Abstract

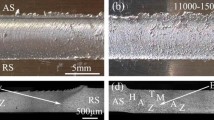

A 3.2 mm thin-walled 2219 aluminum alloy hemisphere shell was successfully fabricated by friction stir welding (FSW) combined with spinning and subsequent T6 treatment. The microstructural characteristics and the mechanical properties of the spun FSWed alloy were investigated. The results showed that the differences in microstructure of the base material and the joint were greatly improved during the spinning process, which consisted of fine dynamic recrystallization (DRX) grains with an average grain size of 4.7 μm and 6.6 μm, respectively. The microstructure and the mechanical properties of the joint were similar to the base material. After the solid solution, the uniformly distributed θ phase particles were greatly dissolved in the Al matrix and the growth of the grains was promoted. Besides, the dislocation densities were significantly decreased. However, a large quantity of needle-like θ′ phase precipitates evenly distributed in the matrix after T6 treatment. Moreover, the strengths were further improved to 291.6 MPa and 331.8 MPa after T6 treatment due to the high density of θ′ precipitates by hindering the dislocation movement.

Similar content being viewed by others

References

Y.C. Lin, L.T. Li, Y.C. Xia, and Y.Q. Jiang, Hot Deformation and Processing Map of a Typical Al-Zn-Mg-Cu Alloy, J. Alloys Compd., 2013, 550, p 438-445.

K. Surekha, B.S. Murty, and K.P. Rao, Microstructural Characterization and Corrosion Behavior of Multipass Friction Stir Processed AA2219 Aluminum Alloy, Surf. Coat. Technol., 2008, 202, p 4057-4068.

T. Dursun and C. Soutis, Recent Developments in Advanced Aircraft Aluminum Alloys, Mater. Des., 2014, 56, p 862-871.

S.J. Hales, W.A. Tayon, and E.K. Hoffman, AGG Suppression in Friction-Stir-Welded, Spin-Formed Al-Li 2195 Materials; Presentation at the Friction Stir Welding and Processing VI Symposium, TMS Annual Meeting, San Diego, CA, March (2011)

S.J. Hales and W.A. Tayon, Heat Treatment of a Friction-Stir-Welded and Spin-Formed Al-Li Alloy, Proc. Eng., 2011, 10, p 2496-2501.

C. Genevois, A. Deschamps, A. Denquin, and B. DoisneauCottignies, Quantitative Investigation of Precipitation and Mechanical Behaviour for AA2024 Friction Stir Welds, Acta Mater., 2005, 53(8), p 2447-2458.

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R, 2005, 50, p 1-78.

R. Nandan, T. DebRoy, and H.K.D.H. Bhadeshia, Recent Advances in Friction-Stir Welding—Process, Weldment Structure and Properties, Prog. Mater. Sci., 2008, 53(6), p 980-1023.

Y.C. Chen and K. Nakata, Friction Stir Lap Joining Aluminum and Magnesium Alloys, Scr. Mater., 2008, 58(6), p 433-436.

M. Bakkiyaraj, S. Stephen Bernard, G. Saikrishnan, S. Guruyogesh, T.G. Guruprasanna, and K. Dineshkumar, Effect of Tool Offset Condition on Mechanical and Metallurgical Properties of FSW Dissimilar Al-Cu Joint, Mater. Today Proc., 2021, 43, p 824-827.

Y.G. Hao and W. Liu, Analysis on Exceptional Cryogenic Mechanical Properties of AA2219 Alloy FSW Joints in Multi-scale, Mater. Sci. Eng. A, 2022, 850, p 143489.

N. Kamp, A. Sullivan, R. Tomasi, and J.D. Robson, Modelling of Heterogeneous Precipitate Distribution Evolution during Friction Stir Welding Process, Acta Mater., 2006, 54, p 2003-2014.

G. Buffa, G. Campanile, L. Fratini, and A. Prisco, Friction Stir Welding of Lap Joints: Influence of Process Parameters on the Metallurgical and Mechanical Properties, Mater. Sci. Eng. A, 2009, 519, p 19-26.

K. Kumar, S.V. Kailas, and T.S. Srivatsan, Influence of Tool Geometry in Friction Stir Welding, Mater. Manuf. Process., 2008, 23, p 188-194.

G. Buffa, J. Hua, R. Shivpuri, and L. Fratini, Design of the Friction Stir Welding Tool using the Continuum Based FEM Model, Mater. Sci. Eng. A, 2006, 419, p 381-388.

T.S. Srivatsan, S. Vasudevan, L. Park, and R.J. Lederich, The High Cycle Fatigue and Fracture Behavior of Friction Stir Welded Aluminum Alloy 2024, KEM, 2008, 378-379, p 175-206.

