Abstract

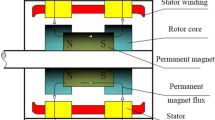

To meet the requirements of high performance, low cost, and easy operation of the robot, a brushless motor drive and control system for the robot joint is designed, including CAN bus, WPF upper host computer development, and magnetic encoders, and other sensors, in which the STM32F103 chip is used as the main control chip, and the DRV8323 is a brushless motor drive chip. The principle of field-oriented control (FOC) brushless motor drive is elaborated. Meanwhile, the drive and control system design is completed from both hardware and software aspects. Finally, the PID algorithm is used for the closed-loop speed test of the robot joint. The experimental result shows that the designed robot joints and control system run smoothly and reliably, have the characteristics of modularization and miniaturization, and are suitable for the control of micro-service robots and manipulators.

摘要

为满足机器人高性能、低成本、易操作等要求, 采用STM32F103芯片作为主控芯片, DRV8323 为无刷电机驱动芯片, 结合CAN总线、WPF上位机开发, 以及磁编码器等传感器, 设计了机器人关 节刷电机驱动及控制系统。详细阐述了磁场定向控制(FOC)无刷电机驱动的原理, 从硬件和软件两 方面完成驱动与控制系统设计。运用PID 算法对机器人关节进行转速闭环测试, 实验表明所设计的机 器人关节与控制系统运行平稳可靠, 具有模块化、小型化的特点, 适用于微型服务机器人和机械手的 控制。

Similar content being viewed by others

References

RAMASAMY M, SOMASUNDRAM R, RAMASAMY A. dSPACE real time implementation of fuzzy PID position controller for vertical rotating single link arm robot using four-quadrant BLDC drive [J]. Acta Scientiarum-Technology, 2017, 39(3): 301–311. DOI: https://doi.org/10.4025/actascitechnol.v39i3.28416.

WU W D, WU Y L, LI J H, REN X G, SHI D X, TANG Y H. Multi-UAV surveillance implementation under hierarchical dynamic task scheduling architecture [J]. Journal of Central South University, 2020, 27(9): 2614–2627. DOI: https://doi.org/10.1007/s11771-020-4486-8.

KHEDDAR A, CARON S, GERGONDET P, COMPORT A. Humanoid robots in aircraft manufacturing: The airbus use cases [J]. IEEE Robotics & Automation Magazine, 2019, 26(4): 30–45. DOI: https://doi.org/10.1109/MRA.2019.2943395.

ROGERS J R. Low-cost teleoperable robotic arm [J]. Mechatronics, 2009, 19(5): 774–779. DOI: https://doi.org/10.1016/j.mechatronics.2009.03.004.

BAI Ke-qiang, LUO Min-zhou, LI Tao, WU Jue. The impulse excitation joint servo drive design and adaptive back stepping control of humanoid robots [J]. Journal of Bionic Engineering, 2018, 15(1): 114–125. DOI: https://doi.org/10.1007/s42235-017-0009-1.

GOPINATH V, JOHANSEN K, DERELOV M. GUSTAFSSON A, AXELSSON S. Safe collaborative assembly on a continuously moving line with large industrial robots [J]. Robotics and Computer-Integrated Manufacturing, 2021. DOI: https://doi.org/10.1016/j.rcim.2020.102048.

SATHYAN A, MILIVOJEVIC N, LEE Y J, KRISHNAMURTHY M, EMADI A. An FPGA-based novel digital PWM control scheme for BLDC motor drives [J]. IEEE Transactions on Industrial Electronics, 2009, 56(8): 3040–3049. DOI: https://doi.org/10.1109/TIE.2009.2022067.

XIA Chang-liang, LI Zhi-qiang, SHI Ting-na. A control strategy for four-switch three phase brushless DC motor using single current sensor [J]. IEEE Transactions on Industrial Electronics, 2009, 56: 2058–2066. DOI: https://doi.org/10.1109/TIE.2009.2014307.

DUBEY R, AGARWAL P, VASANTHA M K. Programmable logic devices for motion control—A review [J]. IEEE Transactions on Industrial Electronics, 2007, 54(1): 559–566. DOI: https://doi.org/10.1109/TIE.2006.885452.

CHENG Kuang-yao, ZOU Ying-yu. Design of a sensorless commutation IC for BLDC motors [J]. IEEE Transactions on Power Electronics, 2003, 18(6): 1365–1375. DOI: https://doi.org/10.1109/TPEL.2003.818867.

TATSCH C, AHMADI A, BOTTEGA F, TANI J, GUERRA R D. Dimitri: An open-source humanoid robot with compliant joint [J]. Journal of Intelligent & Robotic Systems, 2018, 91(2): 291–300. DOI: https://doi.org/10.1007/s10846-017-0727-y.

