Abstract

A numerical optimization approach based on the finite element (FE) simulation was used to design the optimum irregular gourd-shaped pattern parameters for generating the highest hydrodynamic pressure. Then the optimum parameters of the gourd-shaped surface texture were determined and the textures were processed on the stainless steel surface by the laser technology. The tribological performance of gourd-shaped surface texture was analyzed using the type of UMT2 tester, and compared with that of the regular circle surface texture and none-texture surface by considering the effect of sliding speeds and applied loads on the tribological performance. The results show that the compound factor n, the diameter ratio Dr and the texture depth Hd are more significant parameters and the optimum values are 0.618, 2.0 and 4 μm, respectively. In addition, irregular gourd-shaped surface texture with optimum parameters is the most effective in the friction reduction among the patterns investigated under different speeds and applied loads in this work. Moreover, better coordination and combination effect can be obtained by gourd-shaped surface texture. The main reason responsible for the results is the irregular symmetric nature of the gourd-shaped texture along the direction of lubricants flowing which can generate the higher fluid dynamic pressure.

Similar content being viewed by others

References

WANG Xiao-lei, ADACHI K, OTSUKA K, KATO K. Optimization of the surface texture for silicon carbide sliding in water [J]. Applied Surface Science, 2006, 253: 1282–1286.

QIU Ming-feng, DELIC A, RAEYMAEKERS B. The effect of texture shape on the load-carrying capacity of gas-lubricated parallel slider bearings [J]. Tribology Letters, 2012, 48(3): 315–327.

SHAO Tian-min, GENG Zhe. Research progress in patterned thin solid techniques and their tribological performance [J]. China Surface Engineering, 2015, 28(2): 1–26. (in Chinese)

RAPOPORT L, MOSHKOVICH A, PERFILYEV V, GEDANKEN A, KOLTYPIN Y, SOMINSKI E, HALPERIN G, ETSION I. Wear life and adhesion of solid lubricant films on laser-textured steel surfaces [J]. Wear, 2009, 267: 1203–1207.

LIN Qi-yin, WEI Zheng-ying, WANG Ning, CHEN Wei. Effect of large-area texture/slip surface on journal bearing considering cavitation [J]. Industrial Lubrication and Tribology, 2015, 67(3): 216–226.

DE MELLO J D B, GONCALVES J L Jr, COSTA H L. Influence of surface texturing and hard chromium coating on the wear of steels used in cold rolling mill rolls [J]. Wear, 2013, 302: 1295–1309.

ELKOCA O. A study on the characteristics of electrical discharge textured skin pass mill work roll [J]. Surface & Coatings Technology, 2008, 202(12): 2765–2774.

UTSCH M, VINKE P. EDT: Roll texturing technology as a base of modern surfaces in automotive cold mill flat products [J]. Iron & Steel Technology, 2005, 2(9): 50–55.

WAN Da-ping, LIU Hong-bin, WANG Yu-ming, HU De-jin, GUI Zhen-xing. CO2 laser beam modulating for surface texturing machining [J]. Optics & Laser Technology, 2008, 40(2): 309–314.

WU Wei, CHEN Gui-ming, ZHAO Na, FAN Bo-xuan. Experimental study on the groove surface texture processed by laser on the surface of high-speed steel [J]. Infrared and Laser Engineering, 2016, 45(2): 206008.

GARCÍA G T G, GARZA M T V, GARZA A Q, ZUAZUA D V, CORTÉS D M, TELLEZ A M, ZAMARRÓN R B. Development of a methodology for improving the tribological properties in die processing using laser surface texturing [J]. Tribologia, 2014, 3: 47–58.

CHEN Ping, XIANG Xin, SHAO Tian-min, LA Ying-qian, LI Jun-ling. Effect of triangular texture on the tribological performance of die steel with TiN coatings under lubricated sliding condition [J]. Applied Surface Science, 2016, 389: 361–368.

SHEN Huan, CHEN Guang-nan, LI Guo-chen. The plastic instability behaviour of laser-textured steel sheet [J]. Materials Science and Engineering A, 1996, 219(1): 156–161.

