Abstract

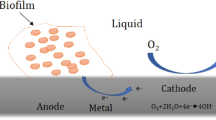

The performance of sodium molybdate (Na2MoO4) (VI) as a corrosion inhibitor for medium carbon steel corrosion in saline water containing nitrate and chloride ions was studied at various inhibitor concentrations, temperatures, exposure times and rotational velocities. Mass loss and electrochemical techniques were used to evaluate the corrosion rates. The individual and interactive effects of these four parameters were optimized for minimum response of corrosion rate using central composite design (CCD) with response surface methodology (RSM). Nonlinear regression strategy in light of Gauss-Newton technique was utilized for modeling and optimization of the corrosion inhibition experiments. Second-order polynomial model was suggested to predict the corrosion rates as a function of four variables. The individual effect of temperature on corrosion rate was higher than the individual effects of inhibitor concentration, exposure time and rotational velocity, respectively. The interaction effects of independents variables were also addressed. Open circuit potential measurements were used as a significant way to gain information about the behavior of steel corrosion. Steady state potential was reached after one hour of immersion time. Mass loss results were in a good agreement with potentiodynamic polarization technique. Optimum inhibition efficiency was 95.9% at optimum operating conditions. Polarization plots revealed that the inhibitor acts as the anodic-type inhibitor.

Similar content being viewed by others

References

D. Oluyemi, O. Oluwole and B. Adewuyi, Mater. Res., 14, 135 (2011).

A. Oluwaseun and I. Simeon, Inter. Jr. Eng Res. Gen. Sci., 3, 1141 (2015).

S. Ghareba and S. Omanovic, Corros. Sci., 52, 2113 (2010).

A. Khadom, A. Yaro, A. Kadum, A. AlTaie and A. Musa, Am. J. Appl. Sci., 6, 1409 (2009).

A. Khadom and K. Hameed, Int. J. Chem. Technol., 4, 17 (2012).

A. Mahmood and A. Khadom, J. Fail. And. Preven., 16, 1071 (2016).

A. Fadhil, A. Khadom, H. Liu, C. Fu, J. Wang, N. Fadhil and H. Mahood, J Mol. Liq., 276, 503 (2019).

S. Ahmed, W. Ali and A. Khadom, J. Bio-and Tribo-Corrosion, 5, 15 (2019).

J. Trela and M. Scendo, Ochrona Przed Korozia, 55, 224 (2012).

A. Khadom, B. Abod, H. Mahood and A. Kadhum, J. Fail. Anal. Prev., 18, 1300 (2018).

X. Zhao, J. Yang and X. Fan, Appl. Mech. Mater, 44/47, 4066 (2011).

J. Trela, M. Chat and M. Scendo, CHEMIK, 69, 592 (2015).

T. Joanna, C. Milena and S. Mieczystaw, CHEMIK, 69, 599 (2015).

D. Silva, A. Mirapalheta, C. Martinez-Hurtle and J. Tonholo, Int. J. Eng. Technol, 14, 113 (2014).

G. Bueno, M. Taqueda, H. De Melo and I. C. Guedes, Brazilian J. Chem. Eng., 32, 177 (2015).

D. Bingol and S. Zor, Corrosion, 69, 462 (2013).

B. Nikrooz, H. Ebrahimifar and M. Zandrahimi, Indian J. Chem. Technol., 24, 162 (2017).

D. Granato, V. De Araujo Calado and B. Jarvis, Food Res. International, 55, 149 (2014).

B. Deniz and Z. Sibel, Corrosion, 69, 467 (2013).

A. Khadom and K. Rashid, World]. Eng., 15/3, 388 (2018).

L. Tarantino, Design and Analysis of Industrial Experiments, Tetra Pak (2010).

R. Marcus and E. Mansfeld, Analytical Methods in Corrosion Science and Engineering, 10th Ed., Taylor and Francis Group, New York (2006).

A. Khadom, Korean J. Chem. Eng., 30, 2204 (2013).

C. Jeff Wu and S. Michael, Experiments: Planning, Analysis and Optimization, 2nd Ed., John Wiley New York, USA (2009).

A.Y. Musa, A.A. Kadhum, A.B. Mohamad, A.R. Daud, M.S. Takriff and S.K. Kamarudin, Corros. Sci., 51, 2393 (2009).

A. Yaro, H. Al-Jendeel and A. Khadom, Desalination, 270, 193 (2011).

K. Rashid and A. Khadom, Anti-Corrosion Methods and Materials, 65, 514 (2018).

M. Cedeno, L. Vera and T. Pineda, J. Phys.: Conf. Series, 786 (2017).

L. Zhao, Y. He, X. Deng, G. Yang, W. Li, J. Liang and Q. Tang, Molecules, 17, 3618 (2012).

D. Thirumalaikumarasamy, V. Balasubramanian and S. Sabari, J. Mag nesium Alloys, 5, 133 (2017).

A. Musa, A. Kadhum, A. Mohamad, A. Daud, M. Takriff and S. Kamarudin, Corros. Sci., 51, 2393 (2009).

A. Yaro and A. Kahdom, Int. J. Surf. Sci. Eng., 4, 438 (2010).

H. Uhlig and R. Winston, Corrosion and Corrosion Control, 4th Ed., Wiley (2008).

A. Shams El Din, R. Mohammed and H. Haggag, Desalination, 114, 95 (1997).

F. De Souza, Corros. Sci., 51, 642 (2009).

Acknowledgement

The author would like to thank Department of Chemical Engineering/University of Technology/Baghdad/Iraq for support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rashid, K.H., Khadom, A.A. Optimization of inhibitive action of sodium molybdate (VI) for corrosion of carbon steel in saline water using response surface methodology. Korean J. Chem. Eng. 36, 1350–1359 (2019). https://doi.org/10.1007/s11814-019-0291-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-019-0291-1