Abstract

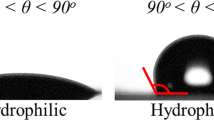

Wetting condition of micro/nanostructured surface has received tremendous attention due to the potential applications in commercial, industrial, and military areas. Surfaces with extreme wetting properties, e. g., superhydrophobic or superhydrophilic, are extensively employed due to their superior anti-icing, drag reduction, enhanced boiling heat transfer, self-cleaning, and anti-bacterial properties depending on solid-liquid interfacial interactions. Laser-based techniques have gained popularity in recent years to create micro/nano-structured surface owing to their high flexibility, system precision, and ease for automation. These techniques create laser induced periodic surface structures (LIPSS) or hierarchical structures on substrate material. However, micro/nanostructures alone cannot attain the desired wettability. Subsequent modification of surface chemistry is essentially needed to achieve target extreme wettability. This review paper aims to provide a comprehensive review for both laser texturing techniques and the following chemistry modification methods. Recent research progress and fundamental mechanisms of surface structure generation via different types of lasers and various chemistry modification methods are discussed. The complex combination between the laser texturing and surface chemistry modification methods to decide the final wetting condition is presented. More importantly, surface functionalities of these surfaces with extreme wetting properties are discussed. Lastly, prospects for future research are proposed and discussed.

摘要

微纳结构化表面的润湿特性因其在商业、工业和军事等领域的潜在应用而受到广泛关注。具有 极端润湿特性的表面,如超疏水或超亲水表面,已经实现了防冰、减阻、传热、自清洁和抗细菌等多种应用。基于激光的加工工艺具有高灵活性、系统准确性和高自动化程度等优点,在近些年成为了制备极端润湿性表面的一种新式方法。激光工艺可在表面上诱导出周期性表面结构或者多级微纳结构。然而,目标润湿性的实现不仅需要表面结构的改变,同时需要对表面化学进行适当的调控。本文综述了激光加工诱导表面结构改变和表面化学调控相结合以实现极端表面润湿性方面的最新研究进展。首先,介绍了激光工艺如何实现表面结构的改变,包括激光与材料相互作用的机理和不同激光加工方法如何诱导表面结构的产生。其次,介绍了调控激光加工表面化学改性的不同方法。然后,介绍了激光方法制备出的极端润湿性表面展现出的各种表面功能。最后,提出了该领域目前面临的问题和未来的展望。

Similar content being viewed by others

References

GAU H, HERMINGHAUS S, LENZ P, et al. Liquid morphologies on structured surfaces: From microchannels to microchips [J]. Science, 1999, 283(5398): 46–49. DOI: https://doi.org/10.1126/science.283.5398.46.

KHANNA R, NIGAM K D P. Partial wetting in porous catalysts: Wettability and wetting efficiency [J]. Chemical Engineering Science, 2002, 57(16): 3401–3405. DOI: https://doi.org/10.1016/S0009-2509(02)00211-7.

LAMPIN M, WAROCQUIER C, LEGRIS C, et al. Correlation between substratum roughness and wettability, cell adhesion, and cell migration [J]. Journal of Biomedical Materials Research, 1997, 36(1): 99–108. DOI: https://doi.org/10.1002/(sici)1097-4636(199707)36:1<99:aid-jbm12>3.0.co;2-e.

LAWRENCE J, HAO L, CHEW H R. On the correlation between Nd: YAG laser-induced wettability characteristics modification and osteoblast cell bioactivity on a titanium alloy [J]. Surface and Coatings Technology, 2006, 200(18–19): 5581–5589. DOI: https://doi.org/10.1016/j.surfcoat.2005.07.107.

VOROBYEV A, GUO Chun-lei. Making human enamel and dentin surfaces superwetting for enhanced adhesion [J]. Applied Physics Letters, 2011, 99: 193703. DOI: https://doi.org/10.1063/1.3660579.

KESHAV T R, BASU S. Spreading of liquid droplets on proton exchange membrane of a direct alcohol fuel cell [J]. Chemical Engineering Science, 2007, 62(24): 7515–7522. DOI: https://doi.org/10.1016/j.ces.2007.08.019.

PRABHU K N, FERNADES P, KUMAR G. Effect of substrate surface roughness on wetting behaviour of vegetable oils [J]. Materials & Design, 2009, 30(2): 297–305. DOI: https://doi.org/10.1016/j.matdes.2008.04.067.

ZHAO Xiu-cai, BLUNT M J, YAO Jun. Pore-scale modeling: Effects of wettability on waterflood oil recovery [J]. Journal of Petroleum Science and Engineering, 2010, 71(3–4): 169–178. DOI: https://doi.org/10.1016/j.petrol.2010.01.011.

SON Y, KIM C, YANG D H, et al. Spreading of an inkjet droplet on a solid surface with a controlled contact angle at low Weber and Reynolds numbers [J]. Langmuir, 2008, 24(6): 2900–2907. DOI: https://doi.org/10.1021/la702504v.

PERELAER J, HENDRIKS C E, DE LAAT A W M, et al. One-step inkjet printing of conductive silver tracks on polymer substrates [J]. Nanotechnology, 2009, 20(16): 165303. DOI: https://doi.org/10.1088/0957-4484/20/16/165303.

HABEDANK J B, GÜNTER F J, BILLOT N, et al. Rapid electrolyte wetting of lithium-ion batteries containing laser structured electrodes: In situ visualization by neutron radiography [J]. The International Journal of Advanced Manufacturing Technology, 2019, 102(9–12): 2769–2778. DOI: https://doi.org/10.1007/s00170-019-03347-4.

JEON D H. Wettability in electrodes and its impact on the performance of lithium-ion batteries [J]. Energy Storage Materials, 2019, 18: 139–147. DOI: https://doi.org/10.1016/j.ensm.2019.01.002.

PFLEGING W, PRÖLL J. A new approach for rapid electrolyte wetting in tape cast electrodes for lithium-ion batteries [J]. Journal of Materials Chemistry A, 2014, 36: 14918–14926. DOI: https://doi.org/10.1039/C4TA02353F.

SZUBZDA B, SZMAJA A, HALAMA A. Influence of structure and wettability of supercapacitor electrodes carbon materials on their electrochemical properties in water and organic solutions [J]. Electrochimica Acta, 2012, 86: 255–259. DOI: https://doi.org/10.1016/j.electacta.2012.08.060.

AVASTHI P, BALAKRISHNAN V. Tuning the wettability of vertically aligned CNT−TiO2 hybrid electrodes for enhanced supercapacitor performance [J]. Advanced Materials Interfaces, 2019, 6(6): 1801842.

QU Jun, BLAU P J, DAI Sheng, et al. Tribological characteristics of aluminum alloys sliding against steel lubricated by ammonium and imidazolium ionic liquids [J]. Wear, 2009, 267(5–8): 1226–1231. DOI: https://doi.org/10.1016/j.wear.2008.12.038.

QU Jun, CHI Miao-fang, MEYER H M, et al. Nanostructure and composition of tribo-boundary films formed in ionic liquid lubrication [J]. Tribology Letters, 2011, 43(2): 205–211. DOI: https://doi.org/10.1007/s11249-011-9800-z.

BAI W, ZHANG H, LIU B, et al. Effects of superu2010 absorbent polymers on the physical and chemical properties of soil following different wetting and drying cycles [J]. Soil Use and Management, 2010, 26(3): 253–260.

KOCH K, BHUSHAN B, BARTHLOTT W. Diversity of structure, morphology and wetting of plant surfaces [J]. Soft Matter, 2008, 4: 1943–1963. DOI: https://doi.org/10.1039/B804854A.

KOCH K, BHUSHAN B, BARTHLOTT W. Multifunctional surface structures of plants: An inspiration for biomimetics [J]. Progress in Materials Science, 2009, 54(2): 137–178. DOI: https://doi.org/10.1016/j.pmatsci.2008.07.003.

FENG X Q, GAO X, WU Z, et al. Superior water repellency of water strider legs with hierarchical structures: Experiments and analysis [J]. Langmuir, 2007, 23(9): 4892–4896. DOI: https://doi.org/10.1021/la063039b.

BARTHLOTT W, NEINHUIS C. Purity of the sacred lotus, or escape from contamination in biological surfaces [J]. Planta, 1997, 202(1): 1–8. DOI: https://doi.org/10.1007/s004250050096.

OTTEN A, HERMINGHAUS S. How plants keep dry: A physicist’s point of view [J]. Langmuir, 2004, 20(6): 2405–2408. DOI: https://doi.org/10.1021/la034961d.