HU Yuan, GUO Wei-zhong. A new concept of contact joint to model the geometric foot-environment contacts for efficiently determining possible stances for legged robots [J]. Mechanism and Machine Theory, 2021, 162. DOI: https://doi.org/10.1016/j.mechmachtheory.2021.104327.

YAGI K, MORI Y, MOCHIYAMA H. Force-sensorless human hint impedance estimation utilizing impulsive force [J]. Advanced Robotics, 2020, 35(6): 349–358. DOI: https://doi.org/10.1080/01691864.2020.1861976.

BUJA G, BERTOLUZZO M, KESHRI R K. Torque ripple-free operation of PM BLDC drives with petal-wave current supply [J]. IEEE Transactions on Industrial Electronics, 2015, 62(7): 4034–4043. DOI: https://doi.org/10.1109/TIE.2014.2385034.

USMAN A, RAJPUROHIT B S. Modeling and classification of stator inter-turn fault and demagnetization effects in BLDC motor using rotor back-EMF and radial magnetic flux analysis [J]. IEEE Access, 2020, 8: 118030–118049. DOI: https://doi.org/10.1109/ACCESS.2020.3005038.

LU Wen-qi, WU Ya-xiong, ZHU De-ming, LU Kai-yuan, WANG Dong, YE Mao-sheng. A new short-time high-overload BLDC driving system based on electronic flywheel and time-division switching control [J]. Mechatronics, 2020, 69. DOI: https://doi.org/10.1016/j.mechatronics.2020.102385.

MAYO A P, SAENZ-AGUIRRE A, MARTIN F, VADILLO J. FOC-Droop control strategy for PMSM fed paralleled multi-inverter power systems oriented to aeronautical applications [J]. Electric Power Systems Research, 2020, 185(1): 106369. DOI: https://doi.org/10.1016/j.epsr.2020.106369.

MO Shuai, ZHANG Ting, JIN Guo-guang, CAO Xiao-lin, GAO Han-jun. Analytical investigation on load sharing characteristics of herringbone planetary gear train with flexible support and floating sun gear [J]. Mechanism and Machine Theory, 2020, 144(2): 1–27. DOI: https://doi.org/10.1016/j.mechmachtheory.2019.103670.

MO Shuai, ZHANG Yi-du, WU Qiong. Research on multiple-split load sharing of two-stage star gearing system in consideration of displacement compatibility [J]. Mechanism and Machine Theory, 2015, 88(1): 1–15. DOI: https://doi.org/10.1016/j.mechmach-theory.2015.01.005.

MO Shuai, ZHANG Yi-du, WU Qiong, HOUJOH H, MATSUMURA S. Research on natural characteristics of double-helical star gearing system for GTF aero-engine [J]. Mechanism and Machine Theory, 2016, 106(12): 166–189. DOI: https://doi.org/10.1016/j.mechmachtheory.2016.09.001.

LIU J, PANG R K, LI H W, XU J. Influence of support stiffness on vibrations of a planet gear system considering ring with flexible support [J]. Journal of Central South University, 2020, 27(8): 2280–2290. DOI: https://doi.org/10.1007/s11771-020-4449-0.

BOUKHALFA G, BELKACEM S, CHIKHI A, BENAGGOUNE S. Genetic algorithm and particle swarm optimization tuned fuzzy PID controller on direct torque control of dual star induction motor[J]. 2019, 26(7): 1886–1896. DOI: https://doi.org/10.1007/s11771-019-4142-3.

Funding

Project(51805368) supported by the National Natural Science Foundation of China; Project(2018QNRC001) supported by the Young Elite Scientists Sponsorship Program by China Association for Science and Technology; Project (DMETKF2021017) supported by Open Fund of State Key Laboratory of Digital Manufacturing Equipment and Technology, Huazhong University of Science and Technology, China

Author information

Authors and Affiliations

Corresponding author

Additional information

Contributors

MO Shuai provided the concept and edited the draft of manuscript. LI Xu conducted the literature review and wrote the first draft of the manuscript. YANG Zhen-ning, ZHOU Chang-peng, GAO Han-jun, CEN Guo-jian, and HUANG Yun-sheng edited the draft of manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

MO Shuai, LI Xu, YANG Zhen-ning, ZHOU Chang-peng, GAO Han-jun, CEN Guo-jian, and HUANG Yun-sheng declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Mo, S., Li, X., Yang, Zn. et al. Integrated design of brushless motor drive and control system for robot joints. J. Cent. South Univ. 28, 3818–3828 (2021). https://doi.org/10.1007/s11771-021-4884-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4884-6