JI Jing-hu, WANG Hao, FU Yong-hong. Effect of elliptical dimples on hydrodynamic lubrication [J]. Key Engineering Materials, 2015, 645–646: 474–479.

YUAN Si-huan, HUANG Wei, WANG Xiao-lei. Orientation effects of micro-grooves on sliding surfaces [J]. Tribology International, 2011, 44(9): 1047–1054.

ZUMGAHR K H, WAHL R, WAUTHIER K. Experimental study of the effect of microtexturing on oil lubricated ceramic/steel friction pairs [J]. Wear, 2009, 267(5): 1241–1251.

XING You-qiang, DENG Jian-xin, WU Ze, CHENG Hong-wei. Effect of regular surface textures generated by laser on tribological behavior of Si3 N4/TiC ceramic [J]. Applied Surface Science, 2013, 265: 823–832.

SHEN Cong, KHONSARI M M. Numerical optimization of texture shape for parallel surfaces under unidirectional and bidirectional sliding [J]. Tribology International, 2015, 82: 1–11.

LI Jun-ling, CHEN Ping, SHAO Tian-min, XIANG Xin. The effect of gourd-shaped surface texture on tribological performance of stainless steel [J]. Tribology, 2016, 36(2): 207–214. (in Chinese)

CHEN Ping, LI Jun-ling, SHAO Tian-min, XIANG Xin, LIU Guang-lei. Optimal analysis of geometric parameters of surface texture with surface tension considered [J]. Journal of Mechanical Engineering, 2016, 52(19): 123–131. (in Chinese)

WANG Xiao-lei, HAN Wen-fei, KATO K. Surface texture optimal design for silicon carbide under water lubrication [J]. Chinese Journal of Mechanical Engineering, 2008, 19(2): 457–460. (in Chinese)

WANG Xiao-lei, KATO K, ADACHI K, AIZAWA K. Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water [J]. Tribology International, 2003, 36(3): 189–197.

ETSION I, KLIGERMAN Y, HALPERIN G. Analytical and experimental investigation of laser-textured mechanical seal faces [J]. Tribology Transactions, 1999, 42(3): 511–516.

RUAN Hong-yan, LV Jian-jun, SI Hui, LIU Hui-xia, WANG Xiao. Hydrodynamic lubrication performance on multi-textured surface structured by multi-arcs and triangle textures [J]. Journal of Jiangsu University, 2010, 31(3): 254–258. (in Chinese)

SEGU D Z, CHOI S G, CHOI J H, KIM S S. The effect of multi-scale laser textured surface on lubrication regime [J]. Applied Surface Science, 2013, 270: 58–63.

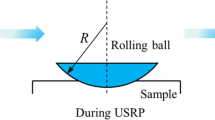

KOVALCHENKO A, AJAYI O, ERDEMIR A, FENSKE G, ETISON I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact [J]. Tribology International, 2005, 38(3): 219–225.

MENEZES P L, KISHORE, KAILAS S V. Influence of surface texture and roughness parameters on friction and transfer layer formation during sliding of aluminium pin on steel plate [J]. Wear, 2009, 267(9, 10): 1534–1549.

HUANG Wei, JIANG Liang, ZHOU Chuan-xi, WANG Xiao-lei. The lubricant retaining effect of micro-dimples on the sliding surface of PDMS [J]. Tribology International, 2012, 52(3): 87–93.

XIONG Dang-sheng, QIN Yong-kun, LI Jian-liang, WAN Yi, TYAGI R. Tribological properties of PTFE/laser surface textured stainless steel under starved oil lubrication [J]. Tribology International, 2015, 82: 305–310.

Acknowledgement

The authors would like to express special thanks to Tian-min SHAO (State Key Laboratory of Tribology, Tsinghua University) for scientific guidance and English writing assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51305023) supported by the National Natural Science Foundation of China; Project(FRF-GF-17-B20) supported by the Fundamental Research Funds for the Central Universities of China

Rights and permissions

About this article

Cite this article

Chen, P., Li, Jl., Shi, Z. et al. Numerical optimization of gourd-shaped surface texture and experiment of tribological performance. J. Cent. South Univ. 24, 2773–2782 (2017). https://doi.org/10.1007/s11771-017-3691-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-017-3691-6