Abstract

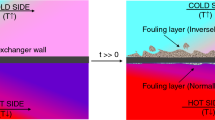

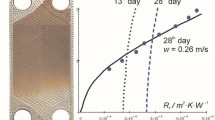

Heat exchangers are an important part of industrial processes as they handle a major portion of total energy consumption. Fouling could have serious impact on their performance and hence affect the economic performance of the process plant. The aim of this work was to simulate the crystallization fouling process in a heat exchanger by developing a C++ program and adopting UDF functions through Fluent software; and hence evaluate all the given models and consequently implement the model which would best suit our particular case. The finding of this work would enable us to evaluate the thickness and fouling rate in the heat exchangers. Furthermore, the effect of pulsating flow on the crystallization fouling of calcium sulfate (CaSO4) in the heat exchanger was also investigated, and the effect of operation of different amplitude of the oscillations (10–70) and frequencies (1.59–12.73 Hz) on the fouling of this compound was studied.

Similar content being viewed by others

References

A. Al-Haddad and N. Al-Binally, International Journal of Heat and Fluid Flow, 10, 131 (1989).

P. P. Grassmann and M. Tuma, International Journal of Heat and Mass Transfer, 22, 799 (1978).

X. Wang and N. Zhang, Journal of Heat and Mass Transfer, 48, 3957 (2005).

H. Gomaa and A. M. Al Taweel, Chem. Eng. J., 102, 71 (2004).

M. R. Mackley and P. Stonestreet, Chem. Eng. Sci., 50, 2211 (1995).

C. R. Brunold, J.C. B. Hunns, M. R. Mackley and J.W. Thompson, Chem. Eng. Sci., 44, 1227(1989).

T. Howes, M. R. Mackely and E. P. L. Roberts, Chem. Eng. Sci., 46, 1669 (1991).

S.A. Gbadebo, A. M. Said and M.A. Habib, Journal of Heat and Mass Transfer, 35, 377 (1999).

V. Pérez-Herranz, J. L. Guiñón and J. Garca-Antón, Chem. Eng. Sci., 54, 1667 (1999).

R. C. Martinelli, L. M. K. Boelter, E. B. Weinberg and S. Yakahi, Transactions of the American Society of Mechanical Engineers, 65, 789 (1943).

Z.X. Mao and T. J. Hanratty, Experiments in Fluids, 2, 129 (1985).

Z.X. Mao and T. J. Hanratty, Journal of Fluid Mechanics, 170, 545 (1986).

A. Velazquez, J. R. Arias and J. L. Montanes, International Journal of Heat and Mass Transfer, 52, 647 (2009).

F. Brahim, W. Augustin and M. Bohnet, International Journal of Thermal Sciences, 42, 323 (2003).

FLUENT 6.1, Users’s Guide.

J. Lammers, Diss. TU Berlin (1972).

M. Bohnet, W. Augustin and H. Hirsch, Influence of fouling layer shear strength on removal, United Engineering Foundation and Begell House, New York (1997).

F. Brahim, W. Augustin and M. Bohnet, ECI Conference on heat exchanger fouling and cleaning: Fundamentals and applications, 17 (2004).

Y. Chen and J. Zhao, ICEBO2006, Shenzhen, China HVAC technologies for energy efficiency, IV-6–IV-3 (2006).

A. Suksangpanomrung, S. Chungpaibulpatana and P. Promvonge, International Communications in Heat and Mass Transfer, 34, 829 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saghatoleslami, N., Salooki, M.K. & Armin, M.A. Prediction of thickness and fouling rate in pulsating flow heat exchangers, using FLUENT simulator. Korean J. Chem. Eng. 27, 96–103 (2010). https://doi.org/10.1007/s11814-009-0315-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-009-0315-3