Abstract

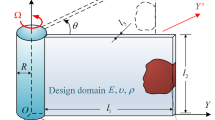

In order to study the bending behavior of aluminum alloy 7050 thick plate during snake hot rolling, several coupled thermo-mechanical finite element (FE) models were established. Effects of different initial thicknesses, pass reductions, speed ratios and offset distances on the bending value of the plate were analyzed. ‘Quasi smooth plate’ and optimum offset distance were defined and quasi smooth plate could be acquired by adjusting offset distance, and then bending control equation was fitted. The results show that bending value of the plate as well as the extent of the increase grows with the increase of pass reduction and decrease of initial thickness; the bending value firstly increases and then keeps steady with the ascending speed ratio; the bending value can be reduced by enlarging the offset distance. The optimum offset distance varies for different rolling parameters and it is augmented with the increase of pass reduction and speed ratio and the decrease of initial thickness. A proper offset distance for different rolling parameters can be calculated by the bending control equation and this equation can be a guidance to acquire a quasi smooth plate. The FEM results agree well with experimental results.

Similar content being viewed by others

References

LI Xing-dan. Development of commercial aircraft aluminum alloy structural materials [J]. Shanghai Nonferrous Metals, 1994, 15(3): 160–168. (in Chinese)

WANG Zhu-tang. World aluminum foils rolling industry [M]. Changsha: Central South University Press, 2010: 40. (in Chinese)

YANG Shi-de. Introduction of asymmetric aluminum hot rolling and mill [J]. World Nonferrous Metals, 2010(2): 47. (in Chinese)

FU Yao. Study on snake rolling of aluminum alloy thick plate with high strength and high toughness [D]. Beijing Nonferrous Metal Research Institute, 2011. (in Chinese)

ZHANG Jin-ling, CUI Zhen-shan. Continuous FEM simulation of multi-pass plate hot rolling suitable for plate shape analysis [J]. Journal of Central South University of Technology, 2011, 18(1):16–22.

WANG Zhi-kui, ZHANG Qing. Numerical simulation of involutes spline shaft in cold rolling forming [J]. Journal of Central South University of Technology, 2008, 15(Supplement 2):278–283.

CAO Jian-guo, XU Xiao-zhao, ZHANG Jie, SONG Mu-qing, GONG Gui-liang, ZENG Wei. Preset model of bending force for 6-high reversing cold rolling mill based on genetic algorithm [J]. Journal of Central South University of Technology, 2011, 18(5):1487–1492.

CAO Guang-ming, LI Cheng-gang, ZHOU Guo-ping, LIU zhen-yu, WU Di, WANG Guo-dong, LIU Xiang-hua. Rolling force prediction for strip casting using theoretical model and artificial intelligence [J]. Journal of Central South University of Technology, 2010, 17(4):795–800.

LU J, HARRER O, SCHWENZFEIER W. Analysis of the bending of the rolling material in asymmetrical sheet rolling [J]. International Journal of Mechanical Sciences, 2000, 42(1):49–61.

KNIGHT C W, HARDY S J, LEES A W. Influence of roll speed mismatch on strip curvature during the roughing stages of a hot rolling mill [J]. Journal of Materials Processing Technology, 2005, 168(1):184–188.

KNIGHT C W, HARDY S J, LEES A W. Investigations into the influence of asymmetric factors and rolling parameters on strip curvature during hot rolling [J]. Journal of Materials Processing Technology, 2003, 134(2):180–189.

FARHAT-NIA F, SALIMI M, MOVAHHEDY M R. Elasto-plastic finite element simulation of asymmetrical plate rolling using an ALE approach [J]. Journal of Materials Processing Technology, 2006, 177(1):525–529.

YANG Dai-jun, HU Xiong-guang, LIU Guang-ming, LIU Jing-zhi, YAN Zhi-ping. Finite element simulation analysis of plate curvature during medium plate rolling [J]. Mechanical Science and Technology, 2006, 25(1): 36–38. (in Chinese)

HAO L, DI H, GONG D. Analysis of sheet curvature in asymmetrical cold rolling [J]. Journal of Iron and Steel Research, International, 2013, 20(5):34–37.

PHILIPP M, SCHWENZFEIER W, FISCHER F D. Front end bending in plate rolling influenced by circumferential speed mismatch and geometry [J]. Journal of Materials Processing Technology, 2007, 184(1):224–232.

RICHELSEN A B. Elastic-plastic analysis of the stress and strain distributions in asymmetric rolling [J]. International Journal of Mechanical Sciences, 1997, 39(11):1199–1211.

LI Xue-tong, DU Feng-shan, WANG Min-ting, ZHANG Xiao-feng. Nonlinear FEM study of head end curling in plate rolling [J]. Journal of Iron and Steel Research, 2005, 17(5): 43–47. (in Chinese)

LI Liang, DU Feng-shan, GUO Zhen-yu, ZHANG Jian-min, WU Jian-feng, ZHANG Xiao-feng. Analytical and FEM simulation of the front end bending in asymmetrical hot plate rolling [J]. Metallurgical Equipment, 2003(2): 4–7. (in Chinese)

LI Xue-wen. Finite element modeling of deformation in AA7050 during asymmetrical rolling with speed match and horizontal displacement [D]. Changsha: Central South University, 2013. (in Chinese)

FU Yao, XIE Shui-sheng, XIONG Bo-qing, HUANG Guo-jie, CHENG Lei, XIAO Xiang-peng. Analytical study of plate curvature in snake rolling of aluminum alloy [J]. Chinese Journal of Rare Metals, 2011, 35(6): 805–811. (in Chinese)

FU Yao, XIE Shui-sheng, XIONG Bo-qing, HUANG Guo-jie, CHENG Lei. Effect of rolling parameters on plate curvature during snake rolling [J]. Journal of Wuhan University of Technology (Materials Science Edition), 2012, 27(2):247–251.

YI You-ping, YANG Ji-hui, LIN Yong-cheng. Flow stress constitutive equation of 7050 aluminum alloy during hot compression [J]. Journal of Materials Engineering, 2007(4): 20–22. (in Chinese)

WANG Jing-zhong. Research status on head curling in plate rolling [J]. Journal of Xi’an University of Architecture & Technology (Natural Science Edition), 2011, 43(2): 294–300. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Projects(2012CB619505, 2010CB731703) supported by the National Basic Research Program of China; Project(CX2013B065) supported by Hunan Provincial Innovation Foundation for Postgraduate, China; Project(51405520) supported by the National Natural Science Foundation of China; Project(zzyjkt2013-06B) supported by the State Key Laboratory of High Performance Complex Manufacturing (Central South University), China

Rights and permissions

About this article

Cite this article

Zhang, T., Wu, Yx., Gong, H. et al. Bending analysis and control of rolled plate during snake hot rolling. J. Cent. South Univ. 22, 2463–2469 (2015). https://doi.org/10.1007/s11771-015-2774-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2774-5