GU Zhong-ze, UETSUKA H, TAKAHASHI K, et al. Structural color and the lotus effect [J]. Angewandte Chemie (International Ed in English), 2003, 42(8): 894–897. DOI: https://doi.org/10.1002/anie.200390235.

KINOSHITA S. Structural colors in the realm of nature [M]. Singapore: World Scientific, 2008.

E Jia-qiang, JIN Yu, DENG Yuan-wang, et al. Wetting models and working mechanisms of typical surfaces existing in nature and their application on superhydrophobic surfaces: A review [J]. Advanced Materials Interfaces, 2018, 5(1): 1701052.

SUN T, FENG L, GAO X, et al. Bioinspired surfaces with special wettability [J]. Accounts of Chemical Research, 2005, 38(8): 644–652.

FENG X, JIANG L. Design and creation of superwetting/antiwetting surfaces [J]. Advanced Materials, 2006, 18(23): 3063–3078.

EICK J D, JOHNSON L N, FROMER J R, et al. Surface topography: Its influence on wetting and adhesion in a dental adhesive system [J]. Journal of Dental Research, 1972, 51(3): 780–788. DOI: https://doi.org/10.1177/00220345720510031401.

PARK S J, SEO M K. Solid-liquid interface [C]//Interface Science and Composites. Amsterdam, The Netherlands, 2011, 18: 147–252.

KOCH K, BARTHLOTT W. Superhydrophobic and superhydrophilic plant surfaces: An inspiration for biomimetic materials [J]. Philosophical Transactions Series A: Mathematical, Physical, and Engineering Sciences, 2009, 367(1893): 1487–1509. DOI: https://doi.org/10.1098/rsta.2009.0022.

HE An, LIU Wen-wen, XUE Wei, et al. Nanosecond laser ablated copper superhydrophobic surface with tunable ultrahigh adhesion and its renewability with low temperature annealing [J]. Applied Surface Science, 2018, 434: 120–125. DOI: https://doi.org/10.1016/j.apsusc.2017.10.143.

BHUSHAN B, HER E. Fabrication of superhydrophobic surfaces with high and low adhesion inspired from rose petal [J]. Langmuir, 2010, 26(11): 8207–8217.

VOROBYEV A Y, GUO Chun-lei. Metal pumps liquid uphill [J]. Applied Physics Letters, 2009, 94(22): 224102. DOI: https://doi.org/10.1063/1.3117237.

VOROBYEV A Y, GUO Chun-lei. Water sprints uphill on glass [J]. Journal of Applied Physics, 2010, 108(12): 123512. DOI: https://doi.org/10.1063/1.3511431.

VOROBYEV A Y, GUO Chun-lei. Laser turns silicon superwicking [J]. Optics Express, 2010, 18(7): 6455–6460. DOI: https://doi.org/10.1364/OE.18.006455.

VOROBYEV A Y, GUO Chun-lei. Superwicking surfaces produced by femtosecond laser [J]. Advanced Lasers, 2015, 193: 101–115. DOI: https://doi.org/10.1007/978-94-017-9481-7_7.

SAMANTA A, WANG Qing-hua, SHAW S K, et al. Roles of chemistry modification for laser textured metal alloys to achieve extreme surface wetting behaviors [J]. Materials & Design, 2020, 192: 108744. DOI: https://doi.org/10.1016/j.matdes.2020.108744.

BOGOSLOV E A, DANILAEV M P, MIKHAILOV S A, et al. Energy efficiency of an integral anti-ice system based on fluoroplastic films [J]. Journal of Engineering Physics and Thermophysics, 2016, 89(4): 815–820. DOI: https://doi.org/10.1007/s10891-016-1441-5.

CAO L, JONES A K, SIKKA V K, et al. Anti-icing superhydrophobic coatings [J]. Langmuir, 2009, 25(21): 12444–12448. DOI: https://doi.org/10.1021/la902882b.

RUAN M, LI W, WANG B, et al. Preparation and anti-icing behavior of superhydrophobic surfaces on aluminum alloy substrates [J]. Langmuir, 2013, 29(27): 8482–8491. DOI: https://doi.org/10.1021/la400979d.

BOINOVICH L B, EMELYANENKO A M, EMELYANENKO K A, et al. Anti-icing properties of a superhydrophobic surface in a salt environment: An unexpected increase in freezing delay times for weak brine droplets [J]. Physical Chemistry Chemical Physics (PCCP), 2016, 18(4): 3131–3136. DOI: https://doi.org/10.1039/c5cp06988b.

JAGDHEESH R, DIAZ M, OCAÑA J. Bio-inspired self-cleaning ultrahydrophobic aluminium surface by laser processing [J]. RSC Advances, 2016, 6: 72933–72941. DOI: https://doi.org/10.1039/C6RA12236A.

VOROBYEV A Y, GUO Chun-lei. Multifunctional surfaces produced by femtosecond laser pulses [J]. Journal of Applied Physics, 2015, 117(3): 033103. DOI: https://doi.org/10.1063/1.4905616.

TA D V, DUNN A, WASLEY T J, et al. Nanosecond laser textured superhydrophobic metallic surfaces and their chemical sensing applications [J]. Applied Surface Science, 2015, 357: 248–254. DOI: https://doi.org/10.1016/j.apsusc.2015.09.027.

GOSE J W, GOLOVIN K, TUTEJA A, et al. Experimental investigation of turbulent skin-friction drag reduction using superhydrophobic surfaces [C]//31st Symposium on Naval Hydrodynamics, 2016(September): 11–16.

MIN T, KIM J. Effects of hydrophobic surface on skin-friction drag [J]. Physics of Fluids, 2004, 16(7): L55.

PU Xia, LI Guang-ji, HUANG Han-lu. Preparation, anti-biofouling and drag-reduction properties of a biomimetic shark skin surface [J]. Biology Open, 2016, 5(4): 389–396. DOI: https://doi.org/10.1242/bio.016899.

TRUESDELL R, MAMMOLI A, VOROBIEFF P, et al. Drag reduction on a patterned superhydrophobic surface [J]. Physical Review Letters, 2006, 97(4): 044504. DOI: https://doi.org/10.1103/PhysRevLett.97.044504.

RAUSCHER M, DIETRICH S. Wetting phenomena in nanofluidics [J]. Annual Review of Materials Research, 2008, 38(1): 143–172.

FARHADI S, FARZANEH M, KULINICH S A. Anti-icing performance of superhydrophobic surfaces [J]. Applied Surface Science, 2011, 257(14): 6264–6269. DOI: https://doi.org/10.1016/j.apsusc.2011.02.057.

FERRARI M, BENEDETTI A. Superhydrophobic surfaces for applications in seawater [J]. Advances in Colloid and Interface Science, 2015, 222: 291–304. DOI: https://doi.org/10.1016/j.cis.2015.01.005.

FERRARI M, BENEDETTI A, SANTINI E, et al. Biofouling control by superhydrophobic surfaces in shallow euphotic seawater [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2015, 480: 369–375. DOI: https://doi.org/10.1016/j.colsurfa.2014.11.009.

ZHANG Bin-bin, HU Xiu-hua, ZHU Qing-jun, et al. Controllable Dianthus caryophyllus-like superhydrophilic/superhydrophobic hierarchical structure based on self-congregated nanowires for corrosion inhibition and biofouling mitigation [J]. Chemical Engineering Journal, 2017, 312: 317–327. DOI: https://doi.org/10.1016/j.cej.2016.11.147.

ELLINAS K, TSEREPI A, GOGOLIDES E. Durable superhydrophobic and superamphiphobic polymeric surfaces and their applications: A review [J]. Advances in Colloid and Interface Science, 2017, 250: 132–157. DOI: https://doi.org/10.1016/j.cis.2017.09.003.

JAGGESSAR A, SHAHALI H, MATHEW A, et al. Biomimicking nano and micro-structured surface fabrication for antibacterial properties in medical implants [J]. Journal of Nanobiotechnology, 2017, 15(1): 64. DOI: https://doi.org/10.1186/s12951-017-0306-1.

TRIPATHY A, SREEDHARAN S, BHASKARLA C, et al. Enhancing the bactericidal efficacy of nanostructured multifunctional surface using an ultrathin metal coating [J]. Langmuir, 2017, 33(44): 12569–12579.

WANG Peng, QIU Ri, ZHANG Dun, et al. Fabricated superhydrophobic film with potentiostatic electrolysis method on copper for corrosion protection [J]. Electrochimica Acta, 2010, 56(1): 517–522. DOI: https://doi.org/10.1016/j.electacta.2010.09.017.

