Abstract

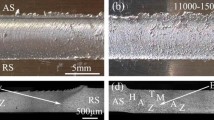

The extruded plate of powder metallurgy AA2024 aluminum alloy was successfully solid-state joined by friction stir welding (FSW) to demonstrate potential applications in the aerospace and automotive industries. For determining the optimal processing parameters of FSW, the microstructure, mechanical properties, and fracture behavior of FSW joints were evaluated. When the processing parameters were optimized with 2000 r/min rotation speed and 100 mm/min traverse speed, high quality welds were achieved. The ultimate tensile strength yield strength and elongation of the joint can reach 415 MPa (85% of the base metal strength), 282 MPa, and 9.5%, respectively. The hardness of the joint gradually decreased from the alloy matrix to the heat-affected zone. The lowest strength and hardness appeared near the heat-affected zone because of the over-aging caused by heat flow from repeated stirring during FSW. The average grain size of the stir zone (2.15 µm) was smaller than that of the base metal (4.43 µm) and the heat-affected zone (5.03 µm), whose grains had <110> preferred orientation.

摘要

本文通过搅拌摩擦焊(FSW)成功实现了粉末冶金AA2024铝合金挤压板材的焊接, 在航空航天、 汽车工业领域具有重要应用前景. 为了确定FSW的最佳加工参数, 对FSW接头的微观结构、 力学性能和断裂行为进行研究. 结果表明, 当搅拌速度为2000 r/min、焊接速度为100 mm/min时, 获得最优焊接接头性能, 其抗拉强度、 屈服强度和伸长率分别为415 MPa(母材强度的85%)、 282 MPa和9.5%. 焊接接头的硬度从合金基体到热影响区逐渐降低. 由于FSW过程中反复搅拌产生热量, 样品发生过时效, 导致热影响区附近的强度和硬度最低. 搅拌区的平均晶粒尺寸(2.15 µm)小于母材(4.43 µm)和热影响区(5.03 µm), 并且热影响区晶粒具有<110>择优取向.

Similar content being viewed by others

References

HUO Shu-hai, MAIS B. Characteristics of heat resistant nanoquasicrystalline PM aluminum materials [J]. Metal Powder Report, 2017, 72(1): 45–50. DOI: https://doi.org/10.1016/j.mprp.2016.07.003.

STEEDMAN G, BISHOP D P, CALEY W F, et al. Surface porosity investigation of aluminum-silicon PM alloys [J]. Powder Technology, 2012, 226: 225–230. DOI: https://doi.org/10.1016/j.powtec.2012.04.049.

CHEN Cun-guang, LI Feng, HAN Wei-hao, et al. Thermally stable Al conductor prepared from Al powder with a low oxygen content [J]. Materials Science and Engineering A, 2021, 813: 141174. DOI: https://doi.org/10.1016/j.msea.2021.141174.

SWEET G A W, AMIRKHIZ B S, WILLIAMS B W, et al. Microstructural evolution of a forged 2xxx series aluminum powder metallurgy alloy [J]. Materials Characterization, 2019, 151: 342–350. DOI: https://doi.org/10.1016/j.matchar.2019.03.033.

WANG Tao, HUANG Yu-feng, YANG Lun, et al. Microstructure and mechanical properties of 7055 Al alloy prepared under different sintering conditions using powder by-products [J]. Materials Science and Engineering A, 2021, 805: 140562. DOI: https://doi.org/10.1016/j.msea.2020.140562.

MANN R E D, HEXEMER R L, DONALDSON I W, et al. Hot deformation of an Al−Cu−Mg Powder metallurgy alloy [J]. Materials Science and Engineering A, 2011, 528(16, 17): 5476–5483. DOI: https://doi.org/10.1016/j.msea.2011.03.081.

BOLAND C D, HEXEMER R L, DONALDSON I W, et al. Industrial processing of a novel Al−Cu−Mg powder metallurgy alloy [J]. Materials Science and Engineering A, 2013, 559: 902–908. DOI: https://doi.org/10.1016/j.msea.2012.09.049.

