Abstract

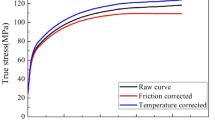

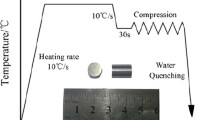

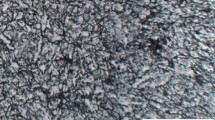

In order to study the effect of dynamic recrystallization on the metal flow behavior during thermal deformation, the elevated temperature compression experiments of CuCrZr alloy and 35CrMo steel are carried out using Gleeble-3810 thermal simulator. It is proved that the samples underwent obvious dynamic recrystallization behavior during thermal deformation by microstructure observation of deformed specimens. The size of recrystallized grains increases as the temperature improved and the strain rate decreased. Meanwhile, the net softening rate caused by dynamic recrystallization is determined based on the stress-dislocation relationship. It can be found that the value of net softening rate increases quadratically as the Z parameter decreases, and the dynamic recrystallization net softening rate of CuCrZr alloy and 35CrMo steel are calculated to be 21.9% and 29.8%, respectively. Based on the dynamic recrystallization softening effect proposed, the novel elevated temperature flow constitutive models of two different alloys are proposed, and the related parameters are well defined and solved in detail. The predicted values of the obtained models are agreed well with the experimental values.

摘要

为了研究热变形过程中动态再结晶对金属流变行为的影响,采用Gleeble-3800 热模拟机对 CuCrZr 合金和35CrMo 钢进行了高温压缩实验。通过观察热变形后样品的金相组织,证明了样品在热 变形过程中经历了明显的动态再结晶,且动态再结晶晶粒尺寸随着变形温度的升高和应变速率的降低 而增大。以应力-位错密度的关系为理论依据,定义了由动态再结晶所引起的净软化作用η。η 与 Z 参 数之间呈三次递减关系。计算得到的CuCrZr 合金和35CrMo 钢的最大η 值分别为21.9%和29.8%。基 于所提出的动态再结晶软化效应,构建了两种合金的高温流动行为本构模型。并对模型参数进行了定 义和求解。所建模型的预测值与实验所得的数据高度吻合。

Similar content being viewed by others

References

SUN Chao-yang, LUAN Jing-dong, LIU Geng, LI Rui, ZHANG Qing-dong. Predicted constitutive modeling of hot deformation for AZ31 magnesium alloy [J]. Acta Metallurgica Sinica, 2012, 48(7): 853–860. DOI: 10.3724/ SP.J.1037.2011.00641.

GU Bin, PENG Yan. Constitutive relationships of Nb microalloyed steel during high temperature deformation [J]. Acta Metallurgica Sinica, 2011, 47(4): 507–512. DOI: 10.1007/s1 1460-011-0118-2.

WEI Hai-lian, LIU Guo-quan, ZHANG Ming-he. Physically based constitutive analysis to predict flow stress of medium carbon and vanadium microalloyed steels [J]. Materials Science and Engineering A, 2014, 602: 127–133. DOI: 10.1016/j.msea.2014.02.068.

WANG San-xing, HUANG Yuan-chun, LIU Yu, LIU Hui. A modified Johnson-Cook model for hot deformation behavior of 35CrMo Steel [J]. Metals, 2017, 7(9): 337. DOI: 10.3390/met7090337.

ETAATI A, DEHGHANI K. A study on hot deformation behavior of Ni-42.5Ti-7.5Cu alloy [J]. Materials Chemistry and Physics, 2013, 140(1): 208–215. DOI: 10.1016/j.matchemphys.2013.03.022.

DONAHUE E G, ODETTE G R. A physically based constitutive model for a V-4Cr-4Ti alloy [J]. Journal of Nuclear Materials, 2000, 283: 637–641. DOI: 10.1016/ S0022-3115(00)00275-0.

HAMED M. A comparative study on the hot flow stress of Mg-Al-Zn magnesium alloys using a simple physically-based approach [J]. Journal of Magnesium and Alloys, 2014, 2(3): 225–229. DOI: 10.1016/j.jma.2014.09.003.

LIN Y C, CHEN Xiao-ming, WEN Dong-xu, CHEN Ming-song. A physically-based constitutive model for a typical nickel-based superalloy [J]. Computational Materials Science, 2014, 83: 282–289. DOI: 10.1016/j.commatsci. 2013.11.003.

