Abstract

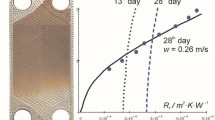

Plate heat exchanger is a widely used apparatus in the industrial production processes. Through a numerical simulation method, this paper calculates the deposition rate of CaSO4 fouling on heat transfer surfaces of the plate heat exchanger under saturation in the bulk. The effects of CaSO4 concentration in the range 0.7 kg/m3 to 1.5 kg/m3, inlet flow velocity under turbulent flow, and the fluid’s inlet temperature from 288 K to 328 K on the deposition rate, removal mass rate and fouling resistance are investigated. The simulation results are compared with the experimental results showing similar trend. The simulation results show that the concentration and the flow velocity affect significantly the fouling characteristics in the plate heat exchanger. The deposition mass rate, removal mass rate, and asymptotic value of fouling resistance all increase with the increase in CaSO4 concentration and the inlet temperature of the hot fluid, while the asymptotic value of fouling resistance decreases with the increasing of inlet flow velocity. The influence of the inlet temperature of cold fluid may be negligible.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer area of plate heat exchanger (m2)

- C :

-

Concentration (kg/m3)

- C b :

-

The concentration in the unit space (kg/m3)

- c F :

-

Concentration of CaSO4 in cold fluid

- C μ,C 1,C 2 :

-

Constant term

- c p :

-

Heat capacity at constant pressure (kJ·kg−1·K−1)

- D :

-

Diffusion coefficient

- d e :

-

Equivalent diameter (m)

- d p :

-

Average radius of CaSO4 crystals in the solution (μm)

- E :

-

Activation energy (kJ·kg−1·mol−1)

- f :

-

Friction factor

- g :

-

Acceleration of gravity (m/s2)

- h :

-

Overall heat transfer coefficient (W·m−2·K−1)

- I :

-

Turbulence intensity

- K m :

-

Mass transfer coefficient (m/s)

- k :

-

Turbulent kinetic energy

- k R :

-

Reaction rate constant

- k R0 :

-

Chemical reaction rate constant m4/(kg·s)

- k t :

-

Convective mass transfer coefficient (m/s)

- L :

-

Hydraulic diameter of import and export (m)

- L 0 :

-

Length of plate heat exchanger (m)

- l :

-

Characteristic length (m)

- m d :

-

Deposition rate (kg·m−2·s−1)

- m f :

-

Mass of fouling deposition on the unit heat exchanger area (kg/m2)

- m r :

-

Erosion rate (kg·m−2·s−1)

- Nu :

-

Nusselt number

- q :

-

Mass flow (kg/s)

- R :

-

Gas constant

- R f :

-

Fouling resistance (m2·K/W)

- R f * :

-

Asymptotic fouling resistance

- Sc :

-

Schmidt number

- Sh :

-

Sherwood number

- S ϕ :

-

General source item

- T :

-

Temperature (K)

- T C :

-

Cold fluid temperature (K)

- T H :

-

Hot fluid temperature (K)

- t :

-

Time (s)

- U :

-

Velocity vector

- u :

-

Velocity (m/s)

- V :

-

Fluid velocity (m/s)

- x f :

-

Thickness of fouling layer (mm)

- Γ ϕ :

-

Generalized diffusion coefficient

- Δp :

-

Pressure difference (Pa)

- ΔT :

-

Temperature difference (K)

- δ:

-

Linear expansion coefficient (W·m−1·K−1)

- ε :

-

Turbulent energy dissipation rate

- η :

-

Hydrodynamic viscosity coefficient

- η t :

-

Turbulent viscosity coefficient

- λ :

-

Thermal conductivity

- λ f :

-

Thermal conductivity of fouling layer W/(m·K)

- ρ :

-

Density (kg/m3)

- ρ f :

-

Average density of fouling layer (kg/m3)

- ϕ :

-

Generalized variable

- ψ :

-

Correction coefficient of temperature deviation

References

Wei L, Kan Z, Raj MM, Guan-Qiu L, Arthur EB (2016) Investigation of CaCO3 fouling in plate heat exchangers. Heat Mass Transf 52:2401–2414