CHEN Cun-guang, HAN Wei-hao, QI Miao, et al. Microstructural evolution and mechanical properties of an ultrahigh-strength Al−Zn−Mg−Cu alloy via powder metallurgy and hot extrusion [J]. Journal of Central South University, 2021, 28(4): 1195–1205. DOI: https://doi.org/10.1007/s11771-021-4669-y.

REN Jian, WANG Ri-chu, FENG Yan, et al. Microstructure evolution and mechanical properties of an ultrahigh strength Al−Zn−Mg−Cu−Zr-Sc (7055) alloy processed by modified powder hot extrusion with post aging [J]. Vacuum, 2019, 161: 434–442. DOI: https://doi.org/10.1016/j.vacuum.2019.01.013.

HU Lian-xi, LIU Zu-yan, WANG Er-de. Microstructure and mechanical properties of 2024 aluminum alloy consolidated from rapidly solidified alloy powders [J]. Materials Science and Engineering A, 2002, 323(1, 2): 213–217. DOI: https://doi.org/10.1016/S0921-5093(01)01348-X.

GRAYSON G N, SCHAFFER G B, GRIFFITHS J R. Observations of oxide films on fatigue fracture surfaces of a sintered 2xxx series aluminium alloy [J]. Materials Science and Engineering A, 2007, 454–455: 99–103. DOI: https://doi.org/10.1016/j.msea.2006.11.012.

ZHANG Chao, WAN Yang-jie, ZOU Wen-jun, et al. Composition optimization for Al−Zn−Mg−Cu alloys based on thermodynamics and first-principles calculations [J]. Computational and Theoretical Chemistry, 2021, 1201: 113293. DOI: https://doi.org/10.1016/j.comptc.2021.113293.

SO H, WON S J, PARK J, et al. Mechanical properties and microstructural evolution in Al−Cu−Mg−Ag alloy with a CuxMgx/10 content [J]. Materials Science and Engineering A, 2021, 824: 141573. DOI: https://doi.org/10.1016/j.msea.2021.141573.

GÜLERYÜZ G. Relationship between FSW parameters and hardness of the ferritic steel joints: Modeling and optimization [J]. Vacuum, 2020, 178: 109449. DOI: https://doi.org/10.1016/j.vacuum.2020.109449.

KAUSHIK P, KUMAR DWIVEDI D. Induction preheating in FSW of Al-steel combination [J]. Materials Today: Proceedings, 2021, 46: 1091–1095. DOI: https://doi.org/10.1016/j.matpr.2021.01.438.

RAMANA G V, YELAMASETTI B, VARDHAN T V. Effect of FSW process parameters and tool profile on mechanical properties of AA5082 and AA6061 welds [J]. Materials Today: Proceedings, 2021, 46: 826–830. DOI: https://doi.org/10.1016/j.matpr.2020.12.801.

G V R, SANKE N. Evaluation of tensile and microstructure-properties of AA2014 and AA7075 FSW weldments developed by HSS-10%Co and WC tools [J]. Materials Today: Proceedings, 2021, 46: 913–918. DOI: https://doi.org/10.1016/j.matpr.2021.01.060.

KASAI H, MORISADA Y, FUJII H. Dissimilar FSW of immiscible materials: Steel/magnesium [J]. Materials Science and Engineering A, 2015, 624: 250–255. DOI: https://doi.org/10.1016/j.msea.2014.11.060.

MOHAMMADZADEH JAMALIAN H, TAMJIDI ESKANDAR M, CHAMANARA A, et al. An artificial neural network model for multi-pass tool pin varying FSW of AA5086-H34 plates reinforced with Al2O3 nanoparticles and optimization for tool design insight [J]. CIRP Journal of Manufacturing Science and Technology, 2021, 35: 69–79. DOI: https://doi.org/10.1016/j.cirpj.2021.05.007.

EIVANI A R, VAFAEENEZHAD H, JAFARIAN H R, et al. A novel approach to determine residual stress field during FSW of AZ91 Mg alloy using combined smoothed particle hydrodynamics/neuro-fuzzy computations and ultrasonic testing [J]. Journal of Magnesium and Alloys, 2021, 9(4): 1304–1328. DOI: https://doi.org/10.1016/j.jma.2020.11.018.