WANG Peng, ZHANG Dun, LU Zhou. Advantage of superhydrophobic surface as a barrier against atmospheric corrosion induced by salt deliquescence [J]. Corrosion Science, 2015, 90: 23–32. DOI: https://doi.org/10.1016/j.corsci.2014.09.001.

ZHANG Bin-bin, ZHAO Xia, LI Yan-tao, et al. Fabrication of durable anticorrosion superhydrophobic surfaces on aluminum substrates via a facile one-step electrodeposition approach [J]. RSC Advances, 2016, 6: 35455–35465. DOI: https://doi.org/10.1039/C6RA05484F.

NANAYAKKARA Y S, PERERA S, BINDIGANAVALE S, et al. The effect of AC frequency on the electrowetting behavior of ionic liquids [J]. Analytical Chemistry, 2010, 82(8): 3146–3154. DOI: https://doi.org/10.1021/ac9021852.

KESHAVARZ-MOTAMED Z, KADEM L, DOLATABADI A. Effects of dynamic contact angle on numerical modeling of electrowetting in parallel plate microchannels [J]. Microfluidics and Nanofluidics, 2009, 8(1): 47–56. DOI: https://doi.org/10.1007/s10404-009-0460-3.

IM Y, JOSHI Y, DIETZ C, et al. Enhanced boiling of a dielectric liquid on copper nanowire surfaces [J]. International Journal of Micro-nano Scale Transport, 2010, 1(1): 79–96.

LI Chen, WANG Zuan-kai, WANG P I, et al. Nanostructured copper interfaces for enhanced boiling [J]. Small (Weinheim an Der Bergstrasse, Germany), 2008, 4(8): 1084–1088. DOI: https://doi.org/10.1002/smll.200700991.

CHEN Ren-kun, LU Ming-chang, SRINIVASAN V, et al. Nanowires for enhanced boiling heat transfer [J]. Nano Letters, 2009, 9(2): 548–553. DOI: https://doi.org/10.1021/nl8026857.

ROMOLI L, MORONI F, KHAN M M A. A study on the influence of surface laser texturing on the adhesive strength of bonded joints in aluminium alloys [J]. CIRP Annals, 2017, 66(1): 237–240. DOI: https://doi.org/10.1016/j.cirp.2017.04.123.

LI Jian, YAN Long, LI Wei-jun, et al. Superhydrophilic-underwater superoleophobic ZnO-based coated mesh for highly efficient oil and water separation [J]. Materials Letters, 2015, 153: 62–65. DOI: https://doi.org/10.1016/j.matlet.2015.03.146.

JI S, RAMADHIANTI P A, NGUYEN T B, et al. Simple fabrication approach for superhydrophobic and superoleophobic Al surface [J]. Microelectronic Engineering, 2013, 111: 404–408. DOI: https://doi.org/10.1016/j.mee.2013.04.010.

SONG J, HUANG S, HU K, et al. Fabrication of superoleophobic surfaces on Al substrates [J]. Journal of Materials Chemistry A, 2013, 1(46): 14783–14789.

BARTHWAL S, KIM Y S, LIM S H. Mechanically robust superamphiphobic aluminum surface with nanopore-embedded microtexture [J]. Langmuir, 2013, 29(38): 11966–11974. DOI: https://doi.org/10.1021/la402600h.

BARTHWAL S, KIM Y S, LIM S H. Fabrication of amphiphobic surface by using titanium anodization for large-area three-dimensional substrates [J]. Journal of Colloid and Interface Science, 2013, 400: 123–129. DOI: https://doi.org/10.1016/j.jcis.2013.02.037.

CHOI H, CHOO S, SHIN J, et al. Fabrication of superhydrophobic and oleophobic surfaces with overhang structure by reverse nanoimprint lithography [J]. Journal of Physical Chemistry C, 2013, 117: 24354–24359. DOI: https://doi.org/10.1021/JP4070399.

HAYASE G, KANAMORI K, HASEGAWA G, et al. A superamphiphobic macroporous silicone monolith with marshmallow-like flexibility [J]. Angewandte Chemie, 2013, 52(41): 10788–10791. DOI: https://doi.org/10.1002/anie.201304169.

LI Y, ZHU X, ZHOU X, et al. A facile way to fabricate a superamphiphobic surface [J]. Applied Physics A: Materials Science and Processing, 2014, 115(3): 765–770.

DARMANIN T, GUITTARD F. Superoleophobic surfaces with short fluorinated chains [J]. Soft Matter, 2013, 9: 5982–5990. DOI: https://doi.org/10.1039/C3SM50643F.

BELLANGER H, DARMANIN T, GIVENCHY E T D, et al. Influence of intrinsic oleophobicity and surface structuration on the superoleophobic properties of PEDOP films bearing two fluorinated tails [J]. Journal of Materials Chemistry, 2013, 1: 2896–2903. DOI: https://doi.org/10.1039/C2TA00517D.

DARMANIN T, TARRADE J, CELIA E, et al. Superoleophobic meshes with high adhesion by electrodeposition of conducting polymer containing short perfluorobutyl chains [J]. Journal of Physical Chemistry C, 2014, 118: 2052–2057. DOI: https://doi.org/10.1021/JP410639J.

TARRADE J, DARMANIN T, GIVENCHY E T D, et al. Super liquid-repellent properties of electrodeposited hydrocarbon and fluorocarbon copolymers [J]. RSC Advances, 2013, 3: 10848–10853. DOI: https://doi.org/10.1039/C3RA40636A.

DRAME A, DARMANIN T, DIENG S, et al. Superhydrophobic and oleophobic surfaces containing wrinkles and nanoparticles of PEDOT with two short fluorinated chains [J]. RSC Advances, 2014, 4: 10935–10943. DOI: https://doi.org/10.1039/C3RA47479H.

KWON M H, SHIN H S, CHU C N. Fabrication of a superhydrophobic surface on metal using laser ablation and electrodeposition [J]. Applied Surface Science, 2014, 288: 222–228. DOI: https://doi.org/10.1016/j.apsusc.2013.10.011.

SUN Tao-lei, WANG Guo-jie, LIU Huan, et al. Control over the wettability of an aligned carbon nanotube film [J]. Journal of the American Chemical Society, 2003, 125(49): 14996–14997. DOI: https://doi.org/10.1021/ja038026o.

LIU Bin, JIANG Ge-dong, WANG Wen-jun, et al. Porous microstructures induced by picosecond laser scanning irradiation on stainless steel surface [J]. Optics and Lasers in Engineering, 2016, 78: 55–63. DOI: https://doi.org/10.1016/j.optlaseng.2015.10.003.

STRATAKIS E, BONSE J, HEITZ J, et al. Laser engineering of biomimetic surfaces [J]. Materials Science and Engineering R: Reports, 2020, 141: 100562. DOI: https://doi.org/10.1016/j.mser.2020.100562.

ALNASER A S, KHAN S A, GANEEV R A, et al. Recent advances in femtosecond laser-induced surface structuring for oil-water separation [J]. Applied Sciences, 2019, 9(8): 1554.

PAZOKIAN H, SELIMIS A, BARZIN J, et al. Tailoring the wetting properties of polymers from highly hydrophilic to superhydrophobic using UV laser pulses [J]. Journal of Micromechanics and Microengineering, 2012, 22(3): 035001.

GUPTA A, JOSHI M R, MAHATO N, et al. Superhydrophobic surfaces [M]//Biosurfaces: A Materials Science and Engineering Perspective, Wiley, 2015, 11: 170–200.

SAMAHA M A, TAFRESHI H V, GAD-EL-HAK M. Superhydrophobic surfaces: From the lotus leaf to the submarine [J]. Comptes Rendus Mécanique, 2012, 340(1–2): 18–34. DOI: https://doi.org/10.1016/j.crme.2011.11.002.

JEEVAHAN J, CHANDRASEKARAN M, BRITTO JOSEPH G, et al. Superhydrophobic surfaces: A review on fundamentals, applications, and challenges [J]. Journal of Coatings Technology and Research, 2018, 15(2): 231–250. DOI: https://doi.org/10.1007/s11998-017-0011-x.

SIMPSON J T, HUNTER S R, AYTUG T. Superhydrophobic materials and coatings: A review [J]. Reports on Progress in Physics, 2015, 78(8): 086501. DOI: https://doi.org/10.1088/0034-4885/78/8/086501.

BARATI DARBAND G, ALIOFKHAZRAEI M, KHORSAND S, et al. Science and engineering of superhydrophobic surfaces: Review of corrosion resistance, chemical and mechanical stability [J]. Arabian Journal of Chemistry, 2020, 13(1): 1763–1802. DOI: https://doi.org/10.1016/j.arabjc.2018.01.013.