ZHU Rui-hua, LIU Qing, LI Jing-fei, XIANG Sheng, CHEN Yong-lai, ZHANG Xu-hu. Dynamic restoration mechanism and physically based constitutive model of 2050 Al-Li alloy during hot compression [J]. Journal of Alloys and Compounds, 2015, 650: 75–85. DOI: 10.1016/j.jallcom. 2015.07.182.

DONG Ding-qian, CHEN Fei, CUI Zhen-shan. A physically-based constitutive model for SA508-III steel: Modeling and experimental verification [J]. Materials Science and Engineering A, 2015, 634: 103–115. DOI: 10.1016/j.msea. 2015.03.036.

HE An, XIE Gan-lin, YANG Xiao-ya, WANG Xi-tao, ZHANG Hai-long. A physically-based constitutive model for a nitrogen alloyed ultralow carbon stainless steel [J]. Computational Materials Science, 2015, 98: 64–69. DOI: 10.1016/j.commatsci.2014.10.044.

QIAN Dong-sheng, PENG Ya-ya, DENG Jia-dong. Hot deformation behavior and constitutive modeling of Q345E alloy steel under hot compression [J]. Journal of Central South University, 2017, 24(2): 284–295. DOI: 10.1007/ S11771-017-3429-5.

LIN Y C, CHEN Xiao-ming, LIU Ge. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel [J]. Materials Science and Engineering A, 2010, 527(26): 6980–6986. DOI: 10.1016/ j.msea.2010.07.061.

LIN Y C, CHEN Ming-song, ZHONG Jue. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel [J]. Computational Materials Science, 2008, 42(3): 470–477. DOI: 10.1016/j.commatsci.2007.08.011.

YIN Fei, HUA Lin, MAO Hua-jie, HAN Xing-hui. Constitutive modeling for flow behavior of GCrl5 steel under hot compression experiments [J]. Materials and Design, 2013, 43: 393–401. DOI: 10.1016/j.matdes.2012.07.009.

HAGHDADI N, ZAREI-HANZAKI A, ABEDI H R. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strain [J]. Materials Science and Engineering A, 2012, 535: 252–257. DOI: 10.1016/j.msea.2011.12.076.

SPIGARELLI S, MEHTEDI M E, RICCI P, MAPELLI C. Constitutive equations for prediction of the flow behaviour of duplex stainless steels [J]. Materials Science and Engineering A, 2010, 527(16, 17): 4218–4228. DOI: 10.1016/j.msea.2010.03.029.

MIRZADEH H, NAJAFIZADEH A, MOAZENY M. Flow curve analysis of 17-4 PH stainless steel under hot compression test [J]. Metallurgical and Materials Transactions A, 2009, 40(12): 2950–2958. DOI: 10.1007/ S11661-009-0029-5.

JI Guo-liang, LI Fu-guo, LI Qing-hua, LI Hui-qu, LI Zhi. Prediction of the hot deformation behavior for Aermet 100 steel using an artificial neural network [J]. Computational Materials Science, 2010, 48(3): 626–632. DOI: 10.1016/j.commatsci.2010.02.031.

JI Guo-liang, LI Fu-guo, LI Qing-hua, LI Hui-qu, LI Zhi. A comparative study on Arrhenius-type constitutive model and artificial neural network model to predict high-temperature deformation behaviour in AermetlOO steel [J]. Materials Science and Engineering A, 2011, 528(13, 14): 4774–4782. DOI: 10.1016/j.msea.2011.03.017.

BOBBILI R, RAMUDU B V, MADHU V. A physically-based constitutive model for hot deformation of Ti-10-2-3 alloy [J]. Journal of Alloys and Compounds, 2016, 696: 295–303. DOI: 10.1016/j.jallcom.2016.11.208.

GANDIN C A, RAPPAZ M. A coupled finite element-cellular automaton model for the prediction of dendritic grain structures in solidification processes [J]. Acta Metallurgica Et Materialia, 1994, 42(7): 2233–2246. DOI: 10.1016/0956-7151(94)90302-6.

GURUSAMY M M, RAO B C. On the performance of modified Zerilli-Armstrong constitutive model in simulating the metal-cutting process [J]. Journal of Manufacturing Processes, 2017, 28(1): 253–265. DOI: 10.1016/j.jmapro. 2017.06.011.

LI Fu-guo, WANG Rui-ting, JI Guo-liang, YUAN Zhan-wei. Comparative investigation on the modified Zerilli-Armstrong model and Arrhenius-type model to predict the elevated-temperature flow behaviour of 7050 aluminium alloy [J]. Computational Materials Science, 2013, 71(3): 56–65. DOI: 10.1016/j.commatsci.2013.01.010.

