Abstract

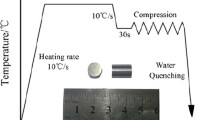

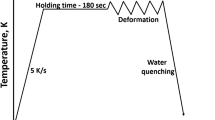

The hot deformation behavior of 20MnNiMo low carbon alloy was investigated by isothermal compression tests over wide ranges of temperature (1223-1523 K) and strain rate (0.01-10 s-1). According to the experimental true stress-true strain data, the constitutive relationships were comparatively studied based on the Arrhenius-type model, Johnson-Cook (JC) model and artificial neural network (ANN), respectively. Furthermore, the predictability of the developed models was evaluated by calculating the correlation coefficient (R) and mean absolute relative error (AARE). The results indicate that the flow stress behavior of 20MnNiMo low carbon alloy is significantly influenced by the strain rate and deformation temperature. Compared with the Arrhenius-type model and Johnson-Cook (JC) model, the ANN model is more efficient and has much higher accuracy in describing the flow stress behavior during hot compressing deformation for 20MnNiMo low carbon alloy.

Similar content being viewed by others

References

LIANG Wen-jie, PAN Qing-lin, HE Yun-bin, LI Yun-chun, ZHANG Xiao-gang. Flow stress behavior of Al-Cu-Li-Zr alloy containing Sc during hot compression deformation [J]. Journal of Central South University of Technology, 2008, 15(3): 289–294.

LI Bo, PAN Qing-lin, LI Chen, ZHANG Zhi-ye, YIN Zhi-min. Hot compressive deformation behavior and constitutive relationship of Al-Zn-Mg-Zr alloy with trace amounts of Sc [J]. Journal of Central South University, 2013, 20(11): 2939–2946.

JI Hong-chao, LIU Jin-ping, WANG Bao-yu, ZHANG Zheng-rong, ZHANG Tao, HU Zheng-huan. Numerical analysis and experiment on cross wedge rolling and forging for engine valves [J]. J Mater Process Tech, 2015, 221: 233–242.

LI Xu, WANG Hong-yu, DING Jing-guo, LI Xu, WANG Hong-yu, DING Jing-guo, XU Jiu-jing, ZHANG Dian-hua. Analysis and prediction of fishtail during V-H hot rolling process [J]. Journal of Central South University, 2015, 22(4): 1184–1190.

SAREBANZADEH M, MAHMUDI R, ROUMINA R. Constitutive analysis and processing map of an extruded Mg-3Gd-1Zn alloy under hot shear deformation [J]. Mater Sci Eng A, 2015, 18: 155–161.

WEI Feng, FU You-heng. High temperature deformation behavior and constitutive modeling for 20CrMnTiH steel [J]. Mater Des, 2014, 57: 465–471.

LI Li, LI Hui-zhong, LIANG Xiao-peng, HUANG Lan, HONG Tao. Flow stress behavior of high purity Al-Cu-Mg alloy and microstructure evolution [J]. Journal of Central South University, 2015, 22(3): 815–820.

LIN Yong-cheng, DING Yi, CHEN Ming-song, DENG Jiao. A new phenomenological constitutive model for hot tensile deformation behaviors of a typical Al-Cu-Mg alloy [J]. Mater Des, 2013, 52: 118–127.

ZENG Zhi-peng, JONSSON S, ZHANG Yan-shu. Constitutive equations for pure titanium at elevated temperatures [J]. Mater Sci Eng A, 2009, 505: 116–119.

LI Bo, PAN Qing-lin, YIN Zhi-min. Microstructural evolution and constitutive relationship of Al-Zn-Mg alloy containing small amount of Sc and Zr during hot deformation based on Arrhenius-type and artificial neural network models [J]. J Alloy Compd, 2014, 584: 406–416.

LUO Jiao, LI Miao-quan, LI Xiao-li, SHI Yan-pei. Constitutive model for high temperature deformation of titanium alloys using internal state variables [J]. Mech Mater, 2010, 42: 157–165.

HAN Ying, QIAO Guan-juan, SUN Jia-peng, ZOU De-ning. A comparative study on constitutive relationship of as-cast 904L austenitic stainless steel during hot deformation based on Arrhenius-type and artificial neural network models [J]. Comput Mater Sci, 2013, 67: 93–103.

ZHAO Jing-wei, HUA Ding, ZHAO Wen-juan, HUANG Ming-li, WEI Dong-bin, JIANG Zheng-yi. Modelling of the hot deformation behaviour of a titanium alloy using constitutive equations and artificial neural network [J]. Comput Mater Sci, 2014, 92: 47–56.