MILIONIS A, LOTH E, BAYER I S. Recent advances in the mechanical durability of superhydrophobic materials [J]. Advances in Colloid and Interface Science, 2016, 229: 57–79. DOI: https://doi.org/10.1016/j.cis.2015.12.007.

YAN Y Y, GAO N, BARTHLOTT W. Mimicking natural superhydrophobic surfaces and grasping the wetting process: A review on recent progress in preparing superhydrophobic surfaces [J]. Advances in Colloid and Interface Science, 2011, 169(2): 80–105. DOI: https://doi.org/10.1016/j.cis.2011.08.005.

ZHANG P, LV F Y. A review of the recent advances in superhydrophobic surfaces and the emerging energy-related applications [J]. Energy, 2015, 82: 1068–1087. DOI: https://doi.org/10.1016/j.energy.2015.01.061.

DRELICH J, CHIBOWSKI E. Superhydrophilic and superwetting surfaces: Definition and mechanisms of control [J]. Langmuir, 2010, 26(24): 18621–18623. DOI: https://doi.org/10.1021/la1039893.

DRELICH J, CHIBOWSKI E, MENG D D, et al. Hydrophilic and superhydrophilic surfaces and materials [J]. Soft Matter, 2011, 7(21): 9804–9828. DOI: https://doi.org/10.1039/C1SM05849E.

ZHANG Ji-lin, SEVERTSON S J. Fabrication and use of artificial superhydrophilic surfaces [J]. Journal of Adhesion Science and Technology, 2014, 28(8–9): 751–768. DOI: https://doi.org/10.1080/01694243.2012.697725.

ZHANG Liang, ZHAO Ning, XU Jian. Fabrication and application of superhydrophilic surfaces: A review [J]. Journal of Adhesion Science and Technology, 2014, 28(8–9): 769–790. DOI: https://doi.org/10.1080/01694243.2012.697714.

OTITOJU T A, AHMAD A L, OOI B S. Superhydrophilic (superwetting) surfaces: A review on fabrication and application [J]. Journal of Industrial and Engineering Chemistry, 2017, 47: 19–40. DOI: https://doi.org/10.1016/j.jiec.2016.12.016.

VOROBYEV A Y, GUO Chun-lei. Femtosecond laser structuring of titanium implants [J]. Applied Surface Science, 2007, 253(17): 7272–7280. DOI: https://doi.org/10.1016/j.apsusc.2007.03.006.

VOROBYEV A Y, MAKIN V S, GUO Chun-lei. Periodic ordering of random surface nanostructures induced by femtosecond laser pulses on metals [J]. Journal of Applied Physics, 2007, 101(3): 034903. DOI: https://doi.org/10.1063/1.2432288.

MARTÍNEZ-CALDERON M, RODRÍGUEZ A, DIASPONTE A, et al. Femtosecond laser fabrication of highly hydrophobic stainless steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS [J]. Applied Surface Science, 2016, 374: 81–89. DOI: https://doi.org/10.1016/j.apsusc.2015.09.261.

RUKOSUYEV M V, LEE J, CHO S J, et al. One-step fabrication of superhydrophobic hierarchical structures by femtosecond laser ablation [J]. Applied Surface Science, 2014, 313: 411–417. DOI: https://doi.org/10.1016/j.apsusc.2014.05.224.

SIPE J E, YOUNG J F, PRESTON J S, et al. Laser-induced periodic surface structure I: Theory [J]. Physical Review B, 1983, 27(2): 1141–1154.

BONSE J, KRÜGER J, HÖHM S, et al. Femtosecond laser-induced periodic surface structures [J]. Jounral of Laser Applications, 2012, 24(4): 042006.

GARRELIE F, COLOMBIER J P, PIGEON F, et al. Evidence of surface plasmon resonance in ultrafast laser-induced ripples [J]. Optics Express, 2011, 19(10): 9035–9043. DOI: https://doi.org/10.1364/OE.19.009035.

HUANG Min, ZHAO Fu-li, CHENG Ya, et al. Origin of laser-induced near-subwavelength ripples: Interference between surface plasmons and incident laser [J]. ACS Nano, 2009, 3(12): 4062–4070. DOI: https://doi.org/10.1021/nn900654v.

MIYAJI G, MIYAZAKI K. Origin of periodicity in nanostructuring on thin film surfaces ablated with femtosecond laser pulses [J]. Optics Express, 2008, 16(20): 16265–16271. DOI: https://doi.org/10.1364/oe.16.016265.

BOROWIEC A, HAUGEN H K. Subwavelength ripple formation on the surfaces of compound semiconductors irradiated with femtosecond laser pulses [J]. Applied Physics Letters, 2003, 82(25): 4462–4464. DOI: https://doi.org/10.1063/1.1586457.

HENYK M, VOGEL N, WOLFFRAMM D, et al. Femtosecond laser ablation from dielectric materials: Comparison to arc discharge erosion [J]. Applied Physics A, 1999, 69(1): S355–S358. DOI: https://doi.org/10.1007/s003390051416.

REIF J, COSTACHE F, HENYK M, et al. Ripples revisited: Non-classical morphology at the bottom of femtosecond laser ablation craters in transparent dielectrics [J]. Applied Surface Science, 2002, 197–198: 891–895. DOI: https://doi.org/10.1016/S0169-4332(02)00450-6.

AHMMED K M T, GRAMBOW C A, KIETZIG A. Fabrication of micro/nano structures on metals by femtosecond laser micromachining [J]. Micromachines, 2014, 5: 1219–1253. DOI: https://doi.org/10.3390/mi5041219.

GNILITSKYI I, GRUZDEV V, BULGAKOVA N M, et al. Mechanisms of high-regularity periodic structuring of silicon surface by sub-MHz repetition rate ultrashort laser pulses [J]. Applied Physics Letters, 2016, 109(14): 143101. DOI: https://doi.org/10.1063/1.4963784.

TSIBIDIS G, BARBEROGLOU M, LOUKAKOS P, et al. Dynamics of ripple formation on silicon surfaces by ultrashort laser pulses in subablation conditions [J]. Physical Review B, 2011, 86: 115316. DOI: https://doi.org/10.1103/PhysRevB.86.115316.

TSIBIDIS G D, FOTAKIS C, STRATAKIS E. From ripples to spikes: A hydrodynamical mechanism to interpret femtosecond laser-induced self-assembled structures [J]. Physical Review B, 2015, 92(4): 041405.

CUNHA A, SERRO A P, OLIVEIRA V, et al. Wetting behaviour of femtosecond laser textured Ti−6Al−4V surfaces [J]. Applied Surface Science, 2013, 265: 688–696. DOI: https://doi.org/10.1016/j.apsusc.2012.11.085.

LI Bao-jia, LI Huang, HUANG Li-jing, et al. Femtosecond pulsed laser textured titanium surfaces with stable superhydrophilicity and superhydrophobicity [J]. Applied Surface Science, 2016, 389: 585–593. DOI: https://doi.org/10.1016/j.apsusc.2016.07.137.

STEELE A, BARADA K N, ALEXANDER D, et al. Linear abrasion of a titanium superhydrophobic surface prepared by ultrafast laser microtexturing [J]. Journal of Micromechanics and Microengineering, 2013, 23(11): 115012.

BALDACCHINI T, CAREY J E, ZHOU Ming, et al. Superhydrophobic surfaces prepared by microstructuring of silicon using a femtosecond laser [J]. Langmuir, 2006, 22(11): 4917–4919. DOI: https://doi.org/10.1021/la053374k.

HER T H, FINLAY R J, WU C, et al. Microstructuring of silicon with femtosecond laser pulses [J]. Applied Physics Letters, 1998, 73(12): 1673–1675. DOI: https://doi.org/10.1063/1.122241.

WU Bo, ZHOU Ming, LI Jian, et al. Superhydrophobic surfaces fabricated by microstructuring of stainless steel using a femtosecond laser [J]. Applied Surface Science, 2009, 256(1): 61–66. DOI: https://doi.org/10.1016/j.apsusc.2009.07.061.

MORADI S, KAMAL S, ENGLEZOS P, et al. Femtosecond laser irradiation of metallic surfaces: Effects of laser parameters on superhydrophobicity [J]. Nanotechnology, 2013, 24(41): 415302. DOI: https://doi.org/10.1088/0957-4484/24/41/415302.

KAM D, BHATTACHARYA S, MAZUMDER J. Control of the wetting properties of an AISI 316L stainless steel surface by femtosecond laser-induced surface modification [J]. Journal of Micromechanics and Microengineering, 2012, 22(10): 105019.