HUANG Yuan-chun, LI Ming, XIAO Zheng-bing, LIU Hui, WANG Sang-xing. A dynamic recrystallization (DRX) constitutive model for elevated temperature flow behavior of Cu-0.5Cr-0.1Zr Alloy [J]. Metallography, Microstructure, and Analysis, 2018, 8(1): 45–57. DOI: 10.1007/sl3632-018-0502-x.

XIAO Zheng-bing, HUANG Yuan-chun, LIU Yu. Evolution of dynamic recrystallization in 35CrMo steel during hot deformation [J]. Journal of Materials Engineering and Performance, 2018, 27(3): 1–9. DOI: 10.1007/sl 1665-018-3220-2.

KLEPACZKO J R, CHIEM C Y On rate sensitivity of f.c.c. metals, instantaneous rate sensitivity and rate sensitivity of strain hardening [J]. Journal of the Mechanics and Physics of Solids, 1986, 34(1): 29–54. DOI: 10.1016/0022-5096(86)90004-9.

ESTRIN Y, MECKING H. A unified phenomenological description of work hardening and creep based on one-parameter models [J]. Acta Metallurgica, 1984, 32(1): 57–70. DOI: 10.1016/0001-6160(84)90202-5.

MECKING H, KOCKS U F. Kinetics of flow and strain-hardening [J]. Acta Metallurgica, 1981, 29(11): 1865–1875. DOI: 10.1016/0001-6160(81)90112-7.

SELLARS C M, MCTEGART W J. On the mechanism of hot deformation [J]. Acta Metallurgica, 1966, 14(9): 1136–1138. DOI: 10.1016/0001-6160(66)90207-0.

SELLARS C M. The kinetics of softening processes during hot working of austenite [J]. Czechoslovak Journal of Physics B, 1985, 35(3): 239–248. DOI: 10.1007/ BF01605090.

ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel [J]. Journal of Applied Physics, 1944, 15(1): 0–22. DOI: 10.1063/1.1707363.

JONAS J J, SELLARS C M, TEGART W J M. Strength and structure under hot-working conditions [J]. Metallurgical Reviews, 1969, 14(1): 1–24. DOI: 10.1179/mtlr.l969.14.1.1.

MEYSAMI M, MOUSAVI S A A A. Study on the behavior of medium carbon vanadium microalloyed steel by hot compression test [J]. Materials Science and Engineering A, 2011, 528(7, 8): 3049–3055. DOI: 10.1016/j.msea.2010. 11.093

BAMBACH M. Implications from the Poliak-Jonas criterion for the construction of flow stress models incorporating dynamic recrystallization [J]. Acta Materialia, 2013, 61(16): 6222–6233. DOI: 10.1016/j.actamat.2013.07.006.

LIANG Guo-quan, GUO Hong-zhen, NING Yong-quan. Dynamic recrystallization behavior of Ti-5Al-5Mo-5V-1Cr-1Fe alloy [J]. Materials and Design, 2014, 63: 798–804. DOI: 10.1016/j.matdes.2014.06.064.

POLIAK E I, JONAS J J. Initiation of dynamic recrystallization in constant strain rate hot deformation [J]. ISIJ International, 2007, 43(5): 684–691. DOI: 10.2355/isijinternational.43.684.

MIRZADEH H, NAJAFIZADEH A. Prediction of the critical conditions for initiation of dynamic recrystallization [J]. Materials and Design, 2010, 31(3): 1174–1179. DOI: 10.1016/j.matdes.2009.09.038.

POLIAK E I, JONAS J J. A one-parmenter approach to determining the critical conditions for the initiation of dynamic recrystallization [J]. Acta Materialia, 1996, 44(1): 127–136. DOI: 10.1016/1359-6454(95)00146-7.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2019zzts525) supported by the Fundamental Research Funds for the Central Universities, China; Projects(U1837207, U1637601) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Huang, Yc., Li, M., Ma, Cq. et al. Flow behaviour constitutive model of CuCrZr alloy and 35CrMo steel based on dynamic recrystallization softening effect under elevated temperature. J. Cent. South Univ. 26, 1550–1562 (2019). https://doi.org/10.1007/s11771-019-4111-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-019-4111-x

Key words

- CuCrZr alloy

- 35CrMo steel

- dynamic recrystallization

- dynamic recrystallization softening effect

- high temperature flow constitutive model