Abstract

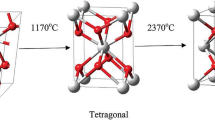

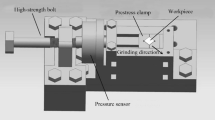

Zirconia has been used in medical applications since last few years and an optimum and cost-effective condition in grinding zirconia has drawn industrial attention. This paper aimed to improve and control the surface integrity, flexural strength and grinding cost in grinding partially stabilized zirconia (PSZ) using a diamond grinding wheel. The phase transition and grindability of PSZ were also evaluated. Ground surfaces analysis shows that all samples subjected to the grinding presented an increase in surface integrity, and the subsurface damages 100 below the surface were reduced from 3.4% to 0.9%. The flexural strength using 3 point bending test (3PB) shows that grinding increased the flexural strength more than 29% which is the result of higher surface integrity. The ground surfaces were analyzed using X-ray diffraction (XRD) and the results shows that T-M phase transition trend is in accordance with the surface integrity. In other words, XRD analyses prove that T-M phase transition results in higher flexural strength and surface integrity. It was also observed that in the best condition, the grinding cost was reduced by 72%. It can be concluded that controlling the grinding condition in grinding PSZ will result in the increase of the surface integrity and flexural strength. A mathematical model was created to find an optimum condition using response surface method (RSM). It is observed that feed rate has greater effect on the outputs rather than depth of cut.

摘要

近年来氧化锆一直被应用于医学领域,如何获得优化、低成本的氧化锆磨削条件引起了工业界 的关注。本文使用金刚石砂轮磨削部分稳定氧化锆(PSZ),以提高和控制其表面完整性、弯曲强度和 磨削成本,并研究PSZ 的相变和可研磨性。通过表面分析发现,所有经过磨削的样品表面完整性都有 所增加,表面下100 μm 的表面损伤从3.4%降到了0.9%。弯曲强度试验表明,弯曲强度提高了29% 以上,这是由于磨削获得了较高的表面完整性。用进行X RD 表面分析发现,T-M 相变趋势与表面完 整性一致,即T-M 相变可以提高弯曲强度和表面完整性。而且在最佳条件下,磨削成本降低了72%。 因此,控制磨削PSZ 中的磨削条件可以改善表面完整性和弯曲强度。利用响应表面法(RSM)建立数学 模型来获得最优条件,发现进给量对输出的影响大于切削深度。

Similar content being viewed by others

References

SIKALIDIS C. Advances in ceramics: electric and magnetic ceramics, bioceramics, ceramics and environment [M]. London: Intech Open Publication, 2011.

NISTOR L, GRADINARU M, RICA R, MARASESCU P, STAN M, MANOLEA H, IONESCU A, MORARU I. Zirconia use in dentistry-manufacturing and properties [J]. Current Health Sciences Journal, 2019, 45(1): 28–35.

FLINN B D, RAIGRODSKI A J, MANCL L A, TOIVOLA R, KUYKENDALL T. Influence of aging on flexural strength of translucent zirconia for monolithic restorations [J]. The Journal of Prosthetic Dentistry, 2017, 117(2): 303–309. DOI: https://doi.org/10.1016/j.prosdent.2016.06.010.

XU S, YAO Z, HE J, XU J. Grinding characteristics, material removal, and damage formation mechanisms of zirconia ceramics in hybrid laser/grinding [J]. Journal of Manufacturing Science and Engineering, 2018, 140(7): 071010. DOI: https://doi.org/10.1115/1.4039645.

ANAND P S, ARUNACHALAM N, VIJAYARAGHAVAN L. Performance of diamond and SiC wheels on grinding of bioceramic material under MQL condition [J]. Journal of Manufacturing Science and Engineering, 2017, 139(12): 121019. DOI: https://doi.org/10.1115/1.4037940.

YANG M, LI C, ZHANG Y, JIA D, LI R, HOU Y, CAO H. Effect of friction coefficient on chip thickness models in ductile-regime grinding of zirconia ceramics [J]. The International Journal of Advanced Manufacturing Technology, 2019, 102: 2617–2632. DOI: https://doi.org/10.1007/s00170-019-03367-0.