LONG Jiang-you, PAN Lin, FAN Pei-xun, et al. Cassie-state stability of metallic superhydrophobic surfaces with various micro/nanostructures produced by a femtosecond laser [J]. Langmuir, 2016, 32(4): 1065–1072. DOI: https://doi.org/10.1021/acs.langmuir.5b04329.

BIZI-BANDOKI P, BENAYOUN S, VALETTE S, et al. Modifications of roughness and wettability properties of metals induced by femtosecond laser treatment [J]. Applied Surface Science, 2011, 257(12): 5213–5218. DOI: https://doi.org/10.1016/j.apsusc.2010.12.089.

BIZI-BANDOKI P, VALETTE S, AUDOUARD E, et al. Time dependency of the hydrophilicity and hydrophobicity of metallic alloys subjected to femtosecond laser irradiations [J]. Applied Surface Science, 2013, 273: 399–407. DOI: https://doi.org/10.1016/j.apsusc.2013.02.054.

SKOULAS E, MANOUSAKI A, FOTAKIS C, et al. Biomimetic surface structuring using cylindrical vector femtosecond laser beams [J]. Scientific Reports, 2017, 7: 45114. DOI: https://doi.org/10.1038/srep45114.

SARBADA S, SHIN Y C. Superhydrophobic contoured surfaces created on metal and polymer using a femtosecond laser [J]. Applied Surface Science, 2017, 405: 465–475. DOI: https://doi.org/10.1016/j.apsusc.2017.02.019.

JAGDHEESH R, PATHIRAJ B, KARATAY E, et al. Laser-induced nanoscale superhydrophobic structures on metal surfaces [J]. Langmuir, 2011, 27(13): 8464–8469. DOI: https://doi.org/10.1021/la2011088.

LONG Jiang-you, FAN Pei-xun, ZHONG Min-lin, et al. Superhydrophobic and colorful copper surfaces fabricated by picosecond laser induced periodic nanostructures [J]. Applied Surface Science, 2014, 311: 461–467. DOI: https://doi.org/10.1016/j.apsusc.2014.05.090.

WANG Xing-sheng, LI Cheng-yu, HONG Wei, et al. Fabrication of ordered hierarchical structures on stainless steel by picosecond laser for modified wettability applications [J]. Optics Express, 2018, 26(15): 18998–19008. DOI: https://doi.org/10.1364/OE.26.018998.

MILLES S, DAHMS J, SOLDERA M, et al. Stable superhydrophobic aluminum surfaces based on laser-fabricated hierarchical textures [J]. Materials (Basel, Switzerland), 2021, 14(1): 184. DOI: https://doi.org/10.3390/ma14010184.

YANG Zhi-ru, ZHU Chong-chong, ZHENG Nan, et al. Superhydrophobic surface preparation and wettability transition of titanium alloy with micro/nano hierarchical texture [J]. Materials (Basel, Switzerland), 2018, 11(11): 2210. DOI: https://doi.org/10.3390/ma11112210.

NGUYEN H H, TIEU A K, WAN Shan-hong, et al. Surface characteristics and wettability of superhydrophobic silanized inorganic glass coating surfaces textured with a picosecond laser [J]. Applied Surface Science, 2021, 537: 147808. DOI: https://doi.org/10.1016/j.apsusc.2020.147808.

RAJAB F H, LIAUW C M, BENSON P S, et al. Picosecond laser treatment production of hierarchical structured stainless steel to reduce bacterial fouling [J]. Food and Bioproducts Processing, 2018, 109: 29–40. DOI: https://doi.org/10.1016/j.fbp.2018.02.009.

RAJAB F H, LIAUW C M, BENSON P S, et al. Production of hybrid macro/micro/nano surface structures on Ti6Al4V surfaces by picosecond laser surface texturing and their antifouling characteristics [J]. Colloids and Surfaces B: Biointerfaces, 2017, 160: 688–696. DOI: https://doi.org/10.1016/j.colsurfb.2017.10.008.

JAGDHEESH R. Fabrication of a superhydrophobic Al2O3 surface using picosecond laser pulses [J]. Langmuir, 2014, 30(40): 12067–12073. DOI: https://doi.org/10.1021/la5033527.

ZHANG Zhao-yang, GU Qin-ming, JIANG Wen, et al. Achieving of bionic super-hydrophobicity by electrodepositing nano-Ni-Pyramids on the picosecond laser-ablated micro-Cu-cone surface [J]. Surface and Coatings Technology, 2019, 363: 170–178. DOI: https://doi.org/10.1016/j.surfcoat.2019.02.037.

DING Shi-jie, ZHU De-hua, XUE Wei, et al. Picosecond laser-induced hierarchical periodic near- and deep-subwavelength ripples on stainless-steel surfaces [J]. Nanomaterials (Basel, Switzerland), 2019, 10(1): 62. DOI: https://doi.org/10.3390/nano10010062.

SUN Ke, YANG Huan, XUE Wei, et al. Anti-biofouling superhydrophobic surface fabricated by picosecond laser texturing of stainless steel [J]. Applied Surface Science, 2018, 436: 263–267. DOI: https://doi.org/10.1016/j.apsusc.2017.12.012.

RAJAB F H, WHITEHEAD D, LIU Zhu, et al. Characteristics of hierarchical micro/nano surface structure formation generated by picosecond laser processing in water and air [J]. Applied Physics B, 2017, 123(12): 1–12. DOI: https://doi.org/10.1007/s00340-017-6858-9.

WANG Xing-sheng, XU Bin, CHEN Yun-fu, et al. Fabrication of micro/nano-hierarchical structures for droplet manipulation via velocity-controlled picosecond laser surface texturing [J]. Optics and Lasers in Engineering, 2019, 122: 319–327. DOI: https://doi.org/10.1016/j.optlaseng.2019.06.021.

NGO C V, CHUN D M. Fast wettability transition from hydrophilic to superhydrophobic laser-textured stainless steel surfaces under low-temperature annealing [J]. Applied Surface Science, 2017, 409: 232–240. DOI: https://doi.org/10.1016/j.apsusc.2017.03.038.

PATIL D, ARAVINDAN S, WASSON M, et al. Fast fabrication of superhydrophobic titanium alloy as antibacterial surface using nanosecond laser texturing [J]. Journal of Micro and Nano-Manufacturing, 2018, 6: 011002. DOI: https://doi.org/10.1115/1.4038093.

QIAO Juan, ZHU Li-na, YUE Wen, et al. The effect of attributes of micro-shapes of laser surface texture on the wettability of WC-CrCo metal ceramic coatings [J]. Surface and Coatings Technology, 2018, 334: 429–437. DOI: https://doi.org/10.1016/j.surfcoat.2017.12.001.

TA V D, DUNN A, WASLEY T J, et al. Laser textured superhydrophobic surfaces and their applications for homogeneous spot deposition [J]. Applied Surface Science, 2016, 365: 153–159. DOI: https://doi.org/10.1016/j.apsusc.2016.01.019.

TA V D, DUNN A, WASLEY T J, et al. Laser textured surface gradients [J]. Applied Surface Science, 2016, 371: 583–589. DOI: https://doi.org/10.1016/j.apsusc.2016.03.054.

TANG M, SHIM V, PAN Z Y, et al. Laser ablation of metal substrates for super-hydrophobic effect [J]. Journal of Laser Micro Nanoengineering, 2011, 6(1): 6–9.

TANG Ming-kai, HUANG Xing-jiu, GUO Zheng, et al. Fabrication of robust and stable superhydrophobic surface by a convenient, low-cost and efficient laser marking approach [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2015, 484: 449–456. DOI: https://doi.org/10.1016/j.colsurfa.2015.08.029.

TANG Ming-kai, HUANG Xing-jiu, YU Jin-gui, et al. Simple fabrication of large-area corrosion resistant superhydrophobic surface with high mechanical strength property on TiAl-based composite [J]. Journal of Materials Processing Technology, 2017, 239: 178–186. DOI: https://doi.org/10.1016/j.jmatprotec.2016.08.024.

YAN Huang-ping, ABDUL RASHID M R B, KHEW S Y, et al. Realization of laser textured brass surface via temperature tuning for surface wettability transition [J]. Opto-Electronic Engineering, 2017(6): 587–592.

YAN Huang-ping, ABDUL RASHID M R B, KHEW S Y, et al. Wettability transition of laser textured brass surfaces inside different mediums [J]. Applied Surface Science, 2018, 427: 369–375. DOI: https://doi.org/10.1016/j.apsusc.2017.08.218.