LIN Yong-cheng, ZHANG Jun, ZHONG Jue. Application of neural networks to predict the elevated temperature flow behavior of a low alloy steel, Comput [J]. Mater Sci, 2008, 43: 752–758.

LIN Yong-cheng, CHEN Xiao-min. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working [J]. Mater Des, 2011, 32: 1733–1759.

SUN Yu, ZENG Wei-dong, HAN Yuan-fei, MA Xiong, ZHAO Yong-qing, GUO Ping, WANG Gui, DARGUSCH M S. Determination of the influence of processing parameters on the mechanical properties of the Ti-6Al-4V alloy using an artificial neural network [J]. Comput Mater Sci, 2012, 60: 239–244.

GUPTA A K, SINGH S K, REDDY S, HARIHARAN G. Prediction of flow stress in dynamic strain aging regime of austenitic stainless steel 316 using artificial neural network [J]. Mater Des, 2012, 35: 589–595.

MANDAL S, SIVAPRASAD P V, VENUGOPAL S, MURTHY K P N, RAJ B. Artificial neural network modeling of composition process property correlations in austenitic stainless steels [J]. Mat Sci Eng A, 2008, 485: 571–580.

WANG Meng-han, LI Yu-feng, WANG Wen-hao, ZHOU Jie, AKIHIKO C. Quantitative analysis of work hardening and dynamic softening behavior of low carbon alloy steel based on the flow stress [J]. Mater Des, 2013, 45: 384–392.

KIM M C, PARK S G, LEE K H, LEE B S. Comparison of fracture properties in SA508 Gr.3 and Gr.4N high strength low alloy steels for advanced pressure vessel materials [J]. Inter J Pres Ves Pip, 2015, 131: 60–66.

MING Hong-liang, ZHANG Zhi-ming, WANG Jian-qiu, HAN En-hou, KE Wei. Microstructural characterization of an SA508-309L/308L-316L domestic dissimilar metal welded safe end joint [J]. Mater Charact, 2014, 97: 101–115.

LEE K H, KIM M C, YANG W J, LEE B S. Evaluation of microstructural parameters controlling cleavage fracture [J]. Mater Sci Eng A, 2013, 565: 158–164.

ZHANG Chi, ZHANG Li-wen, SHEN Wei-fei, LI Meng-fei, GU Sen-dong. Characterization of hot deformation behavior of Hastelloy C-276 using constitutive equation and processing map [J]. J Mater Eng Perform, 2014, 24: 149–157.

CAI Jun, WANG Kuai-she, ZHAI Peng, LI Fu-guo, YANG Jie. A modified Johnson-cook constitutive equation to predict hot deformation behavior of Ti-6Al-4V alloy [J]. J Mater Eng Perform, 2014, 24: 32–44.

ZENER C, HOLLOMON J. Effect of strain rate upon plastic flow of steel [J]. J Appl Phys, 1944, 15: 22–32.

LIN Yong-cheng, CHEN Ming-song, ZHONG Jue. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel [J]. Computational Materials Science, 2008, 42: 470–477.

SPIGARELLI S, EL MEHTEDI M. A new constitutive model for the plastic flow of metals at elevated temperatures [J]. J Mater Eng Perform, 2013, 23: 658–665.

ABBASI-BANI A, ZAREI-HANZAKI A, PISHBIN M H, HAGHDADI N. A comparative study on the capability of Johnson-Cook and Arrhenius-type constitutive equations to describe the flow behavior of Mg-6Al-1Zn alloy [J]. Mech Mater, 2014, 71: 52–61.

CHEN Liang, ZHAO Guo-qun, YU Jun-quan. Hot deformation behavior and constitutive modeling of homogenized 6026 aluminum alloy [J]. Mater Des, 2015, 74: 25–35.

LIN Yong-cheng, LI Qi-fei, XIA Yu-chi, LI Lei-ting. A phenomenological constitutive model for high temperature flow stress prediction of Al-Cu-Mg alloy [J]. Mater Sci Eng A, 2012, 534: 654–662.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(CDJZR14130006) supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Wang, Mh., Wang, Gt. & Wang, R. Flow stress behavior and constitutive modeling of 20MnNiMo low carbon alloy. J. Cent. South Univ. 23, 1863–1872 (2016). https://doi.org/10.1007/s11771-016-3241-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3241-7