Abstract

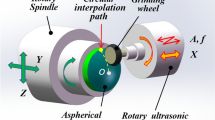

During the grinding of optical glass, the abrasion directly affects the morphology and depth of subsurface cracks (SSC). The effect of dynamic impact of grinding abrasives on optical glass is an important issue in the field of optics manufacturing. In this work, a single diamond scratch was used to grind optical glass, and grinding parameters were collaboratively controlled to ensure that the cutting layer remained constant. A dynamometer was used to record the duration of the impact process, and the cross-section of the test piece was polished for scanning electron microscopy (SEM) to determine the depth of the SSCs. The experimental results show that as wheel speed increases, SSC depth tends to decrease. When the wheel speed gradually increases from 500 r/min to 2500 r/min, the probability distribution curve for the maximum SSC depth shifts downward by around 80 μm. The effect of the dynamic impact of single diamond scratch is found to be an important cause of SSC formation in optical glass during grinding, i.e., the faster the grinding, the shallower the SSCs.

Similar content being viewed by others

References

BOUZID S, NYOUNGUE A, AZARI Z, BOUAOUADJA N, PLUVINAGE G. Fracture criterion for glass under impact loading [J]. International Journal of Impact Engineering, 2001, 25: 831–845.

FAN L F, REN F, MAN G W. An extended displacement discontinuity method for analysis of stress wave propagation in viscoelastic rock mass [J]. Journal of Rock Mechanics and Geotechnical Engineering, 2011, 3(1): 1–9.

GORWADE C V, ASHCROFT I A. Experimental and numerical analysis of stress wave propagation in polymers and the role of interfaces in armour systems [J]. Central European Journal of Engineering, 2012, 2(4): 578–584.

LI Chong, ZHANG Jing-chao, WANG Xin-wei. Phase change and stress wave in picosecond laser–material interaction with shock wave formation [J]. Apply Phys A, 2013, 112: 677–687.

DAI Zi-hua, ZHU Yong-wei, WANG Jian-bin, JU Zhi-lan, LIU Yun-feng. Measurement of sub-surface damage of K9 Mass by step-by-step etching method [J]. Optics and Precision Engineering, 2013, 21(2): 287–293. (in Chinese)

WANG Li-li. Foundation of stress waves [M]. Beijing: National Defense Industry Press, 2010: 227–240. (in Chinese)

ZHAI Chao-jiao, XIA Tang-dai, DU Guo-qing, DING Zhi. Dynamic response of cylindrical cavity to anti-plane impact load by using analytical approach [J]. Journal of Central South University, 2014, 21(1): 405–415.

HU Liu-qing, LI Xi-bing. Damage and fragmentation of rock under experiencing impact load [J]. Journal of Central South University, 2006, 13(4): 432–437.

JIN Jie-fang, LI Xi-bing, WANG Guan-shi. YIN Zhi-qiang. Failure modes and mechanisms of sandstone under cyclic impact loadings [J]. Journal of Central South University: Science and Technology, 2012, 43(4): 1453–1461. (in Chinese)

ZHANG Hong, GAO Qian, XU Bin. Scattering wave field around a cavity with circular cross-section embedded in saturated soil using boundary element method [J]. Journal of Central South University, 2013, 20(8): 3296–3304.

LI Sheng-yi, WANG Zhou, WU Yu-lie, DAI Yi-fan. Prediction theory and experiment of subsurface damage based on lapping processing parameters [J]. Journal of Mechanical Engineering, 2009, 45(2): 192–198. (in Chinese)

WANG Wei, LAI Yong-xing, MIAO Tong-chen, LI Jing-bin. Vibration mechanics and engineerin applications [M]. Zhengzhou: Zhengzhou University Press, 2008: 51–53. (in Chinese)

LAMBROPOULOS J C, JACOBS S D, GILLMAN B E. Deterministic microgrinding lapping and polishing of glass-ceramics [J]. J Am Ceram Soc, 2005, 88(5): 1127–1132.

GUVEN U. The investigation of the nonlocal longitudinal stress waves with modified couple stress theory [J]. Acta Mech, 2011, 221: 321–325.

YOUSSEF G, GUPTA V. Resonance in polyurea-based multilayer structures subjected to laser-generated stress waves [J]. Experimental Mechanics, 2013, 53: 145–154.

CHEN Jiang, ZHANG Fei-hu, ZHAO Hang. Study on the mechanism of optical glass sub-surface crack formation in single abrasive grinding [J]. Key Engineering Materials, 2012, 523–524: 1–6.

CHEN Jiang, ZHANG Fei-hu, ZHAO Hang. Study on numerical simulation of the dynamic impact effect for optical glass grinding with single grit [C]// Proceeding of SPIE 8415, 6th International Symposium on Aduanced Optical Manufacturing and Testing Technologies: Large Mirrors and Telescopes Xiamen, China: SPIE, 2012: 841515.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51175126) supported by National Natural Science Foundation of China (NSFC); Project(2011CB013202) supported by the National Basic Research Program (973 Program) of China

Rights and permissions

About this article

Cite this article

Chen, J., Zhao, H., Zhang, Fh. et al. Mechanism underlying formation of SSC in optical glass due to dynamic impact of single diamond scratch. J. Cent. South Univ. 22, 4146–4153 (2015). https://doi.org/10.1007/s11771-015-2961-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2961-4