YANG Z, TIAN Y L, YANG C J, et al. Modification of wetting property of Inconel 718 surface by nanosecond laser texturing [J]. Applied Surface Science, 2017, 414: 313–324. DOI: https://doi.org/10.1016/j.apsusc.2017.04.050.

BOINOVICH L B, MODIN E B, SAYFUTDINOVA A R, et al. Combination of functional nanoengineering and nanosecond laser texturing for design of superhydrophobic aluminum alloy with exceptional mechanical and chemical properties [J]. ACS Nano, 2017, 11(10): 10113–10123. DOI: https://doi.org/10.1021/acsnano.7b04634.

CAI Yu-kui, CHANG Wen-long, LUO Xi-chun, et al. Superhydrophobic structures on 316L stainless steel surfaces machined by nanosecond pulsed laser [J]. Precision Engineering, 2018, 52: 266–275. DOI: https://doi.org/10.1016/j.precisioneng.2018.01.004.

CARPEÑO D F, DICKINSON M, SEAL C, et al. Induced hydrophobicity in microu2010 and nanostructured nickel thin films obtained by ultraviolet pulsed laser treatment [J]. Physica Status Solidi A: Applications and Materials Science, 2016, 213(10): 2709–2713.

DONG Chang-sheng, GU Yu, ZHONG Min-lin, et al. Fabrication of superhydrophobic Cu surfaces with tunable regular micro and random nano-scale structures by hybrid laser texture and chemical etching [J]. Journal of Materials Processing Technology, 2011, 211(7): 1234–1240. DOI: https://doi.org/10.1016/j.jmatprotec.2011.02.007.

LI Bao-jia, HUANG Li-jing, REN Nai-fei, et al. Laser ablation processing of zinc sheets in hydrogen peroxide solution for preparing hydrophobic microstructured surfaces [J]. Materials Letters, 2016, 164: 384–387. DOI: https://doi.org/10.1016/j.matlet.2015.11.035.

LI Jing, ZHAO Shi-cai, DU Feng, et al. One-step fabrication of superhydrophobic surfaces with different adhesion via laser processing [J]. Journal of Alloys and Compounds, 2018, 739: 489–498. DOI: https://doi.org/10.1016/j.jallcom.2017.12.252.

WANG Jun-nan, GAO Long-yue, LI Yong-liang, et al. Experimental research on laser interference micro/nano fabrication of hydrophobic modification of stent surface [J]. Lasers in Medical Science, 2017, 32(1): 221–227. DOI: https://doi.org/10.1007/s10103-016-2105-6.

CHUN D M, NGO C V, LEE K M. Fast fabrication of superhydrophobic metallic surface using nanosecond laser texturing and low-temperature annealing [J]. CIRP Annals, 2016, 65(1): 519–522. DOI: https://doi.org/10.1016/j.cirp.2016.04.019.

CHEN Tian-chi, LIU Hong-tao, YANG Hai-feng, et al. Biomimetic fabrication of robust self-assembly superhydrophobic surfaces with corrosion resistance properties on stainless steel substrate [J]. RSC Advances, 2016, 6: 43937–43949. DOI: https://doi.org/10.1039/C6RA06500G.

NGO C V, CHUN D M. Control of laser-ablated aluminum surface wettability to superhydrophobic or superhydrophilic through simple heat treatment or water boiling post-processing [J]. Applied Surface Science, 2018, 435: 974–982. DOI: https://doi.org/10.1016/j.apsusc.2017.11.185.

FARSHCHIAN B, GATABI J R, BERNICK S M, et al. Scaling and mechanism of droplet array formation on a laser-ablated superhydrophobic grid [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2018, 547: 49–55. DOI: https://doi.org/10.1016/j.colsurfa.2018.03.026.

GARCIA-GIRON A, ROMANO J M, LIANG Y, et al. Combined surface hardening and laser patterning approach for functionalising stainless steel surfaces [J]. Applied Surface Science, 2018, 439: 516–524. DOI: https://doi.org/10.1016/j.apsusc.2018.01.012.

GREGORČIČ P, ŠETINA-BATIČ B, HOČEVAR M. Controlling the stainless steel surface wettability by nanosecond direct laser texturing at high fluences [J]. Applied Physics A, 2017, 123(12): 766. DOI: https://doi.org/10.1007/s00339-017-1392-5.

JAGDHEESH R, GARCÍA-BALLESTEROS J J, OCAÑA J L. One-step fabrication of near superhydrophobic aluminum surface by nanosecond laser ablation [J]. Applied Surface Science, 2016, 374: 2–11. DOI: https://doi.org/10.1016/j.apsusc.2015.06.104.

LUO B H, SHUM P W, ZHOU Z F, et al. Preparation of hydrophobic surface on steel by patterning using laser ablation process [J]. Surface and Coatings Technology, 2010, 204(8): 1180–1185. DOI: https://doi.org/10.1016/j.surfcoat.2009.10.043.

EHRHARDT M, HAN Bing, FROST F, et al. Generation of laser-induced periodic surface structures (LIPSS) in fused silica by single NIR nanosecond laser pulse irradiation in confinement [J]. Applied Surface Science, 2019, 470: 56–62. DOI: https://doi.org/10.1016/j.apsusc.2018.11.119.

SIMÕES J G A B, RIVA R, MIYAKAWA W. High-speed laser-induced periodic surface structures (LIPSS) generation on stainless steel surface using a nanosecond pulsed laser [J]. Surface and Coatings Technology, 2018, 344: 423–432. DOI: https://doi.org/10.1016/j.surfcoat.2018.03.052.

VEIKO V, KARLAGINA Y, MOSKVIN M, et al. Metal surface coloration by oxide periodic structures formed with nanosecond laser pulses [J]. Optics and Lasers in Engineering, 2017, 96: 63–67. DOI: https://doi.org/10.1016/j.optlaseng.2017.04.014.

CHEN Lei, LIU Ze-lin, GUO Chuan, et al. Nanosecond laser-induced controllable periodical surface structures on silicon [J]. Chinese Optics Letters, 2022(1): 186–191.

MILLES S, SOLDERA M, VOISIAT B, et al. Fabrication of superhydrophobic and ice-repellent surfaces on pure aluminium using single and multiscaled periodic textures [J]. Scientific Reports, 2019, 9: 13944. DOI: https://doi.org/10.1038/s41598-019-49615-x.

RAJAB F H, LIU Zhu, LI Lin. Long term superhydrophobic and hybrid superhydrophobic/superhydrophilic surfaces produced by laser surface micro/nano surface structuring [J]. Applied Surface Science, 2019, 466: 808–821. DOI: https://doi.org/10.1016/j.apsusc.2018.10.099.

WANG Chao, HUANG Hu, QIAN Yong-feng, et al. Nitrogen assisted formation of large-area ripples on Ti6Al4V surface by nanosecond pulse laser irradiation [J]. Precision Engineering, 2022, 73: 244–256. DOI: https://doi.org/10.1016/j.precisioneng.2021.09.012.

ZHAO Y, SU Y, HOU X, et al. Directional sliding of water: Biomimetic snake scale surfaces [J]. Opto-Electronic Advances, 2021, 4(4): 210008.

SU Yi-lin, ZHAO Yi-zhe, JIANG Sheng-yuan, et al. Anisotropic superhydrophobic properties of bioinspired surfaces by laser ablation of metal substrate inside water [J]. Advanced Materials Interfaces, 2021, 8(16): 2100555.

HUERTA-MURILLO D, AGUILAR-MORALES A I, ALAMRI S, et al. Fabrication of multi-scale periodic surface structures on Ti-6Al-4V by direct laser writing and direct laser interference patterning for modified wettability applications [J]. Optics and Lasers in Engineering, 2017, 98: 134–142. DOI: https://doi.org/10.1016/j.optlaseng.2017.06.017.

HUERTA-MURILLO D, GARCÍA-GIRÓN A, ROMANO J M, et al. Wettability modification of laser-fabricated hierarchical surface structures in Ti−6Al−4V titanium alloy [J]. Applied Surface Science, 2019, 463: 838–846. DOI: https://doi.org/10.1016/j.apsusc.2018.09.012.

SERLES P, NIKUMB S, BORDATCHEV E. Superhydrophobic and superhydrophilic functionalized surfaces by picosecond laser texturing [J]. Journal of Laser Applications, 2018, 30(3): 032505.

ZHENG Bu-xiang, JIANG Ge-dong, WANG Wen-jun, et al. Fabrication of superhydrophilic or superhydrophobic self-cleaning metal surfaces using picosecond laser pulses and chemical fluorination [J]. Radiation Effects and Defects in Solids, 2016, 171(5–6): 461–473. DOI: https://doi.org/10.1080/10420150.2016.1211658.

