina, Angew. Chem. Int. Ed. Eng., 60(10), 5519 (2021).

O. Sato, S. Kubo and Z. Z. Gu, Accounts Chem. Res., 42(1), 1 (2009).

Y. Deng, G. Zhang, R. Bai, S. Shen, X. Zhou and I. Wyman, J. Membr. Sci., 569, 60 (2019).

Y. Feng, F. Chang, Z. Hu, H. Li and J. Zhao, Int. J. Therm. Sci., 163, 106814 (2021).

L. Liao, R. Bao and Z. Liu, Heat Mass Transfer, 44(12), 1447 (2008).

R. Liu and Z. Liu, Int. J. Heat Mass Transf., 143, 118534 (2019).

K. Vontas, M. Andredaki, A. Georgoulas, N. Miché and M. Marengo, Int. J. Heat Mass Transf., 172, 121133 (2021).

H. T. Phan, N. Caney, P. Marty, S. Colasson and J. Gavillet, CR. Mécanique, 337(5), 251 (2009).

G. D. Sia, M. K. Tan, G. M. Chen and Y. M. Hung, Case Stud. Therm. Eng., 27, 101283 (2021).

G. Yang, J. Liu, X. Cheng, Y. Wang, X. Chu, S. Mukherjee, A. Terzis, A. Schneemann, W. Li, J. Wu and R. A. Fischer, J. Mater. Chem. A, 9(45), 25480 (2021).

Y. S. Lim and Y. M. Hung, Energy Convers. Manage., 244, 114522 (2021).

H. Ze, F. Wu, S. Chen and X. Gao, Adv. Mater. Interfaces, 7(14), 2000482 (2020).

Y. Nam, E. Aktinol, V. K. Dhir and Y. S. Ju, Int. J. Heat Mass Transf., 54(7–8), 1572 (2011).

C. W. Lin, Y. C. Lin, T. C. Hung, M. C. Lin and H. Y. Hsu, Int. J. Heat Mass Transf., 171, 121058 (2021).

H. Zhan, S. Li, Z. Jin, G. Zhang, L. Wang, Q. Li and Z. Zhang, J. Mech. Sci. Technol., 36(2), 1025 (2022).

K. Ling, Z. Y. Li and W. Q. Tao, Numer. Heat Tr. A-Appl., 65(10), 949 (2014).

K. Vontas, M. Andredaki, A. Georgoulas, N. Miché and M. Marengo, Int. J. Heat Mass Transf., 172, 121133 (2021).

M. Knudesen, The kinetic theory of gases, CRC Press. Publications, Boston (1998).

D. Lide, CRC handbook of chemistry and physics, CRC Press. Publications, Florida (2003).

J. Zhang, Study on enhanced boiling heat transfer characteristics of microstructured heat exchange surfaces, MA thesis, JUST, Zhenjiang (2016).

Y. Lin, Y. Luo, W. Li and W. J. Minkowycz, Int. J. Heat Mass Transf., 179, 121739 (2021).

Acknowledgements

This work is financially supported by Natural Science Foundation of Jiangsu Province, China (Grant No. BK20181359).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, Z., Wang, C., Qi, C. et al. Boiling heat transfer characteristics of bionic flower bud structure microchannels. Korean J. Chem. Eng. 39, 3246–3260 (2022). https://doi.org/10.1007/s11814-022-1256-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-022-1256-3