NIKZAD S, AZARI A, NIKAN S, BAHRANI Z. Current status of zirconia in dentistry: An overview [J]. Journal of Dental Medicine, 2014, 27(3): 223–232.

ADÁNEZ M H, NISHIHARA H, ATT W. A systematic review and meta-analysis on the clinical outcome of zirconia implant-restoration complex [J]. Journal of Prosthodontic Research, 2018, 62(4): 397–406. DOI: https://doi.org/10.1016/j.jpor.2018.04.007.

GEHRKE S A, da SILVA P M, GUIRADO J L, DELGADORUIZ R A, DEDAVID B A, NAGASAWA M A, SHIBLI J A. Mechanical behavior of zirconia and titanium abutments before and after cyclic load application [J]. The Journal of Prosthetic Dentistry, 2016, 116(4): 529–535. DOI: https://doi.org/10.1016/j.prosdent.2016.02.015.

SHAHRAMIAN K, LEMINEN H, MERETOJA V, LINDERBÄCK P, KANGASNIEMI I, LASSILA L, NÄRHI T. Sol-gel derived bioactive coating on zirconia: Effect on flexural strength and cell proliferation [J]. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 2017, 105(8): 2401–2407. DOI: https://doi.org/10.1002/jbm.b.33780.

REED J S, ANNE-MARIE L. Affect of grinding and polishing on near-surface phase transformations in zirconia [J]. Materials Research Bulletin, 1977, 12(10): 949–954. DOI: https://doi.org/10.1016/0025-5408(77)90017-4.

OZER F, NADEN A, TURP V, MANTE F, SEN D, BLATZ M B. Effect of thickness and surface modifications on flexural strength of monolithic zirconia [J]. The Journal of Prosthetic Dentistry, 2018, 119(6): 987–993. DOI: https://doi.org/10.1016/j.prosdent.2017.08.007.

XU S, YAO Z, CAI H, WANG H. An experimental investigation of grinding force and energy in laser thermal shock-assisted grinding of zirconia ceramics [J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(9–12): 3299–3306. DOI: https://doi.org/10.1007/s00170-017-0013-y.

POLLI G S, HATANAKA G R, de OLIVEIRA A F, de SOUZA G M, REIS J M. Fatigue behavior and surface characterization of a Y-TZP after laboratory grinding and regeneration firing [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2018, 88: 305–312. DOI: https://doi.org/10.1016/j.jmbbm.2018.08.019.

NIE Zhen-guo, WANG Gang, JIANG Feng, LIN Yong-liang, RONG Yi-ming. Investigation of modeling on single grit grinding for martensitic stainless steel [J]. Journal of Central South University, 2018, 25(8): 1862–1869. DOI: https://doi.org/10.1007/s11771-018-3875-8.

ZHAO Pei-yi, ZHOU Ming, ZHANG Yuan-jing, QIAO Guo-chao. Surface roughness prediction model in ultrasonic vibration assisted grinding of BK7 optical glass [J]. Journal of Central South University, 2018, 25(2): 277–286. DOI: https://doi.org/10.1007/s11771-018-3736-5.

CHEN Jiang, ZHAO Hang, ZHANG Fei-hu, ZHANG Yuan-jing, ZHANG Yong. Mechanism underlying formation of SSC in optical glass due to dynamic impact of single diamond scratch [J]. Journal of Central South University, 2015, 22(11): 4146–4153. DOI: https://doi.org/10.1007/s11771-015-2961-4.

WANG Hong-xiang, HOU Jing, WANG Jing-he, ZHU Ben-wen, ZHANG Yan-hu. Experimental investigation of subsurface damage depth of lapped optics by fluorescent method [J]. Journal of Central South University, 2018, 25(7): 1678–1689. DOI: https://doi.org/10.1007/s11771-018-3859-8.

LI P, JIN T, GUO Z, YI J, QU M. Analysis on the effects of grinding wheel speed on removal behavior of brittle optical materials [J]. Journal of Manufacturing Science and Engineering, 2017, 139(3): 031014. DOI: https://doi.org/10.1115/1.4034665.