GUAN Y C, LUO F F, LIM G C, et al. Fabrication of metallic surfaces with long-term superhydrophilic property using one-stop laser method [J]. Materials & Design, 2015, 78: 19–24. DOI: https://doi.org/10.1016/j.matdes.2015.04.021.

RAZI S, MADANIPOUR K, MOLLABASHI M. Improving the hydrophilicity of metallic surfaces by nanosecond pulsed laser surface modification [J]. Journal of Laser Applications, 2015, 27: 042006. DOI: https://doi.org/10.2351/1.4928290.

RAJAB F H, LIU Zhu, LI Lin. Production of stable superhydrophilic surfaces on 316L steel by simultaneous laser texturing and SiO2 deposition [J]. Applied Surface Science, 2018, 427: 1135–1145. DOI: https://doi.org/10.1016/j.apsusc.2017.08.122.

TSENG S F, HSIAO W T, CHEN Ming-fei, et al. Surface wettability of silicon substrates enhanced by laser ablation [J]. Applied Physics A, 2010, 101(2): 303–308. DOI: https://doi.org/10.1007/s00339-010-5821-y.

CARDOSO J T, GARCIA-GIRÓN A, ROMANO J M, et al. Influence of ambient conditions on the evolution of wettability properties of an IR-, ns-laser textured aluminium alloy [J]. RSC Advances, 2017, 7(63): 39617–39627.

LONG Jiang-you, ZHONG Min-lin, ZHANG Hong-jun, et al. Superhydrophilicity to superhydrophobicity transition of picosecond laser microstructured aluminum in ambient air [J]. Journal of Colloid and Interface Science, 2015, 441: 1–9. DOI: https://doi.org/10.1016/j.jcis.2014.11.015.

BOINOVICH L B, EMELYANENKO A M, EMELYANENKO K A, et al. Comment on “Nanosecond laser textured superhydrophobic metallic surfaces and their chemical sensing applications” by Duong V. Ta, Andrew Dunn, Thomas J. Wasley, Robert W. Kay, Jonathan Stringer, Patrick J. Smith, Colm Connaughton, Jonathan D. Shephard (Appl. Surf. Sci. 357 (2015) 248–254) [J]. Applied Surface Science, 2016, 379: 111–113. DOI: https://doi.org/10.1016/j.apsusc.2016.04.056.

LAWRENCE J, WAUGH D. Creating superhydrophobic surface structures via the rose petal effect on stainless steel with a picosecond laser [J]. Lasers in Engineering, 2017, 37: 125–134.

LONG Jiang-you, FAN Pei-xun, GONG Ding-wei, et al. Superhydrophobic surfaces fabricated by femtosecond laser with tunable water adhesion: From lotus leaf to rose petal [J]. ACS Applied Materials & Interfaces, 2015, 7(18): 9858–9865. DOI: https://doi.org/10.1021/acsami.5b01870.

WANG Qing-hua, WANG Hui-xin. Tuning water adhesion of superhydrophobic surface by way of facile laser-chemical hybrid process [J]. Surface Innovations, 2021: 2100042.

BRASSARD J, SARKAR D, PERRON J. Fluorine based superhydrophobic coatings [J]. Applied Sciences, 2012, 2: 453–464. DOI: https://doi.org/10.3390/APP2020453.

SUBRAMANIAN B, KIM N, LEE W, et al. Surface modification of droplet polymeric microfluidic devices for the stable and continuous generation of aqueous droplets [J]. Langmuir, 2011, 27(12): 7949–7957. DOI: https://doi.org/10.1021/la200298n.

ACHOUR A, ISLAM M, SOLAYMANI S, et al. Influence of plasma functionalization treatment and gold nanoparticles on surface chemistry and wettability of reactive-sputtered TiO2 thin films [J]. Applied Surface Science, 2018, 458: 678–685. DOI: https://doi.org/10.1016/j.apsusc.2018.07.145.

KHARITONOV A P, KHARITONOVA L N. Surface modification of polymers by direct fluorination: A convenient approach to improve commercial properties of polymeric articles [J]. Pure and Applied Chemistry, 2009, 81: 451–471. DOI: https://doi.org/10.1351/PAC-CON-08-06-02.

CHANG F, CHENG S, HONG S J, et al. Superhydrophilicity to superhydrophobicity transition of CuO nanowire films [J]. Applied Physics Letters, 2010, 96: 114101. DOI: https://doi.org/10.1063/1.3360847.

ZORBA V, STRATAKIS E, BARBEROGLOU M, et al. Biomimetic artificial surfaces quantitatively reproduce the water repellency of a lotus leaf [J]. Advanced Materials, 2008, 20(21): 4049–4054.

NGO C V, CHUN D. Effect of heat treatment temperature on the wettability transition from hydrophilic to superhydrophobic on Laseru2010Ablated metallic surfaces [J]. Advanced Engineering Materials, 2018, 20(7): 1701086.

O’GARA J E, ALDEN B A, GENDREAU C A, et al. Dependence of cyano bonded phase hydrolytic stability on ligand structure and solution pH [J]. Journal of Chromatography A, 2000, 893(2): 245–251. DOI: https://doi.org/10.1016/S0021-9673(00)00696-8.

HORCAJADA P, RÁMILA A, FÉREY G, et al. Influence of superficial organic modification of MCM-41 matrices on drug delivery rate [J]. Solid State Sciences, 2006, 8(10): 1243–1249. DOI: https://doi.org/10.1016/j.solidstatesciences.2006.04.016.

LIU Nian, YAO Yan, CHA J J, et al. Functionalization of silicon nanowire surfaces with metal-organic frameworks [J]. Nano Research, 2012, 5(2): 109–116. DOI: https://doi.org/10.1007/s12274-011-0190-1.

WANG Qing-hua, SAMANTA A, SHAW S K, et al. Nanosecond laser-based high-throughput surface nanostructuring (nHSN) [J]. Applied Surface Science, 2020, 507: 145136. DOI: https://doi.org/10.1016/j.apsusc.2019.145136.

LOU Rui, LI Guang-ying, WANG Xu, et al. Antireflective and superhydrophilic structure on graphite written by femtosecond laser [J]. Micromachines, 2021, 12(3): 236. DOI: https://doi.org/10.3390/mi12030236.

VOROBYEV A Y, GUO Chun-lei. Colorizing metals with femtosecond laser pulses [J]. Applied Physics Letters, 2008, 92(4): 041914. DOI: https://doi.org/10.1063/1.2834902.

PAPADOPOULOS A, SKOULAS E, MIMIDIS A, et al. Biomimetic omnidirectional antireflective glass via direct ultrafast laser nanostructuring [J]. Advanced Materials (Deerfield Beach, Fla), 2019, 31(32): e1901123. DOI: https://doi.org/10.1002/adma.201901123.

NAYAK B K, GUPTA M C. Self-organized micro/nano structures in metal surfaces by ultrafast laser irradiation [J]. Optics and Lasers in Engineering, 2010, 48(10): 940–949. DOI: https://doi.org/10.1016/j.optlaseng.2010.04.010.

VOROBYEV A Y, GUO Chun-lei. Reflection of femtosecond laser light in multipulse ablation of metals [J]. Journal of Applied Physics, 2011, 110(4): 043102. DOI: https://doi.org/10.1063/1.3620898.

VOROBYEV A Y, GUO Chun-lei. Enhanced absorptance of gold following multipulse femtosecond laser ablation [J]. Physical Review B — Condensed Matter and Materials Physics, 2005, 72(19): 195422.

VOROBYEV A Y, TOPKOV A N, GURIN O V, et al. Enhanced absorption of metals over ultrabroad electromagnetic spectrum [J]. Applied Physics Letters, 2009, 95(12): 121106. DOI: https://doi.org/10.1063/1.3227668.

OU Zhi-gui, HUANG Min, ZHAO Fu-li. The fluence threshold of femtosecond laser blackening of metals: The effect of laser-induced ripples [J]. Optics & Laser Technology, 2016, 79: 79–87. DOI: https://doi.org/10.1016/j.optlastec.2015.11.018.

HUANG M, ZHAO F, CHENG Y, et al. The morphological and optical characteristics of femtosecond laser-induced large-area micro/nanostructures on GaAs, Si, and brass [J]. Optics Express, 2010, 18(Suppl 4): A600–A619. DOI: https://doi.org/10.1364/oe.18.00a600.

