Abstract

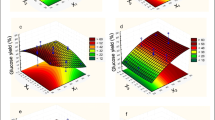

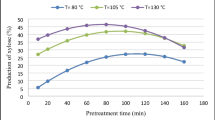

In converting advanced biomass to fuel, one pretreatment that has been extensively explored is a high temperature, dilute-sulfuric acid (H2SO4) process. This effectively hydrolyzes the hemicellulosic portion of the lignocellulosic biomass to fermentable sugars. Our aim was to optimize the concentration of sulfuric acid and residence time to release xylose from the hemicellulose of sugarcane bagasse. According to response surface methodology (RSM), the optimum concentrations and residence time were determined. The experimental maximum yield for xylose production was found to be 78.9% at 170 °C, 0.24% acid, for 15 min, and 76.4% at 200 °C, 0.22% acid, for 6 min. The predicted maximum yield obtained for the fitted model was found to be 80.3% and 78.1% for the conditions stated above, respectively. The experimental yield was around 1.5% lower than that of the predicted yield. It was confirmed in this study that pentose sugars (xylose and arabinose) derived from hemicellulose fraction were further degraded. The statistical optimization method, which incorporates reaction time, temperature and acid concentration, did prove to provide a useful means of trading off the combined effects of these three variables on total xylose recovery yields.

Similar content being viewed by others

References

A. Pandey, C. R. Soccol, P. Nigam and V. T. Soccol, Biores. Technol., 74, 69 (2000).

M. A. Ferrara, E. P. S. Bon and J. S. A. Neto, Appl. Biochem. Biotechnol., 98–100, 289 (2002).

C. M. Takahashi, K.G. C. Lima, D. F. Takahashi and F. Alterthum, World J. Microb. Biotechnol., 16, 829 (2000).

E. Frollini and M. J. A. Pimenta, Anais Assoc. Bras. Qu m., 46(1), 43 (1997).

A. Pessoa Jr., I.M. Mancilha and S. Sato, Brazilian J. Chem. Eng., 14, 291 (1997).

B. H. Um, B. Frideman and G. P. van Walsum, Holzforschung., 65, 51 (2011).

S.W. Baek, J. S. Kim, Y. K. Park, Y. S. Kim and K. K. Oh, Biotechnol. Biopro. Eng., 13, 332 (2008).

B. H. Um and G. P. van Walsum, Appl. Biochem. Biotechnol., 153, 127 (2009).

S. E. Jacobsen and C. E. Wyman, Appl. Biochem. Biotechnol., 84–86, 81 (2000).

S. Walton, G. P. van Walsum and A. van Heiningen, Bioresour. Technol., 101(6), 1935 (2009).

B. H. Um and G. P. van Walsum, Bioresour. Technol., 101, 5978 (2010).

H. C. Chen, Food Biotechnol., 10, 13 (1996).

M. Giovanni, Food Technol., 37, 96 (1983).

B. R. Cordenunsi, R. S. F. da Silva, K. C. Srivastava, S. Fabre-Sanches and M. A. Perre, J. Biotechnol., 2, 1 (1985).

P.V. Rao, K. Jayaraman and C. M. Lakshmanan, Process Biochem., 28, 391 (1993).

A. Sluiter, B. Hames, R. Ruiz, C. Scarlata, J. Sluiter, D. Templeton and D. Crocker, Determination of Sugars, Byproduct, and Degradation Products in Liquid Fraction Process Samples, NREL/TP-510-42623 (2008).

S. B. Kim, B. H. Um and S. C. Park, Appl. Biochem. Biotechnol., 91–93, 91 (2001).

B. H. Um, M.N. Karim and L. L. Henk, Appl. Biochem. Biotechnol., 105–108, 115 (2002).

B. H. Um and T. R. Hanley, Korean J. Chem. Eng., 25(5), 1094 (2008).

B. H. Um and G. P. van Walsum, Appl. Biochem. Biotechnol., 161, 432 (2010).

B. Sipos, J. Reczey, Z. Somorai, Z. Kadar, D. Dienes and K. Reczey, Appl. Biochem. Biotechnol., 153(1–23), 151 (2008).

T. S. Jeong, B. H. Um, J. S. Kim and K. K. Oh, Appl. Biochem. Biotechnol., 161, 22 (2010).

B. P. Lavarack, G. J. Griffin and D. Rodman, Biomass Bioenergy, 23, 367 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Um, BH., Bae, SH. Statistical methodology for optimizing the dilute acid hydrolysis of sugarcane bagasse. Korean J. Chem. Eng. 28, 1172–1176 (2011). https://doi.org/10.1007/s11814-011-0058-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-011-0058-9