Abstract

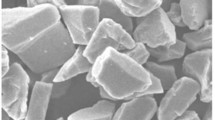

Non lubricated slide performance of functional grade copper matrix composite, fabricated using horizontal centrifuge cast technique was investigated using pin-on-disc tribo-tester. Rate of wear and friction coefficient of the inner wall thickness of hollow cylindrical cast specimen was analyzed using Taguchi based L27 orthogonal array, where the percentage of graphite particles were observed higher. Variable process parameters those influenced the rate of wear directly or indirectly were: applied load (15, 25 and 35 N), slide velocity (1.5, 2.5 and 3.5 m/s) and slide distance (750, 1500 and 2250 m). Rate of wear and friction coefficient showed a proportional dependency with applied load and slide distance, whereas showing a decline during intermediate slide velocity. Signal-to-Noise ratio predicted the minimal tribo-condition, on ‘smaller-the-better’ basis. Analysis of Variance technique quantified the influence of affecting parameters, along with their interactions. Regression analysis was utilized for the validation of the experimental data. Micrographs and scanning electron microscopy exhibited the wear mechanisms and mechanically mixed layer formation during worn surfaces analysis.

摘要

采用水平离心铸造工艺, 制备功能梯度铜基复合材料, 并对其非润滑滑动性能进行了研究. 采用基于Taguchi 的L27 正交实验对石墨颗粒含量较高的空心圆柱铸件内壁厚度的磨损速率和摩擦系数进行分析. 直接或间接影响磨损速率的工艺参数包括: 施加的载荷(15, 25 和35 N)、滑动速度(1.5, 2.5 和3.5 m/s)和滑动距离(750, 1500 和2250 m). 磨损速率和摩擦系数与施加的载荷和滑动距离呈比例的依赖性, 而在中间滑动速度期间表现出下降. 信噪比在“较小-较好”的基础上预测最小三波条件. 方差分析量化参数的影响及其相互作用. 采用回归分析对实验数据进行验证. 在磨损表面分析过程中, 通过显微镜和扫描电子显微镜发现磨损机制和机械混合层的形成.

Similar content being viewed by others

References

KOMPOZITOV T I, SUHEM P. The friction and wear behavior of Cu-Ni3Al composites by dry sliding [J]. Materials and Technology, 2011, 45(5): 401–406.

MANU S, RADHIKA N. Effect of heat treatment on mechanical and tribological properties of centrifugally cast functionally graded Cu/Al2O3 composite [J]. Journal of Tribology, 2018, 140(2): 021606.

GANGWAR S, BHAT I K, PATNAIK A. Tribological and microstructure examination of environmental waste (marble dust) filled silicon bronze alloy for wear resistant applications [J]. Silicon, 2017, 9(2): 249–263.

RALPH B, YUEN H C, LEE W B. The processing of metal matrix composites—An overview [J]. Journal of Materials Processing Technology, 1997, 63(1–3): 339–353.

HASHIM J, LOONEY L, HASHMI M S. Metal matrix composites: Production by the stir casting method [J]. Journal of Materials Processing Technology, 1999, 92: 1–7.

KENNEDY F E, BALBAHADUR A C, LASHMORE D S. The friction and wear of Cu-based silicon carbide particulate metal matrix composites for brake applications [J]. Wear, 1997, 203: 715–721.

KATO H, TAKAMA M, IWAI Y, WASHIDA K, SASAKI Y. Wear and mechanical properties of sintered copper—tin composites containing graphite or molybdenum disulfide [J]. Wear, 2003, 255(1–6): 573–578.

DESHPANDE P K, LIN R Y. Wear resistance of WC particle reinforced copper matrix composites and the effect of porosity [J]. Materials Science and Engineering A, 2006, 418 (1, 2)}: 137–145.

ROHATGI P K, RAY S, LIU Y. Tribological properties of metal matrix-graphite particle composites [J]. International Materials Reviews, 1992, 37(1): 129–152.

KOVÁČIK J, EMMER Š, BIELEK J. Effect of composition on friction coefficient of Cu—graphite composites [J]. Wear, 2008, 265 (3, 4)}: 417–421.