YANG Yang, YANG Jian-jun, LIANG Chun-yong, et al. Ultra-broadband enhanced absorption of metal surfaces structured by femtosecond laser pulses [J]. Optics Express, 2008, 16(15): 11259–11265. DOI: https://doi.org/10.1364/oe.16.011259.

BOINOVICH L B, EMELYANENKO A M, MODESTOV A D, et al. Synergistic effect of superhydrophobicity and oxidized layers on corrosion resistance of aluminum alloy surface textured by nanosecond laser treatment [J]. ACS Applied Materials & Interfaces, 2015, 7(34): 19500–19508. DOI: https://doi.org/10.1021/acsami.5b06217.

WANG Zhi-guo, SONG Jin-peng, WANG Tian-yi, et al. Laser texturing for superwetting titanium alloy and investigation of its erosion resistance [J]. Coatings, 2021, 11(12): 1547.

de LARA L R, JAGDHEESH R, OCAÑA J L. Corrosion resistance of laser patterned ultrahydrophobic aluminium surface [J]. Materials Letters, 2016, 184: 100–103. DOI: https://doi.org/10.1016/j.matlet.2016.08.022.

LANARA C, MIMIDIS A, STRATAKIS E. Femtosecond laser fabrication of stable hydrophilic and anti-corrosive steel surfaces [J]. Materials (Basel, Switzerland), 2019, 12(20): 3428. DOI: https://doi.org/10.3390/ma12203428.

FADEEVA E, TRUONG V K, STIESCH M, et al. Bacterial retention on superhydrophobic titanium surfaces fabricated by femtosecond laser ablation [J]. Langmuir, 2011, 27(6): 3012–3019. DOI: https://doi.org/10.1021/la104607g.

HASSEBROOK A, LUCIS M J, SHIELD J E, et al. Thermal stability of rare earth oxide coated superhydrophobic microstructured metallic surfaces [C]//Proceedings of the ASME 2015 13th International Conference on Nanochannels, Microchannels, and Minichannels (ICNMM2015). San Francisco, California, USA. 2015: 1–7.

LIN Yi, HAN Jin-peng, CAI Ming-yong, et al. Durable and robust transparent superhydrophobic glass surfaces fabricated by a femtosecond laser with exceptional water repellency and thermostability [J]. Journal of Materials Chemistry, 2018, 6: 9049–9056. DOI: https://doi.org/10.1039/C8TA01965G.

DARMANIN T, GUITTARD F. Recent advances in the potential applications of bioinspired superhydrophobic materials [J]. Journal of Materials Chemistry A, 2014, 39: 16319–16359. DOI: https://doi.org/10.1039/C4TA02071E.

WU Jun-rui, YIN Kai, LI Ming, et al. Under-oil self-driven and directional transport of water on a femtosecond laser-processed superhydrophilic geometry-gradient structure [J]. Nanoscale, 2020, 12(6): 4077–4084. DOI: https://doi.org/10.1039/c9nr09902f.

WU Zhi-peng, YIN Kai, WU Jun-rui, et al. Water droplet rapid spreading transport on femtosecond laser-treated photothermal and superhydrophilic surface [J]. Optics & Laser Technology, 2021, 141: 107099. DOI: https://doi.org/10.1016/j.optlastec.2021.107099.

KIRNER S V, HERMENS U, MIMIDIS A, et al. Mimicking bug-like surface structures and their fluid transport produced by ultrashort laser pulse irradiation of steel [J]. Applied Physics A: Materials Science and Processing, 2017, 123(12): 754.

PARADISANOS I, FOTAKIS C, ANASTASIADIS S H, et al. Gradient induced liquid motion on laser structured black Si surfaces [J]. Applied Physics Letters, 2015, 107(11): 111603. DOI: https://doi.org/10.1063/1.4930959.

XIE Fei, YANG Jian-jun, NGO C V. The effect of femtosecond laser fluence and pitches between V-shaped microgrooves on the dynamics of capillary flow [J]. Results in Physics, 2020, 19: 103606. DOI: https://doi.org/10.1016/j.rinp.2020.103606.

FANG Ran-ran, LI Ze-kai, ZHANG Xian-hang, et al. Spreading and drying dynamics of water drop on hot surface of superwicking Ti-6Al-4V alloy material fabricated by femtosecond laser [J]. Nanomaterials (Basel, Switzerland), 2021, 11(4): 899. DOI: https://doi.org/10.3390/nano11040899.

FANG Ran-ran, ZHANG Xian-hang, ZHENG Jian-gen, et al. Superwicking functionality of femtosecond laser textured aluminum at high temperatures [J]. Nanomaterials (Basel, Switzerland), 2021, 11(11): 2964. DOI: https://doi.org/10.3390/nano11112964.

SONG Yu-xin, WANG Cong, DONG Xin-ran, et al. Controllable superhydrophobic aluminum surfaces with tunable adhesion fabricated by femtosecond laser [J]. Optics & Laser Technology, 2018, 102: 25–31. DOI: https://doi.org/10.1016/j.optlastec.2017.12.024.

YONG J, CHEN F, YANG Q, et al. Femtosecond laser weaving superhydrophobic patterned pdms surfaces with tunable adhesion [J]. Journal of Physical Chemistry C, 2013, 117(47): 24907–24912.

STRATAKIS E, RANELLA A, FOTAKIS C. Biomimetic micro/nanostructured functional surfaces for microfluidic and tissue engineering applications [J]. Biomicrofluidics, 2011, 5(1): 13411. DOI: https://doi.org/10.1063/1.3553235.

STRATAKIS E, MATEESCU A, BARBEROGLOU M, et al. From superhydrophobicity and water repellency to superhydrophilicity: Smart polymer-functionalized surfaces [J]. Chemical Communications (Cambridge, England), 2010, 46(23): 4136–4138. DOI: https://doi.org/10.1039/c003294h.

PAPADOPOULOU E, BARBEROGLOU M, ZORBA V, et al. Reversible photoinduced wettability transition of hierarchical ZnO structures [J]. Journal of Physical Chemistry C, 2009, 113: 2891–2895. DOI: https://doi.org/10.1021/JP8085057.

WANG Qing-hua, WANG Hui-xin, ZHU Zhi-xian, et al. Switchable wettability control of titanium via facile nanosecond laser-based surface texturing [J]. Surfaces and Interfaces, 2021, 24: 101122. DOI: https://doi.org/10.1016/j.surfin.2021.101122.

WANG Qing-hua, CHENG Yang-yang, ZHU Zhi-xian, et al. Modulation and control of wettability and hardness of Zr-based metallic glass via facile laser surface texturing [J]. Micromachines, 2021, 12(11): 1322. DOI: https://doi.org/10.3390/mi12111322.

DOMKE M, SONDEREGGER G, KOSTAL E, et al. Transparent laser-structured glasses with superhydrophilic properties for anti-fogging applications [J]. Applied Physics A, 2019, 125(10): 1–10. DOI: https://doi.org/10.1007/s00339-019-2953-6.

ZUPANČIČ M, STEINBÜCHER M, GREGORČIČ P, et al. Enhanced pool-boiling heat transfer on laser-made hydrophobic/superhydrophilic polydimethylsiloxane-silica patterned surfaces [J]. Applied Thermal Engineering, 2015, 91: 288–297. DOI: https://doi.org/10.1016/j.applthermaleng.2015.08.026.

JALIL S A, ELKABBASH M, ZIHAO LI, et al. Multipronged heat-exchanger based on femtosecond laser-nano/microstructured Aluminum for thermoelectric heat scavengers [J]. Nano Energy, 2020, 75: 104987. DOI: https://doi.org/10.1016/j.nanoen.2020.104987.

SINGH S C, ELKABBASH M, LI Zi-long, et al. Solar-trackable super-wicking black metal panel for photothermal water sanitation [J]. Nature Sustainability, 2020, 3: 938–946. DOI: https://doi.org/10.1038/s41893-020-0566-x.

Funding

Project(52105175) supported by the National Natural Science Foundation of China; Project(BK20210235) supported by the Natural Science Foundation of Jiangsu Province, China; Project(JSSCBS20210121) supported by the Jiangsu Provincial Innovative and Entrepreneurial Doctor Program, China

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributors

WANG Qing-hua conducted the literature review and wrote the first draft of the manuscript. WANG Hui-xin supervised the research work and edited the draft of manuscript.

Conflict of interest

WANG Qing-hua and WANG Hui-xin declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, Qh., Wang, Hx. Laser surface functionalization to achieve extreme surface wetting conditions and resultant surface functionalities. J. Cent. South Univ. 29, 3217–3247 (2022). https://doi.org/10.1007/s11771-022-5140-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5140-4