ZUCUNI C P, DAPIEVE K S, RIPPE M P, PEREIRA G K, BOTTINO M C, VALANDRO L F. Influence of finishing/polishing on the fatigue strength, surface topography, and roughness of an yttrium-stabilized tetragonal zirconia polycrystals subjected to grinding [J]. Journal of the Mechanical Behavior of Biomedical Materials, 2019, 93: 222–229. DOI: https://doi.org/10.1016/j.jmbbm.2019.02.013.

BECHCINSKI G, EWAD H, TSIAKOUMIS V, PAWLOWSKI W, KEPCZAK N, MCMILLAN A, BATAKO A D. A model and application of vibratory surface grinding [J]. Journal of Manufacturing Science and Engineering, 2018, 140(10): 101011. DOI: https://doi.org/10.1115/1.4040725.

SOLHTALAB A, ADIBI H, ESMAEILZARE A, REZAEI S M. Cup wheel grinding-induced subsurface damage in optical glass BK7: An experimental, theoretical and numerical investigation [J]. Precision Engineering, 2019. DOI: https://doi.org/10.1016/j.precisioneng.2019.04.003.

ABOUSHELIB M N, SALEM N A, TALEB A L, el MONIEM N M. Influence of surface nano-roughness on osseointegration of zirconia implants in rabbit femur heads using selective infiltration etching technique [J]. Journal of Oral Implantology, 2013, 39(5): 583–590. DOI: https://doi.org/10.1563/AAID-JOI-D-11-00075.

KHALILI M R, ZIAIE B, KAZEMI M. Finite element analysis for dental implants subjected to thermal loads [J]. Journal of Dental Medicine, 2013, 26(4): 270–280.

GITTENS R A, OLIVARES-NAVARRETE R, TANNENBAUM R, BOYAN B D, SCHWARTZ Z. Electrical implications of corrosion for osseointegration of titanium implants [J]. Journal of Dental Research, 2011, 90(12): 1389–1397. DOI: https://doi.org/10.1177/0022034511408428.

WNEK G E, BOWLIN G L. Encyclopedia of biomaterials and biomedical engineering [M]. 2nd ed. New York: Taylor and Francis, 2014.

LI Z, ZHENG K, LIAO W, XIAO X. Surface characterization of zirconia ceramics in ultrasonic vibration-assisted grinding [J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2018, 40(8): 1–9. DOI: https://doi.org/10.1007/s40430-018-1296-0.

LEE D H, MAI H N, THANT P P, HONG S H, KIM J, JEONG S M, LEE K W. Effects of different surface finishing protocols for zirconia on surface roughness and bacterial biofilm formation [J]. The Journal of Advanced Prosthodontics, 2019, 11(1): 41–47. DOI: https://doi.org/10.4047/jap.2019.11.1.41.

STRICKSTROCK M, ROTHE H, GROHMANN S, HILDEBRAND G, ZYLLA I M, LIEFEITH K. Influence of surface roughness of dental zirconia implants on their mechanical stability, cell behavior osseointegration [J]. Bio Nano Materials, 2017, 18(1–2). DOI: https://doi.org/10.1515/bnm-2016-0013.

GARVIE R, HANNINK R, PASCOE R. Ceramic steel? [J], Nature, 1975, 258: 703–704. DOI: https://doi.org/10.1038/258703a0.

XU H, SAID J, LEWIS K I. Effect of grinding on strength of tetragonal zirconia and zirconia-toughened alumina [J]. Machining Science and Technology, 1997, 1(1): 49–66. DOI: https://doi.org/10.1080/10940349708945637

SHIH A J, GRANT M B, YONUSHONIS T M, MORRIS T O, MCSPADDEN S B. Vitreous bond CBN wheel for high speed grinding of zirconia and M2 tool steel [J]. Transactions-North American Manufacturing Research Institution of SME, 1998: 195–200.

CURRY A C, SHIH A J, KONG J, SCATTERGOOD R O, MCSPADDEN S B. Grinding temperature measurements in magnesia partially stabilized zirconia using infrared spectrometry [J]. Journal of the American Ceramic Society, 2003, 86(2): 333–341. DOI: https://doi.org/10.1111/J.1151-2916.2003.tb00019.x.

