Abstract

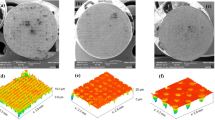

Chrome steels are used in bearings since they possess high strength and wear resistance. However, when those parts are in service, failure happens due to sliding friction before the lifetime. To improve the durability of the American Iron and Steel Institute (AISI) 52100 chromium steel, in this work, the effect of laser surface texturing (LST) was analyzed. With the different patterns of circle and ellipse comparing with the untextured samples, the wear behavior was investigated using the pin-on-disc tribometer. The lubricant used for wear analysis is semisolid lithium grease National Lubricating Grease Institute lubricant (SKF NLGI-3). Sliding wear analysis was conducted at different loads of 10 N, 30 N and 50 N for the sliding speed of 750 r/min and 1400 r/min. The wear morphology was analyzed using a scanning electron microscope(SEM). The roughness of the samples was found using a white light interferometer. The effect of different patterns like circle and ellipse, alter the friction and wear properties of chromium alloy was observed compared with the untextured samples. LST shows considerable reduction in friction and wear for ellipsoidal pattern compared with the circular pattern because of wear debris and lubricant getting trapped.

摘要

铬钢因具有高强度和耐磨性而用于轴承。然而,在实际使用中,因滑动摩擦导致的故障而使 寿命缩短。为了提高AISI52100 铬钢材料的耐久性,本文分析了激光表面纹理(LST)化的效果。利 用圆盘摩擦,对不同形状,如椭圆和圆,与未纹理化处理试样的磨损行为进行了对比研究。用于磨损 分析的润滑剂是SKFNLGI-3 半固体锂基润滑脂。在10、30 和50 N 的不同载荷下,用750 r/min 和1400 r/min 2 种滑动速度进行滑动磨损分析。用扫描电子显微镜(SEM)对磨损形貌进行了分析。样品的粗糙 度用白光干涉仪测量。与未纹理化处理试样相比,观察到不同形状如圆和椭圆对铬合金摩擦磨损性能 的影响。由于磨损碎片和润滑剂被捕获,激光表面纹理显示椭圆的摩擦和磨损与圆形图案相比,明显 减少。

Similar content being viewed by others

References

LU Li-bin, ZHANG Zhen, GUAN Ying-chun, ZHENG Hong-yu. Comparison of the effect of typical patterns on friction and wear properties of chromium alloy prepared by laser surface texturing [J]. Optics and Laser Technology, 2018, 106: 272–279. DOI: https://doi.org/10.1016/j.optlastec.2018.04.020.

ETSION I, KLIGERMAN Y, HALPERIN G. Analytical and experimental investigation of laser-textured mechanical seal faces [J]. Tribology Transactions, 1999, 42: 511–516. DOI: https://doi.org/10.1080/10402009908982248.

SHARMA N, KANGO S, SHARMA R K, SUNIL N A. Investigations on the effects of surface texture on the performance of a porous journal bearing operating with couple stress fluids [J]. International Journal of Surface Science and Engineering, 2014, 8: 392–407. DOI: https://doi.org/10.1504/IJSURFSE.2014.065817.

SHARMA N, SHARMA R K, SUNIL N A, KANGO S. A comparative study for lubrication of surface textured porous journal bearing with two different non-Newtonian fluid models [J]. International Journal of Surface Science and Engineering, 2016, 10: 485–502. DOI: https://doi.org/10.1504/IJSURFSE.2016.079045.

GACHOT C, ROSENKRANZ A, HSU S M, COSTA H L. A critical assessment of surface texturing for friction and wear improvement [J]. Wear, 2017, 372: 21–41. DOI: https://doi.org/10.1016/j.wear.2016.11.020.

QIU M, DELIC A, RAEYMAEKERS B. The effect of texture shape on the load-carrying capacity of gas-lubricated parallel slider bearings [J]. Tribology Letters, 2012, 48: 315–327.

DINESH BABU P, VIGNESH S, VIGNESH M, BALAMURUGAN C. Enhancement of wear resistance of Ti-6Al-4V alloy by picosecond laser surface micro texturing process [J]. Journal of Central South University, 2018, 25(8): 1836–1848. DOI: https://doi.org/10.1007/s11771-018-3873-x.

FIASCHI G, DI LAURO M, BALLESTRAZZI A, ROTA A, BISCARINI F, VALERI S. Tribological response of laser-textured steel pins with low-dimensional micrometric patterns [J]. Tribology International, 2019, 149: 105548. DOI: https://doi.org/10.1016/j.triboint.2019.01.007.

BAI Li-chun, SRIKANTH N, KORZNIKOVA E A, BAIMOVA J A, DMITRIEV S V, ZHOU Kun. Wear and friction between smooth or rough diamond-like carbon films and diamond tips [J]. Wear, 2017, 373: 12–20. DOI: https://doi.org/10.1016/j.wear.2016.12.007.

ZHANG Zhao, LU Wen-zhuang, HE Ya-feng, ZHOU Guang-hui. Research on optimal laser texture parameters about antifriction characteristics of cemented carbide surface [J]. International Journal of Refractory Metals and Hard Materials, 2019, 82: 287–296. DOI: https://doi.org/10.1016/j.ijrmhm.2019.05.008.

BURSTEIN L, INGMAN D. Pore ensemble statistics in application to lubrication under reciprocating motion [J]. Tribology Transactions, 2000, 43: 205–212. DOI: https://doi.org/10.1080/10402000008982330.

NANBU T, REN N, YASUDA Y, ZHU D, WANG Q J. Micro-textures in concentrated conformal-contact lubrication: Effects of texture bottom shape and surface relative motion [J]. Tribology Transactions, 2008, 29: 241–252. DOI: https://doi.org/10.1007/s11249-008-9302-9.

WANG X L, HSU S M. An integrated surface technology for friction control: Az new paradigm effects of geometric shapes on friction [C]// The 4th China International Symposium on Tribology. Xi’an, 2004: 12–20.

CHEN Ping, LI Jun-ling, SHI Zhe, XIANG Xin. Numerical optimization of gourd-shaped surface texture and experiment of tribological performance [J]. Journal of Central South University, 2017, 24: 2773–2782. DOI: https://doi.org/10.1007/s1171-017-3691-6.

ZHAI Wen-zheng, ZHOU Kun. Nanomaterials in superlubricity [J]. Advanced Functional Materials, 2019, 29: 1–19. DOI: https://doi.org/10.1002/adfm.201806395.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paul Joshua, S., Dinesh Babu, P. Effect of laser textured surface with different patterns on tribological characteristics of bearing material AISI 52100. J. Cent. South Univ. 27, 2210–2219 (2020). https://doi.org/10.1007/s11771-020-4442-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4442-7