DEVINCENT S M, MICHAL G M. Reaction layer formation at the graphite/copper-chromium alloy interface [J]. Metallurgical Transactions A, 1993, 24(1): 53–60.

RIAHI A R, ALPAS A T. The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites [J]. Wear, 2001, 251(2): 1396–1407.

MOUSTAFA S F, EL-BADRY S A, SANAD A M, KIEBACK B. Friction and wear of copper—graphite composites made with Cu-coated and uncoated graphite powders [J]. Wear, 2002, 253 (7, 8)}: 699–710.

CAO H, QIAN Z, ZHANG L, XIAO J, ZHOU K. Tribological behavior of Cu matrix composites containing graphite and tungsten disulphide [J]. Tribology Transactions, 2014, 57(6): 1037–1043.

GULTEKIN D, UYSAL M, ASLAN S, ALAF M, GULER M O, AKBULUT H. The effects of applied load on the coefficient of friction in Cu-MMC brake pad/Al-SiCp MMC brake disc system [J]. Wear, 2010, 270 (1, 2)}: 73–82.

DAOUD A, EL-KHAIR M A. Wear and friction behavior of sand cast brake rotor made of A359-20 vol% SiC particle composites sliding against automobile friction material [J]. Tribology International, 2010, 43(3): 544–553.

ÜNLÜ B S, ATIK E. Evaluation of effect of alloy elements in copper based CuSn10 and CuZn30 bearings on tribological and mechanical properties [J]. Journal of Alloys and Compounds, 2010, 489(1): 262–268.

MOHANDAS A, RADHIKA N. Studies on mechanical behaviour of aluminium/nickel coated silicon carbide reinforced functionally graded composite [J]. Tribology in Industry, 2017, 39(2): 145–151.

DINAHARAN I, SATHISKUMAR R, MURUGAN N. Effect of ceramic particulate type on microstructure and properties of copper matrix composites synthesized by friction stir processing [J]. Journal of Materials Research and Technology, 2016, 5(4): 302–316.

TJONG S C, LAU K C. Tribological behaviour of SiC particle-reinforced copper matrix composites [J]. Materials Letters, 2000, 43 (5, 6)}: 274–280.

UTHAYAKUMAR M, ARAVINDAN S, RAJKUMAR K. Wear performance of Al—SiC—B4C hybrid composites under dry sliding conditions [J]. Materials & Design, 2013, 47: 456–464.

ZHANG G, SCHLARB A K. Morphologies of the wear debris of polyetheretherketone produced under dry sliding conditions: Correlation with wear mechanisms [J]. Wear, 2009, 266 (7, 8)}: 745–752.

ZHANG L, HE X B, QU X H, DUAN B H, LU X, QIN M L. Dry sliding wear properties of high volume fraction SiCp/Cu composites produced by pressure-less infiltration [J]. Wear, 2008, 265 (11, 12)}: 1848–1856.

GUL F, ACILAR M. Effect of the reinforcement volume fraction on the dry sliding wear behaviour of Al—10Si/SiCp composites produced by vacuum infiltration technique [J]. Composites Science and Technology, 2004, 64 (13, 14)}: 1959–1970.

MANU S, RADHIKA N. Development of functionally graded Cu-Sn-Ni/Al2O3 composite for bearing applications and investigation of its mechanical and wear behaviour [J]. Particulate Science and Technology, 2018, 1: 1–12.

BHATIJA K A, RADHIKA N. Studies on sliding wear characteristics of aluminium LM25/silicon dioxide functionally graded composite and optimisation of parameters using response surface methodology [J]. Materialwissenschaft und Werkstofftechnik, 2017, 48(6): 600–610.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(ERIP/ER/1503188/M/01/1587) supported by the Financial and Technological Support from Defense Research and Development Organization-DRDO, India

Rights and permissions

About this article

Cite this article

Radhika, N., Sam, M. Tribological and wear performance of centrifuge cast functional graded copper based composite at dry sliding conditions. J. Cent. South Univ. 26, 2961–2973 (2019). https://doi.org/10.1007/s11771-019-4228-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4228-y