T.S. Liu, F. Qiu, H.Y. Yang, S. Liu, Q.C. Jiang, and L.C. Zhang, Exploring the Potential of FSW-ed Al-Zn-Mg-Cu-Based Composite Reinforced by Trace In-Situ Nanoparticles in Manufacturing Workpiece with Customizable Size and High Mechanical Performances, Compos. B, 2023, 250, p 110425.

P. Asadi, M.R.M. Aliha, M. Akbari, D.M. Imani, and F. Berto, Multivariate Optimization of Mechanical and Microstructural Properties of Welded Joints by FSW Method, Eng. Fail. Anal., 2022, 140, p 106528.

A.R. Hossein, V.T. Farid, and A.S.S. Mohammad, Creep Lifetime of Al 6061-T6 Pressurized Rotating Friction Stir Welded Tube Subjected to Internal Pressure and Rotational Velocity: Welding and Creep Lifetime Optimization, Int. J. Press. Vessels Pip., 2023, 202, p 104914.

X.W. Zhu, Y. Deng, Y. Lai, Y.F. Guo, Z.A. Yang, L. Fu, G.F. Xu, and J.W. Huang, Effects of Al3(Sc1-xZrx) Nano-Particles on Microstructure and Mechanical Properties of Friction-Stir-Welded Al-Mg-Mn Alloys, Trans. Nonferrous Met. Soc. China, 2023, 33, p 25-35.

S.J. Yuan, Z.L. Hu, and X.S. Wang, Evaluation of Formability and Material Characteristics of Aluminum Alloy Friction Stir Welded Tube Produced by a Novel Process, Mater. Sci. Eng. A, 2012, 543, p 210-216.

F. Dong, Y.P. Yi, S.Q. Huang, H.L. He, J.W. Huang, C.G. Wang, and K. Huang, Refinement of Second-Phase Particles and Grain Structures of 2219 Al-Cu Alloy Forgings using an Improved Thermomechanical Treatment Process, Mater. Character., 2021, 173, p 110927.

Z.H. Wang, Y.F. Gao, J.L. Huang, C.D. Wu, G.L. Wang, and J. Liu, Precipitation Phenomena and Strengthening Mechanism of Al-Cu Alloys Deposited by In-Situ Rolled Wire-Arc Additive Manufacturing, Mater. Sci. Eng. A, 2022, 855, p 143770.

B. Bellon, S. Haouala, and J. Llorca, An Analysis of the Influence of the Precipitate Type on the Mechanical Behavior of Al-Cu Alloys by Means of Micropillar Compression Tests, Acta Mater., 2020, 194, p 207-223.

A.M. Richard, S. Kevin, B. Sumit, F.A. Lawrence, B.W. Karla, D.P. Jonathan, N.L. Donovan, R.D. Ryan, P. Alex, and S. Amit, Microstructural Evolution and Strengthening Mechanisms in a Heat-Treated Additively Manufactured Al-Cu-Mn-Zr Alloy, Mater. Sci. Eng. A, 2022, 840, p 142928.

H. Gao, Y. Huang, W. Nix, and J. Hutchinson, Mechanism-Based Strain Gradient Plasticity—I, Theory, J. Mech. Phys. Solids, 1999, 47(6), p 1239-1263.

L.P. Kubin and A. Mortensen, Geometrically Necessary Dislocations and Strain-Gradient Plasticity: A Few Critical Issues, Scr. Mater., 2003, 48(2), p 119-125.

D. Liu, D. Wu, G. Ma, C. Zhong, F. Niu, A. Gasser, J.H. Schleifenbaum, and G. Bi, Effect of Post-Deposition Heat Treatment on Laser-TIG Hybrid Additive Manufactured Al-Cu Alloy, Virtual Phys. Prototyp., 2020, 15(4), p 445-459.

Z.X. Li, M. Zhan, X.G. Fan, X.X. Wang, and F. Ma, Age Hardening Behaviors of Spun 2219 Aluminum Alloy Component, J. Mater. Res. Technol., 2020, 9(3), p 4706-4716.

X. Mao, Y. Yi, H. He, S. Huang, and W. Guo, Second Phase Particles and Mechanical Properties of 2219 Aluminum Alloys Processed by an Improved Ring Manufacturing Process, Mater. Sci. Eng. A, 2020, 781, p 139226.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chang, Z.L., Huang, M.H., Wang, X.B. et al. Microstructural Characteristics and Mechanical Properties of Friction Stir Welded 2219 Aluminum Alloy Plate After Spinning and Heat Treatment. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09438-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09438-y