Rios-Iribe EY, Cervantes-Gaxiola ME, Rubio-Castro E (2015) Heat transfer analysis of a non-Newtonian fluid flowing through a circular tube with twisted tape inserts. Appl Therm Eng 84:225–236

Vitillo F, Cachon L, Reulet P (2015) An innovative plate heat exchanger of enhanced compactness. Appl Therm Eng 87:826–838

Fratczak M, Nowak P, Czeczot J (2016) Simplified dynamical input–output modeling of plate heat exchangers–case study. Appl Therm Eng 98:880–893

Vijaya SG, Bengt S (2014) CFD simulation of heat transfer and pressure drop in compact brazed plate heat exchangers. Heat Transfer Eng 35:358–366

Sarraf K, Launay S, Tadrist L (2015) Complex 3D-flow analysis and corrugation angle effect in plate heat exchangers. Int J Therm Sci 94:126–138

Tabari ZT, Heris SZ (2015) Heat transfer performance of milk pasteurization plate heat exchangers using MWCNT/water nanofluid. J Dispers Sci Technol 36:196–204

Sarafraz MM, Hormozi F (2016) Heat transfer,pressure drop and fouling studies of multi-walled carbon nanotube nano-fluids inside a plate heat exchanger. Exp Thermal Fluid Sci 72:1–11

Jorge AWG, Pinto JM (2003) Modeling of plate heat exchangers with generalized configurations. Heat Mass Transf 46(3):2571–2585

Kern DQ, Seaton RE (1959) A theoretical analysis of thermal surface fouling. Br Chem Eng 4:258–262

Bansal B, Müller-Steinhagen H (1993) Crystallization fouling in plate heat exchangers. J Heat Transf 115:584–591

Wei L, Hongxia L, Guan-Qiu L (2013) Numerical and experimental analysis of composite fouling in corrugated plate heat exchangers. Int J Heat Mass Transf 63:351–360

Zettler HU, Wei M, Zhao Q, MÜller-Steinhagen H (2005) Influence of surface properties and characteristics on fouling in plate heat exchangers. Heat Transfer Eng 26:3–17

Chen WL, Yang YC, Lee HL (2009) Three-dimensional pipe fouling layer estimation by using conjugate gradient inverse method. Numer Heat Transfer 9:845–865

Grijspeerdt K, Hazarika B, Vucinic D (2003) Application of computational fluid dynamics to model the hydrodynamics of plate heat exchangers for milk processing. J Food Eng 57:237–242

Pääkkönen TM, Riihimäki M, Simonson CJ, Muurinen E, Keiski RL (2015) Modeling CaCO3 crystallization fouling on a heat exchanger surface-definition of fouling layer properties and model parameters. Int J Heat Mass Transf 83:84–98

Abd-Elhady M, Malayeri MR (2016) Transition of convective heat transfer to subcooled flow boiling due to crystallization fouling. Appl Therm Eng 92:122–129

Mwaba MG, Rindt CCM, Van Steenhoven AA (2006) Validated numerical analysis of CaSO4 fouling. Heat Transfer Eng 27:50–62

Konak AR (1974) A new model for surface reaction-controlled growth of crystals form solution. Chem Eng Sci 29:1537–1543

Brahim F, Augustin W, Bohnet M (2003) Numerical Simulation of the fouling process. Int J Therm Sci 42:323–334

Krause S (1993) Fouling of heat transfer surface by crystallization and sedimentation. Int Chem Eng 33:355–401

FLUENT Incorporated (2006) FLUENT 6.3 User’s Guide, Fluent Incorporated Lebanon NH, USA

Zhiming X, Jingtao W, Yuting J, Xiaoya G, Zuodong L (2016) Experimental study on microbial fouling characteristics of the plate heat exchanger. Appl Therm Eng 108:150–157

Acknowledgements

Authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (Grant No.51476025).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Z., Zhao, Y., Han, Z. et al. Numerical simulation of calcium sulfate (CaSO4) fouling in the plate heat exchanger. Heat Mass Transfer 54, 1867–1877 (2018). https://doi.org/10.1007/s00231-018-2282-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-018-2282-x