IŞERI U, ÖZKURT Z, KAZAZOĞLU E, KÜÇÜKOĞLU D. Influence of grinding procedures on the flexural strength of zirconia ceramics [J]. Brazilian Dental Journal, 2010, 21(6): 528–532. DOI: https://doi.org/10.1590/S0103-64402010000600008

CHEN J, SHEN J, HUANG H, XU X. Grinding characteristics in high speed grinding of engineering ceramics with brazed diamond wheels [J]. Journal of Materials Processing Technology, 2010, 210(6): 899–906. DOI: https://doi.org/10.1016/j.jmatprotec.2010.02.002.

YANG M, LI C, ZHANG Y, JIA D, ZHANG X, HOU Y, LI R, WANG J. Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions [J]. International Journal of Machine Tools and Manufacture, 2017, 122: 55–65. DOI: https://doi.org/10.1016/j.ijmachtools.2017.06.003.

QEBLAWI D M, MUÑOZ C A, BREWER J D, MONACO E A Jr. The effect of zirconia surface treatment on flexural strength and shear bond strength to a resin cement [J]. The Journal of Prosthetic Dentistry, 2010, 103(4): 210–220. DOI: https://doi.org/10.1016/S0022-3913(10)60033-9.

le GUÉHENNEC L, SOUEIDAN A, LAYROLLE P, AMOURIQ Y. Surface treatments of titanium dental implants for rapid osseointegration [J]. Dental Materials, 2007, 23(7): 844–854. DOI: https://doi.org/10.1016/j.dental.2006.06.025.

ANAND P, ARUNACHALAM N, VIJAYARAGHAVAN L. Grinding behavior of yttrium partially stabilized zirconia using diamond grinding wheel [J]. Advanced Materials Research, 2016, 1136: 15–20. DOI: https://doi.org/10.4028/www.scientific.net/AMR.806.15.

MALKIN S, GUO C. Grinding technology: Theory and application of machining with abrasives. [M]. New York: Industrial Press Inc., 2008.

SUZUKI K, UEMATSU T, NAKAGAWA T. On-machine trueing/dressing of metal bond grinding wheels by electro-discharge machining [J]. CIRP Annals, 1987, 36(1): 115–118. DOI: https://doi.org/10.1016/S0007-8506(07)62566-9.

HOSOKAWA A, UEDA T, YUNOKI T. Laser dressing of metal bonded diamond wheel [J]. CIRP Annals, 2006, 55(1): 329–332. DOI: https://doi.org/10.1016/S0007-8506(07)60428-4.

KOPAC J, KRAJNIK P. High-performance grinding—A review [J]. Journal of Materials Processing Technology, 2006, 175(1): 278–284. DOI: https://doi.org/10.1016/j.jmatprotec.2005.04.010.

CHUSOVITINA T V, YU S. TOROPOV, TRETNIKOVA M G. Properties of ceramics based on zirconia partly stabilized with yttrium concentrate [J]. Refractories and Industrial Ceramics, 1991, 32(5): 277–279. DOI: https://doi.org/10.1007/BF01290392.

ISO14704. Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Test Method for Flexural Strength of Monolithic Ceramics at Room Temperature. International Organization for Standards, Geneva, Switzerland, 2008 [S].

ICHIDA Y. Creep feed profile grinding of Ni-based superalloys with ultrafine-polycrystalline CBN abrasive grits [J]. Precision Engineering, 2001, 25(4): 274–283. DOI: https://doi.org/10.1016/S0141-6359(01)00078-2.

PLATT A, FRANKEL P, GASS M, HOWELLS R, PREUSS M. Finite element analysis of the T-M phase transformation during oxidation of zirconium alloys [J]. Journal of Nuclear Materials, 2014, 454(1–3): 290–292. DOI: https://doi.org/10.1016/j.jnucmat.2014.08.020.

Acknowledgements

This project is supported by the Centre of Advanced Manufacturing and Material Processing of University of Malaya.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khodaii, J., Barazandeh, F., Rezaei, S.M. et al. Surface integrity and flexural strength improvement in grinding partially stabilized zirconia. J. Cent. South Univ. 26, 3261–3278 (2019). https://doi.org/10.1007/s11771-019-4251-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4251-z