TIAN Wen-ming, LI Song-mei, CHEN Xin, et al. Intergranular corrosion of spark plasma sintering assembled bimodal grain sized AA7075 aluminum alloys [J]. Corrosion Science, 2016, 107: 211–224. DOI: https://doi.org/10.1016/j.corsci.2016.02.034.

KUMAR N, DAS A, PRASAD S B. An analysis of friction stir welding (FSW) of metal matrix composites (MMCs) [J]. Materials Today: Proceedings, 2020, 26: 2650–2656. DOI: https://doi.org/10.1016/j.matpr.2020.02.558.

NARENTHIRAN B, PARANTHAMAN P. Investigations on effect of FSW process parameter on hybrid Al MMC using Taguchi approach [J]. Materials Today: Proceedings, 2021, 37: 759–763. DOI: https://doi.org/10.1016/j.matpr.2020.05.787.

SACHINKUMAR, NARENDRANATH S, CHAKRADHAR D. Effect of FSW on microstructure and hardness of AA6061/SiC/fly ash MMCs [J]. Materials Today: Proceedings, 2018, 5(9): 17866–17872. DOI: https://doi.org/10.1016/j.matpr.2018.06.113.

TAO Xi-chen, CHANG Yong-qin, GUO Yuan-hang, et al. Microstructure and mechanical properties of friction stir welded oxide dispersion strengthened AA6063 aluminum matrix composites enhanced by post-weld heat treatment [J]. Materials Science and Engineering A, 2018, 725: 19–27. DOI: https://doi.org/10.1016/j.msea.2018.03.094.

CHEN Cun-guang, WANG Wen-wen, GUO Zhi-meng, et al. Annealing effects on microstructure and mechanical properties of ultrafine-grained Al composites reinforced with nano-Al2O3 by rotary swaging [J]. Journal of Materials Engineering and Performance, 2018, 27(4): 1738–1745. DOI: https://doi.org/10.1007/s11665-018-3301-2.

SERCOMBE T B, SCHAFFER G B. On the role of magnesium and nitrogen in the infiltration of aluminium by aluminium for rapid prototyping applications [J]. Acta Materialia, 2004, 52(10): 3019–3025. DOI: https://doi.org/10.1016/j.actamat.2004.03.004.

AVETTAND-FÈNOËL M N, SIMAR A, SHABADI R, et al. Characterization of oxide dispersion strengthened copper based materials developed by friction stir processing [J]. Materials & Design, 2014, 60: 343–357. DOI: https://doi.org/10.1016/j.matdes.2014.04.012.

BREWER L N, BENNETT M S, BAKER B W, et al. Characterization of residual stress as a function of friction stir welding parameters in oxide dispersion strengthened (ODS) steel MA956 [J]. Materials Science and Engineering A, 2015, 647: 313–321. DOI: https://doi.org/10.1016/j.msea.2015.09.020.

BALOG M, OROVCIK L, NAGY S, et al. To what extent does friction-stir welding deteriorate the properties of powder metallurgy Al? [J]. Journal of Materials Research and Technology, 2020, 9(3): 6733–6744. DOI: https://doi.org/10.1016/j.jmrt.2020.04.087.

NOSKO M, ŠTEPÁNEK M, ZIFČÁK P, et al. Solid-state joining of powder metallurgy Al−Al2O3 nanocomposites via friction-stir welding: Effects of powder particle size on the weldability, microstructure, and mechanical property [J]. Materials Science and Engineering A, 2019, 754: 190–204. DOI: https://doi.org/10.1016/j.msea.2019.03.074.

KHODABAKHSHI F, YAZDABADI H G, KOKABI A H, et al. Friction stir welding of a P/M Al−Al2O3 nanocomposite: Microstructure and mechanical properties [J]. Materials Science and Engineering A, 2013, 585: 222–232. DOI: https://doi.org/10.1016/j.msea.2013.07.062.

WANG Tao, YANG Lun, TANG Zhao-feng, et al. Effect of aging treatment on microstructure, mechanical and corrosion properties of 7055 aluminum alloy prepared using powder by-product [J]. Materials Science and Engineering A, 2021, 822: 141606. DOI: https://doi.org/10.1016/j.msea.2021.141606.

WANG Tao, HUANG Yu-feng, YANG Lun, et al. Microstructure and mechanical properties of 7055 Al alloy prepared under different sintering conditions using powder by-products [J]. Materials Science and Engineering A, 2021, 805: 140562. DOI: https://doi.org/10.1016/j.msea.2020.140562.

SHANMUGASUNDARAM T, HEILMAIER M, MURTY B S, et al. On the Hall-Petch relationship in a nanostructured Al−Cu alloy [J]. Materials Science and Engineering A, 2010, 527(29, 30): 7821–7825. DOI: https://doi.org/10.1016/j.msea.2010.08.070.

HUANG Tian-lin, SHUAI Lin-fei, WAKEEL A, et al. Strengthening mechanisms and Hall-Petch stress of ultrafine grained Al−0.3%Cu [J]. Acta Materialia, 2018, 156: 369–378. DOI: https://doi.org/10.1016/j.actamat.2018.07.006.

HANSEN N. Hall-Petch relation and boundary strengthening [J]. Scripta Materialia, 2004, 51(8): 801–806. DOI: https://doi.org/10.1016/j.scriptamat.2004.06.002.

TAN Qi-yang, ZHANG Jing-qi, SUN Qiang, et al. Inoculation treatment of an additively manufactured 2024 aluminium alloy with titanium nanoparticles [J]. Acta Materialia, 2020, 196: 1–16. DOI: https://doi.org/10.1016/j.actamat.2020.06.026.

BADINI C, MARINO F, VERNÉ E. Calorimetric study on precipitation path in 2024 alloy and its SiC composite [J]. Materials Science and Engineering A, 1995, 191(1, 2): 185–191. DOI: https://doi.org/10.1016/0921-5093(94)09637-C.

YOUSEFI SHIVYARI S, HOSSEINI MONAZZAH A. Study on the balance between FSW parameters and heat treatment for an optimized Al2024-T8 joint: Microstructural and tensile evaluations [J]. Production Engineering, 2021, 15(5): 595–603. DOI: https://doi.org/10.1007/s11740-021-01054-2.

MUHAMMAD W, HUSAIN W, TAUQIR A, et al. Assessment of microstructure and mechanical properties of friction stir welded AA2014-O and AA2014-T6 sheets [J]. The International Journal of Advanced Manufacturing Technology, 2021, 115(7, 8): 2255–2267. DOI: https://doi.org/10.1007/s00170-021-07249-2.

YADAV V K, GAUR V, SINGH I V. Effect of post-weld heat treatment on mechanical properties and fatigue crack growth rate in welded AA-2024 [J]. Materials Science and Engineering A, 2020, 779: 139116. DOI: https://doi.org/10.1016/j.msea.2020.139116.

Author information

Authors and Affiliations

Contributions

HAN Wei-hao and CHEN Cun-guang conducted the literature review and wrote the draft of the manuscript. LI Pei, LIU Nan, DONG Shi-peng, GUO Zhi-meng, YANG Fang and SUI Yan-li analyzed the measured data. CHEN Cun-guang provided the concept and edited the draft of manuscript. VOLINSKY Alex A modified the English language of the manuscript. All authors replied to reviewers’ comments and revised the final version.

Corresponding author

Ethics declarations

HAN Wei-hao, LI Pei, LIU Nan, CHEN Cun-guang, DONG Shi-peng, GUO Zhi-meng, YANG Fang, SUI Yan-li and VOLINSKY Alex A. declare that they have no conflict of interest.

Additional information

Foundation item: Project(92066205) supported by the National Natural Science Foundation of China; Project(JCKY61420052008) supported by the National Defense Science and Technology Key Laboratory Foundation, China; Project(311021013) supported by Innovation Group Project of Southern Marine Science and Engineering Guangdong Laboratory (Zhuhai), China; Project(FRF-MP-20-52) supported by the Fundamental Research Funds for the Central Universities, China; Project(075-15-2021-612) support from the Government of the Russian Federation

Rights and permissions

About this article

Cite this article

Han, Wh., Li, P., Liu, N. et al. Microstructure and mechanical properties of friction stir welded powder metallurgy AA2024 alloy. J. Cent. South Univ. 29, 871–882 (2022). https://doi.org/10.1007/s11771-022-4962-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4962-4